Three-dimensional interconnection hybrid network structure and fabrication method and application

A technology of network structure and three-dimensional interconnection, applied in the field of electrodes, can solve problems such as poor conductivity, and achieve the effects of improving electronic conductivity, increasing active surface area, and good rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

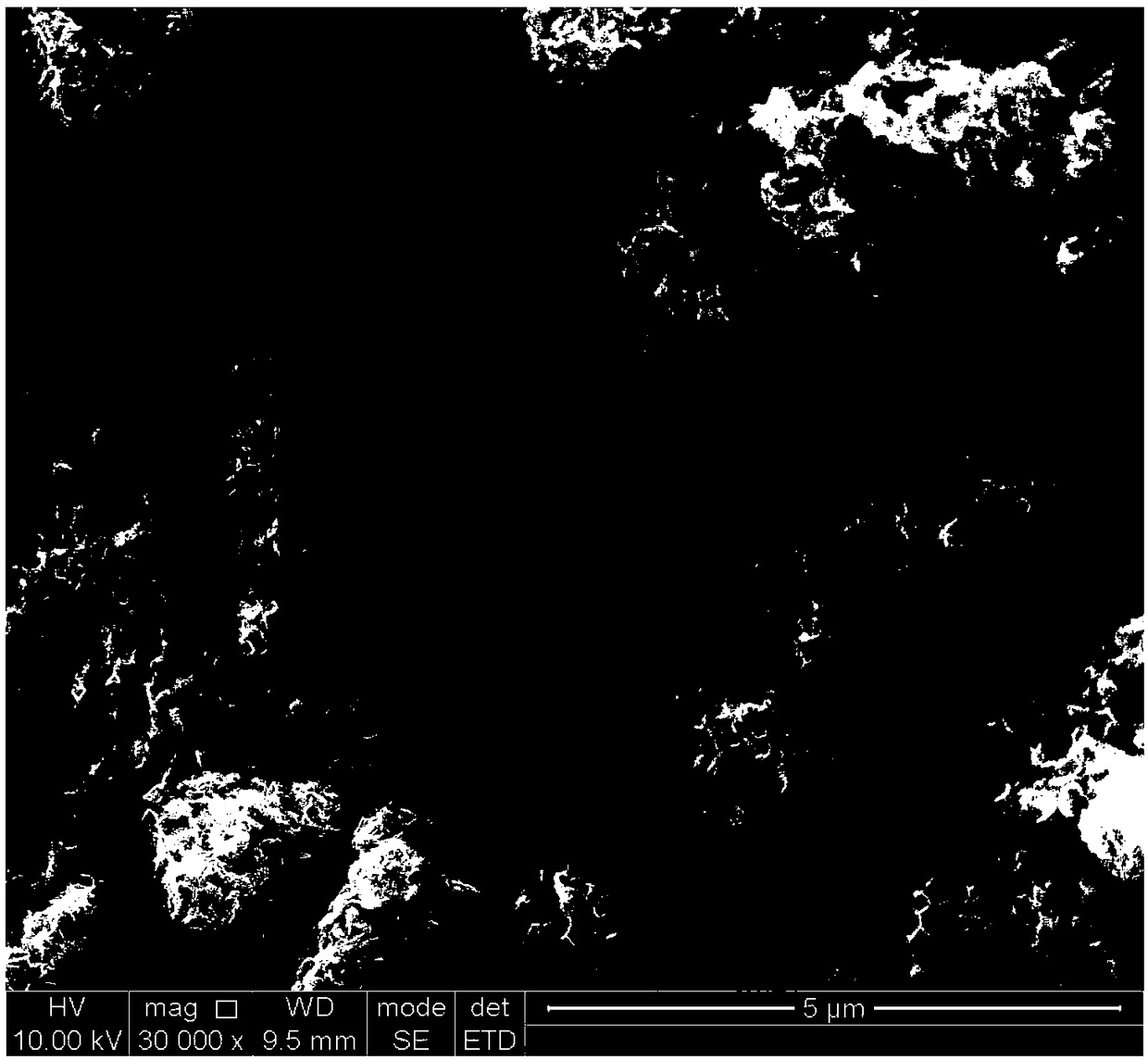

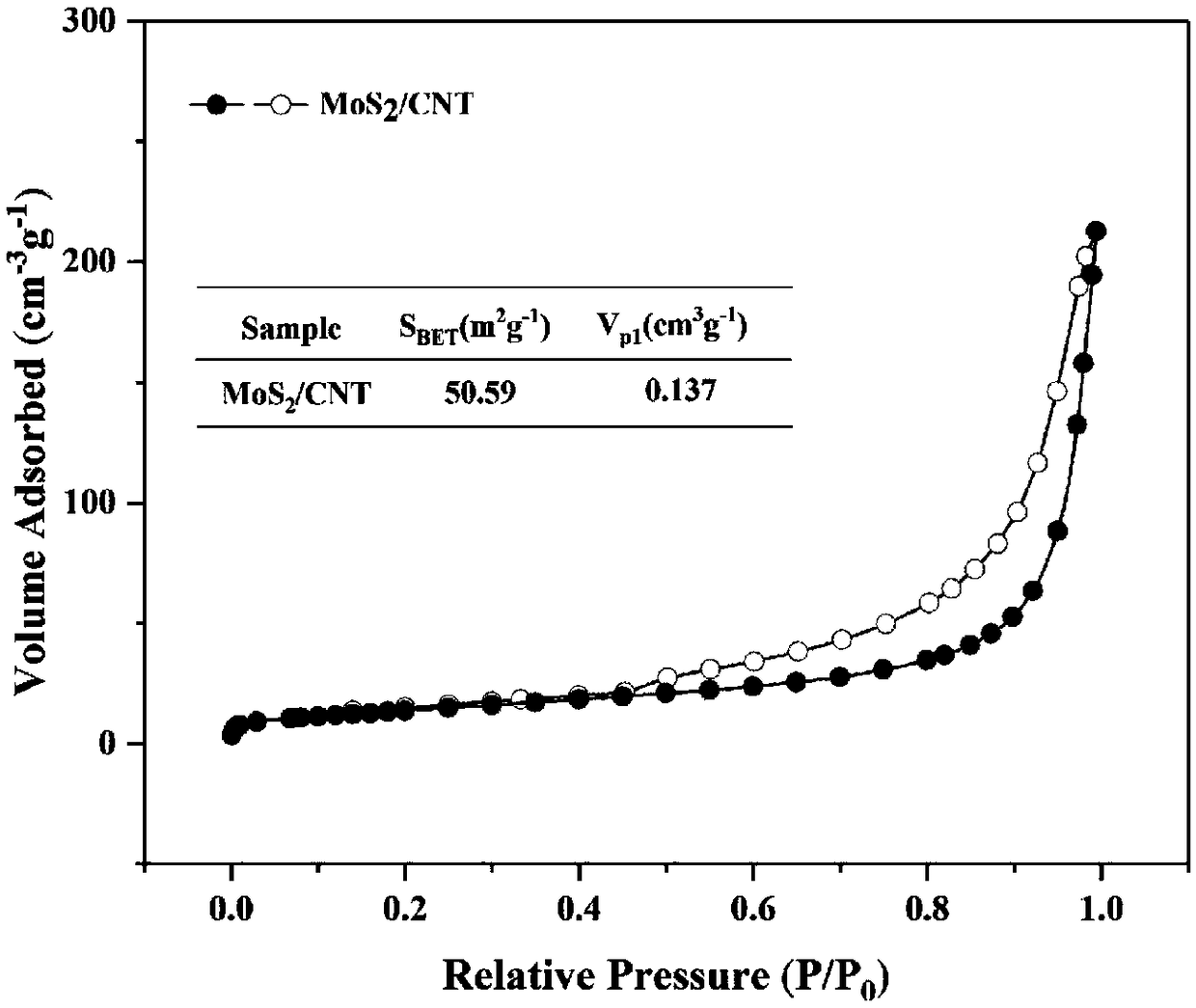

[0030] A preparation method of a three-dimensional interconnected mixed network structure, the carbon nanotube / sodium dodecylbenzenesulfonate mixed solution, sodium molybdate and thiourea are subjected to hydrothermal reaction, filtered, washed, and dried, wherein the carbon nanotube Surface functionalized.

[0031] The surface functionalization of carbon nanotubes specifically includes adding carbon nanotubes into a mixed solution of sulfuric acid and nitric acid for ultrasonic treatment, heating, suction filtering, washing, and vacuum drying overnight to obtain surface functionalized carbon nanotubes.

Embodiment 1

[0033] Surface functionalization of carbon nanotubes (CNTs):

[0034] Add 1gCNTs to 80mlH 2 SO 4 and HNO 3 After ultrasonication in the mixed solution for 10 min, heating in an oil bath at 80°C for 2h, suction filtration, washing with deionized water, and drying in a vacuum oven at 60°C overnight to obtain treated CNTs for use.

[0035] MoS 2 Synthesis of / CNT:

[0036] 1) Disperse 200 mg of surface-functionalized CNTs in 1000 ml of sodium dodecylbenzenesulfonate (SDBS) solution (0.2% w / w), sonicate for 1 h, and use it as a carbon source for later use.

[0037] 2) Mix and stir 151mg sodium molybdate and 200mg thiourea for 1 hour until there is no obvious precipitation, then sonicate the solution for 30 minutes, then add 25ml of CNTs dispersion and 45ml of deionized water to the mixed solution, and continue to sonicate for 30 minutes.

[0038] 3) The homogeneous solution was then transferred to a reaction kettle and heated at 220° C. for 24 hours. The black suspension was...

Embodiment 2

[0041] Surface functionalization of carbon nanotubes (CNTs):

[0042] Add 1gCNTs to 80mlH 2 SO 4 and HNO 3 After ultrasonication in the mixed solution for 10 min, heating in an oil bath at 60°C for 1.5 h, suction filtration, washing with deionized water, and drying in a vacuum oven at 60°C overnight to obtain treated CNTs for use.

[0043] MoS 2 Synthesis of / CNT:

[0044] 1) Disperse 200 mg of surface-functionalized CNTs in 1000 ml of sodium dodecylbenzenesulfonate (SDBS) solution (0.2% w / w), sonicate for 1.5 h, and use it as a carbon source for later use.

[0045] 2) Mix and stir 151mg sodium molybdate and 200mg thiourea for 1 hour until there is no obvious precipitation, then sonicate the solution for 30 minutes, then add 25ml of CNTs dispersion and 45ml of deionized water to the mixed solution, and continue to sonicate for 30 minutes.

[0046] 3) The homogeneous solution was then transferred to a reaction kettle and heated at 220° C. for 24 hours. The black suspensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com