Three-phase magnetorheological fluid and preparation method thereof

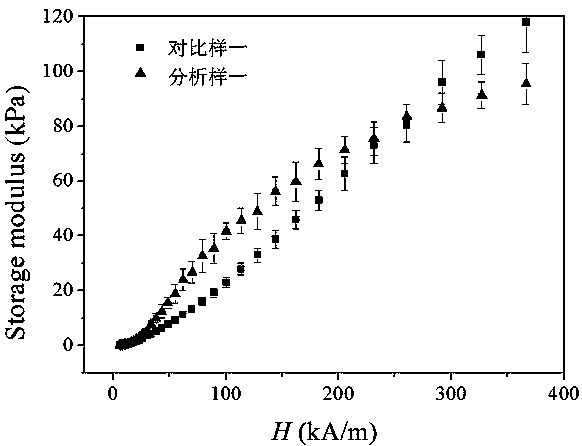

A magnetorheological fluid and three-phase technology, applied in the direction of magnetic fluids, magnetic materials, magnetic objects, etc., can solve the problem of increasing the quality and size of magnetorheological devices, increasing the power load of magnetorheological devices, Increased field viscosity and other issues to achieve the effect of improving magnetic permeability, improving mechanical properties and enhancing magnetorheological effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, a three-phase magnetorheological fluid, is characterized in that: it is composed of the following components by volume percentage:

[0027] Magnetic particles: 5~40%, carrier liquid: 60~90%, magnetic fluid:, emulsifier: 0.05~5%, co-surfactant: 0.03~3%;

[0028] The magnetic particles are carbonyl iron powder or magnetic ferrite powder, and the average particle diameter of the magnetic particles is 1-10 μm.

[0029] The carrier liquid is one or more combinations of water, alcohol, alkane, vegetable oil, mineral oil, silicone oil and polyalphaolefin;

[0030] The magnetic fluid is a water-based magnetic fluid or an oil-based magnetic fluid, including a solvent and magnetic particles with a particle size of 3 to 15 nm ultrasonically dispersed in the solvent, and the magnetic particles are g-Fe 2 o 3 , Fe 3 o 4 Or iron-cobalt-nickel alloy nanoparticles, the volume percentage in the magnetic fluid is 0.1~2%.

[0031] When the magnetic fluid is water-based ...

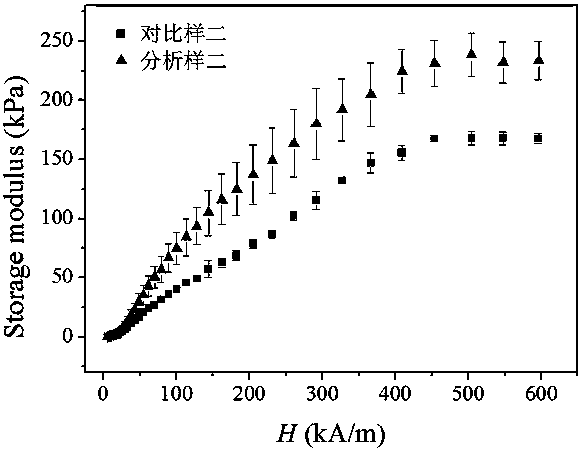

Embodiment 2

[0033] Embodiment two, a kind of preparation method of three-phase magnetorheological fluid, it comprises the following steps:

[0034] 1) Take 0.78g of carbonyl iron powder and dry it for 15 hours under the conditions of vacuum degree of 0.1MPa and temperature of 90°C to remove the physically adsorbed water on the surface of carbonyl iron powder;

[0035] 2) Prepare ferrofluid and prepare Fe by chemical co-precipitation method 3 o 4 Magnetic particles, the specific steps are;

[0036] a. Mix the ferrous salt and the ferric salt in a certain proportion, add the precipitant ammonia solution and stir, and react for a period of time to obtain black Fe 3 o 4 Colloidal particle precipitation, the reaction formula is:

[0037] 2FeCl 3 ·6H 2 O+FeCl 2 4H 2 O+8NH 3 ·H 2 O=Fe 3 o 4 +8NH 4 Cl+24H 2 O;

[0038] b. After washing and separating the black precipitate with water, add HNO 3 The solution was stirred, then Fe(NO 3 ) 3 The solution is boiled and g-Fe is obtained...

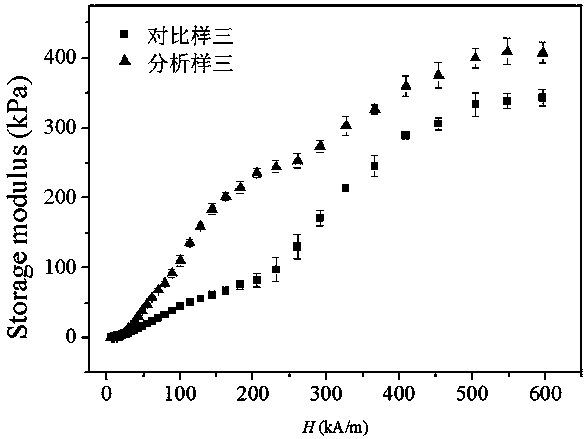

Embodiment 3

[0044] Embodiment three, a kind of preparation method of three-phase magnetorheological fluid, it comprises the following steps:

[0045] 1) Take 1.56g of carbonyl iron powder and dry it for 15 hours under the conditions of vacuum degree of 0.1MPa and temperature of 90°C to remove the physically adsorbed water on the surface of carbonyl iron powder;

[0046] 2) Prepare ferrofluid and prepare Fe by chemical co-precipitation method 3 o 4 Magnetic particles, the specific steps are;

[0047] a. Mix the ferrous salt and the ferric salt in a certain proportion, add the precipitant ammonia solution and stir, and react for a period of time to obtain black Fe 3 o 4 Colloidal particle precipitation, the reaction formula is:

[0048] 2FeCl 3 ·6H 2 O+FeCl 2 4H 2 O+8NH 3 ·H 2 O=Fe 3 o 4 +8NH 4 Cl+24H 2 O;

[0049] b. After washing and separating the black precipitate with water, add HNO 3 The solution was stirred, then Fe(NO 3 ) 3 The solution is boiled and g-Fe is obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com