Al2O3/TiO2 precursor composite thermal spraying powder and preparation method thereof

A technology for thermal spraying powder and precursor, applied in the field of new Al2O3/TiO2 precursor composite thermal spraying powder and its preparation, can solve the problems of inability to obtain uniform powder, poor powder uniformity, poor fluidity, etc. Micro-hardness, good uniformity, uniform and pure product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

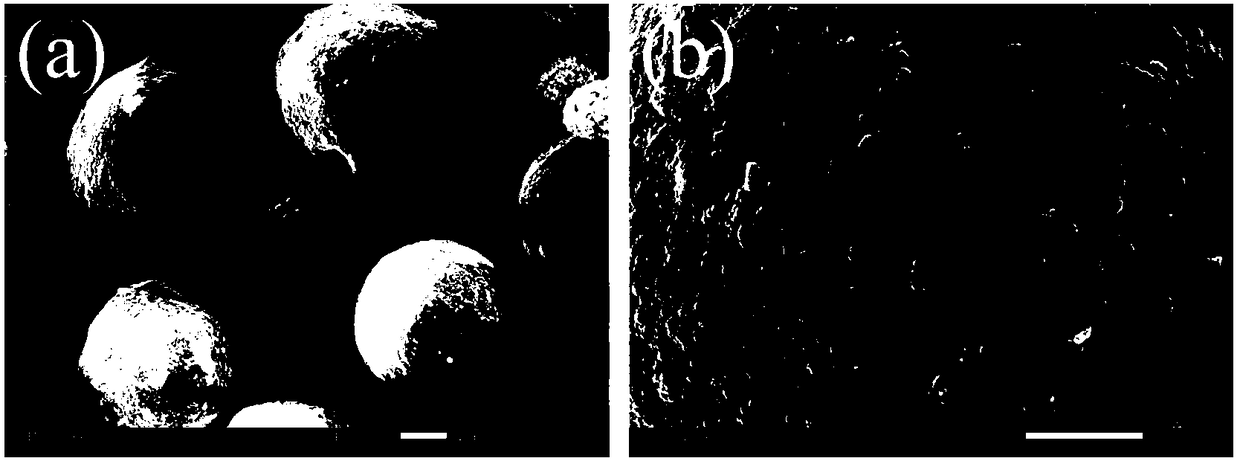

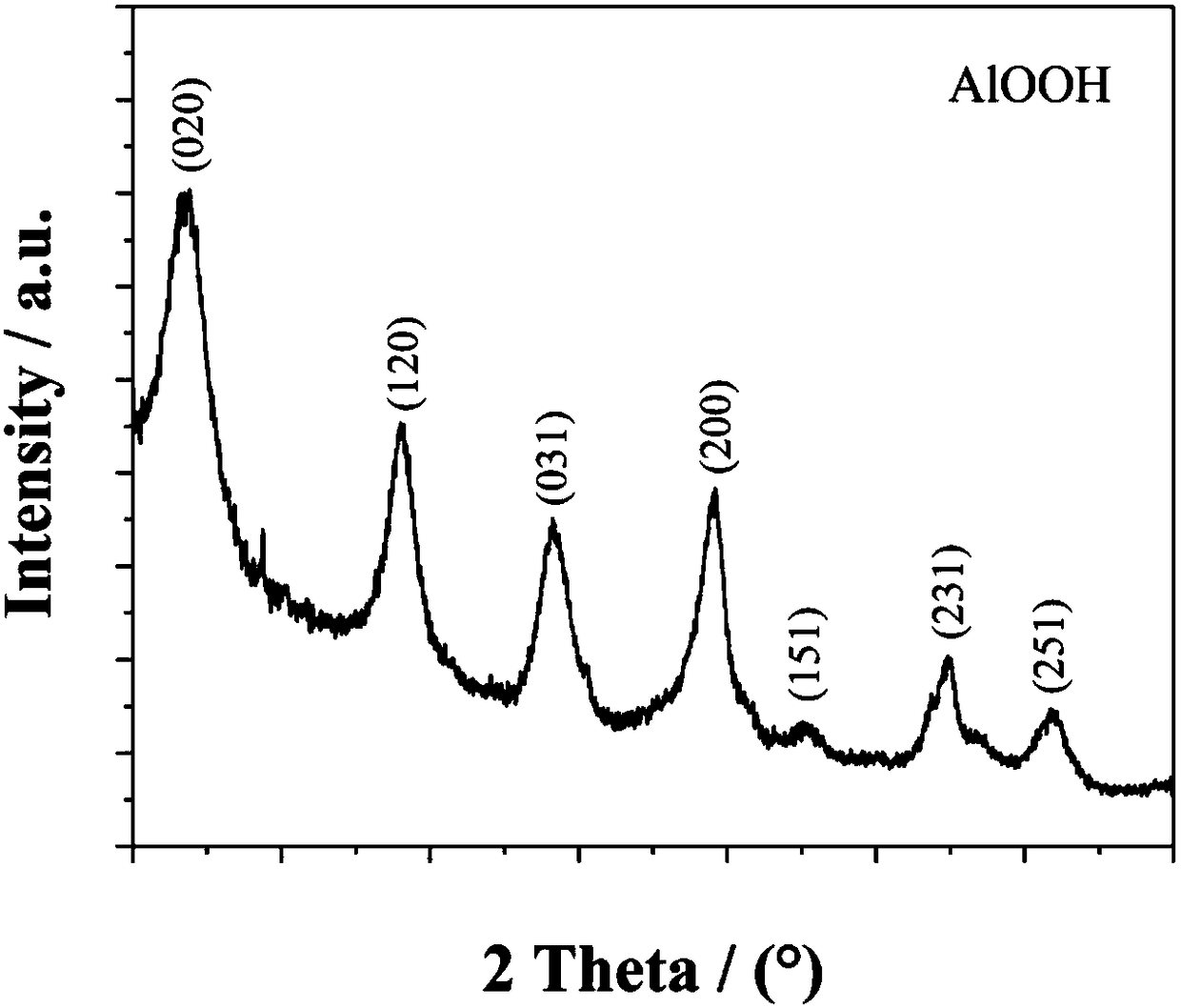

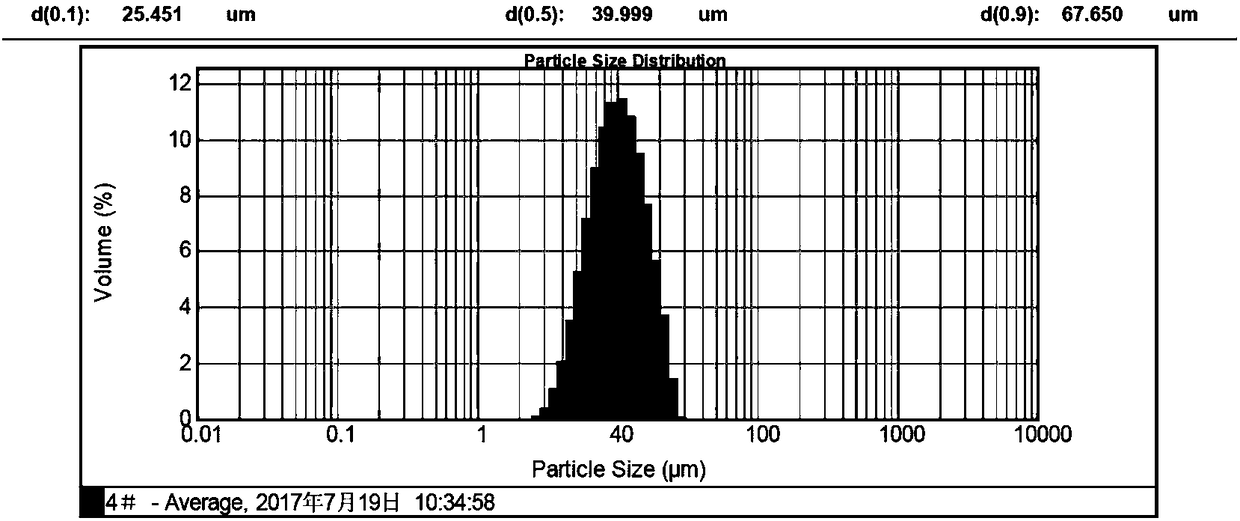

Image

Examples

Embodiment 1

[0030] A new type of Al 2 o 3 / TiO 2 The preparation method of precursor composite thermal spraying powder comprises the steps:

[0031] (1) Weigh 1535.3g of absolute ethanol and 460.6g of deionized water, and use a magnetic stirrer to prepare a mixed solution; after weighing 174g of aluminum isopropoxide, slowly add it to the above mixed solution in a water bath at 90°C, Until the organic salt is completely dissolved and the solution is clear; configure 0.1mol / L dilute nitric acid solution, and slowly add it to the salt solution until the pH value of the solution is 5.5; continue to open and stir for 3 hours to evaporate the hydrolyzate, then condense and reflux for 12 hours, the alumina sol precursor obtained after natural cooling;

[0032] (2) Weigh 121.875g of absolute ethanol and 13.8125g of tetrabutyl titanate, slowly add tetrabutyl titanate into ethanol, shake evenly and put it into a separatory funnel; take the above-mentioned alumina sol precursor, and 1000r·min ...

Embodiment 2

[0037] A new type of Al 2 o 3 / TiO 2 The preparation method of precursor composite thermal spraying powder comprises the steps:

[0038] (1) Weigh 1535.3g of absolute ethanol and 460.6g of deionized water, and use a magnetic stirrer to prepare a mixed solution; after weighing 174g of aluminum isopropoxide, slowly add it to the above mixed solution in a 70°C water bath, Until the organic salt is completely dissolved and the solution is clear; configure 0.1mol / L dilute nitric acid solution, and slowly add it to the salt solution until the pH value of the solution is 5.5; continue to open and stir for 3 hours to evaporate the hydrolyzate, then condense and reflux for 12 hours, the alumina sol precursor obtained after natural cooling;

[0039] (2) Weigh 121.875g of absolute ethanol and 13.8125g of tetrabutyl titanate, slowly add tetrabutyl titanate into ethanol, shake evenly and put it into a separatory funnel; take the above-mentioned alumina sol precursor, and 1000r·min -1 ...

Embodiment 3

[0044] A new type of Al 2 o 3 / TiO 2 The preparation method of precursor composite thermal spraying powder comprises the steps:

[0045] (1) Weigh 1535.3g of absolute ethanol and 460.6g of deionized water, and use a magnetic stirrer to prepare a mixed solution; after weighing 174g of aluminum isopropoxide, slowly add it to the above mixed solution in a water bath at 90°C, Until the organic salt is completely dissolved and the solution is clear; configure 0.1mol / L dilute nitric acid solution, and slowly add it to the salt solution until the pH value of the solution is 4.5; continue to open and stir for 3 hours to evaporate the hydrolyzate, then condense and reflux for 12 hours, the alumina sol precursor obtained after natural cooling;

[0046] (2) Weigh 121.875g of absolute ethanol and 13.8125g of tetrabutyl titanate, slowly add tetrabutyl titanate into ethanol, shake evenly and put it into a separatory funnel; take the above-mentioned alumina sol precursor, and 1000r·min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com