A water-resistant machine-sprayed gypsum-based material and its preparation method

A gypsum-based, raw material technology, applied in the field of building materials, can solve the problems of large curing shrinkage, damage to the coating layer, and reduced strength, and achieve the effects of reducing porosity, increasing density, and improving waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

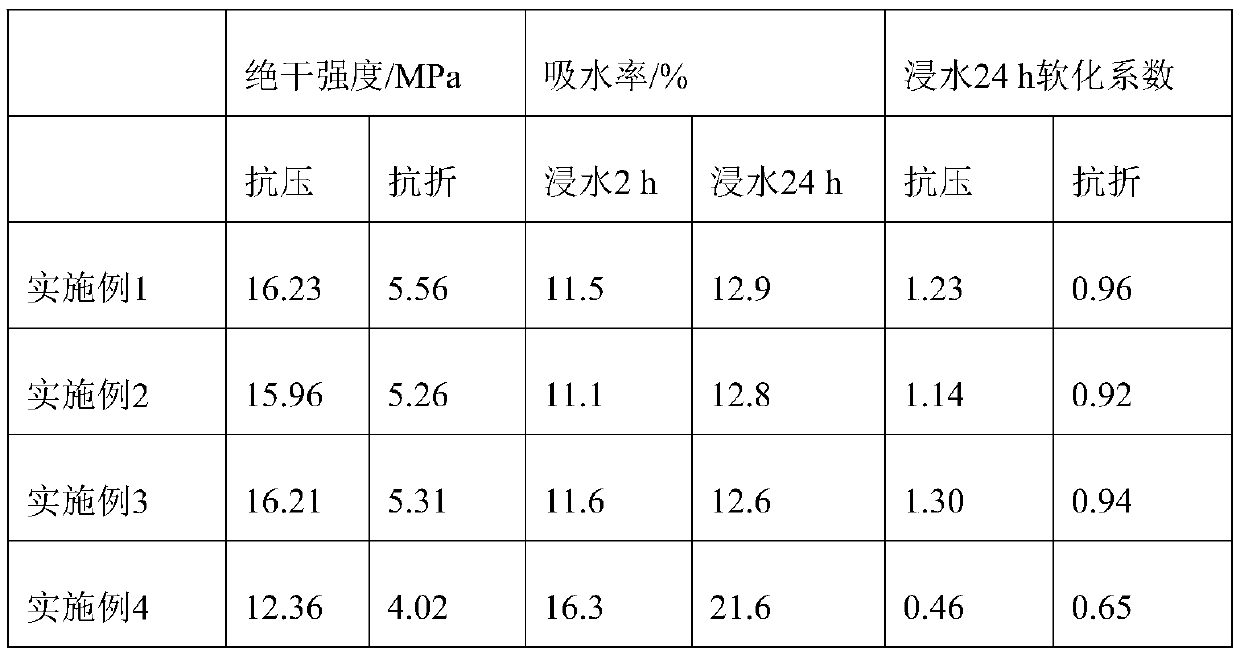

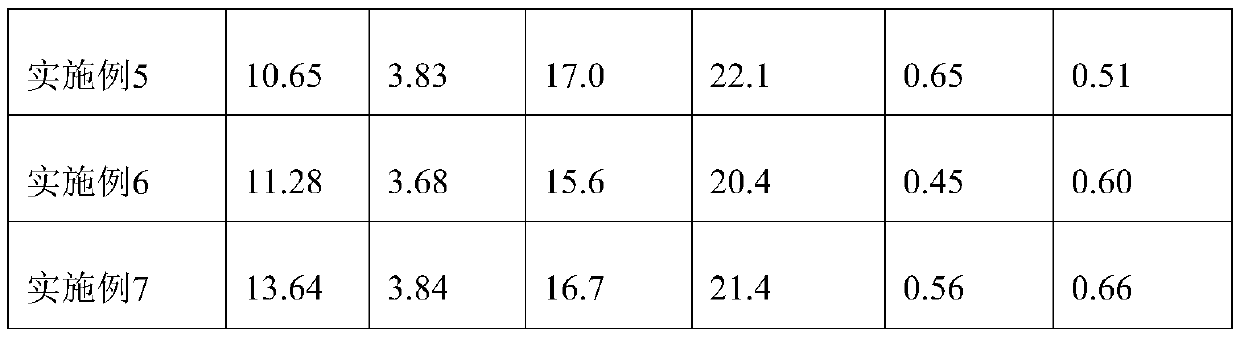

Examples

Embodiment 1

[0045] A water-resistant machine-sprayed gypsum-based material, prepared from the following raw materials in parts by weight: 60kg of gypsum, 10kg of Portland cement or calcium hydroxide, 2kg of lightweight aggregate, 0.5kg of additives, 0.3kg of modified cellulose ether, Composite retarder 0.02kg, thixotropic lubricant 0.3kg, dispersible rubber powder 0.7kg, water repellent 0.5kg.

[0046] The lightweight aggregate is a medium-quality mixture of vitrified microbeads, vermiculite, ceramsite, expanded perlite and polystyrene particles.

[0047] The additive is formed by mixing calcium sulfate, calcium carbide, plant fiber rice husk powder, and corn starch in a mass ratio of 0.5:0.5:0.2:0.3.

[0048] The corn starch includes the following preparation steps: mixing corn starch and lye at a mass ratio of 2:5, stirring at 30°C for 2h, treating at 121°C and 1.4MPa for 1min, drying at low temperature, and pulverizing.

[0049] The lye is 1% sodium bicarbonate solution in mass fracti...

Embodiment 2

[0066] A water-resistant machine-sprayed gypsum-based material, prepared from the following raw materials in parts by weight: 80kg of gypsum, 15kg of Portland cement or calcium hydroxide, 6kg of lightweight aggregate, 0.7kg of additives, 0.3kg of modified cellulose ether, Composite retarder 0.02kg, thixotropic lubricant 0.3kg, dispersible rubber powder 0.7kg, water repellent 0.5kg.

[0067] The lightweight aggregate is vitrified microbeads.

[0068] The additive is prepared by mixing calcium sulfate, calcium carbide, plant fiber rice husk powder, and corn starch in a mass ratio of 0.7:0.7:0.25:0.4.

[0069] The corn starch includes the following preparation steps: mixing corn starch and lye at a mass ratio of 2.3:6, stirring at 33°C for 2.3h, treating at 121°C and 1.5MPa for 2min, drying at low temperature, and pulverizing.

[0070] The lye is a sodium bicarbonate solution with a mass fraction of 1.2%.

[0071] The water-repellent agent is composed of the following raw mater...

Embodiment 3

[0087] A water-resistant machine-sprayed gypsum-based material, prepared from the following raw materials in parts by weight: gypsum 90kg, Portland cement or calcium hydroxide 20kg, lightweight aggregate 10kg, additive 1kg, modified cellulose ether 0.3kg, compound 0.02kg retarder, 0.3kg thixotropic lubricant, 0.7kg dispersible rubber powder, 0.5kg water repellent.

[0088] The lightweight aggregate is a mixture of vermiculite and ceramsite.

[0089] The additive is calcium sulfate, calcium carbide, plant fiber rice husk powder, and corn starch mixed in a mass ratio of 1:1:0.3:0.6.

[0090] The corn starch includes the following preparation steps: mixing corn starch and lye in a mass ratio of 3:7, stirring at 35°C for 3h, treating at 121°C and 1.8MPa for 3min, drying at low temperature, and pulverizing.

[0091] The lye is 2% sodium bicarbonate solution in mass fraction.

[0092] The water-repellent agent is composed of the following raw materials in parts by mass, silicone s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drying shrinkage | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com