Lanthanide fluoride two-dimensional porous nanosheet as well as preparation method and application thereof

A lanthanide and fluoride technology, which is applied in the field of lanthanide fluoride two-dimensional porous nanosheets and their preparation, can solve the problems of cumbersome post-processing steps, difficulty in realizing large-scale preparation of two-dimensional materials, etc., so as to avoid pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a two-dimensional porous nanosheet of lanthanide fluoride, comprising the following steps:

[0025] (1) In a nitrogen atmosphere, the water-soluble lanthanide metal salt lanthanide salt and sodium acetate aqueous solution are mixed to obtain a mixed solution;

[0026] (2) adding an aqueous fluorine-containing salt solution to the mixed solution obtained in the step (1) to undergo a precipitation reaction to obtain a two-dimensional porous nanosheet of lanthanide fluoride.

[0027] The present invention mixes water-soluble lanthanide metal salts and sodium acetate aqueous solution in a nitrogen atmosphere to obtain a mixed liquid. In the present invention, it is preferred to firstly add water into the reaction device, and then pass nitrogen to remove air.

[0028] In the present invention, the water-soluble lanthanide metal salt preferably includes one or more of nitrates, chlorates, chlorides and acetates of lanthanides, mo...

Embodiment 1

[0047] Take pure water (300mL) into a three-necked flask, and after bubbling nitrogen gas for 20min, add 3.6mmol of cerium nitrate and 3.6mmol of sodium acetate solid powder in turn, wherein the molar ratio of cerium nitrate and sodium acetate is 1:1, after stirring and dissolving Add 20mL, 5mg / mL ammonium fluoride aqueous solution to the aqueous solution containing cerium nitrate, keep stirring for 2h, and finally centrifuge and freeze-dry to obtain cerium fluoride (F-Ce) two-dimensional porous nanosheets.

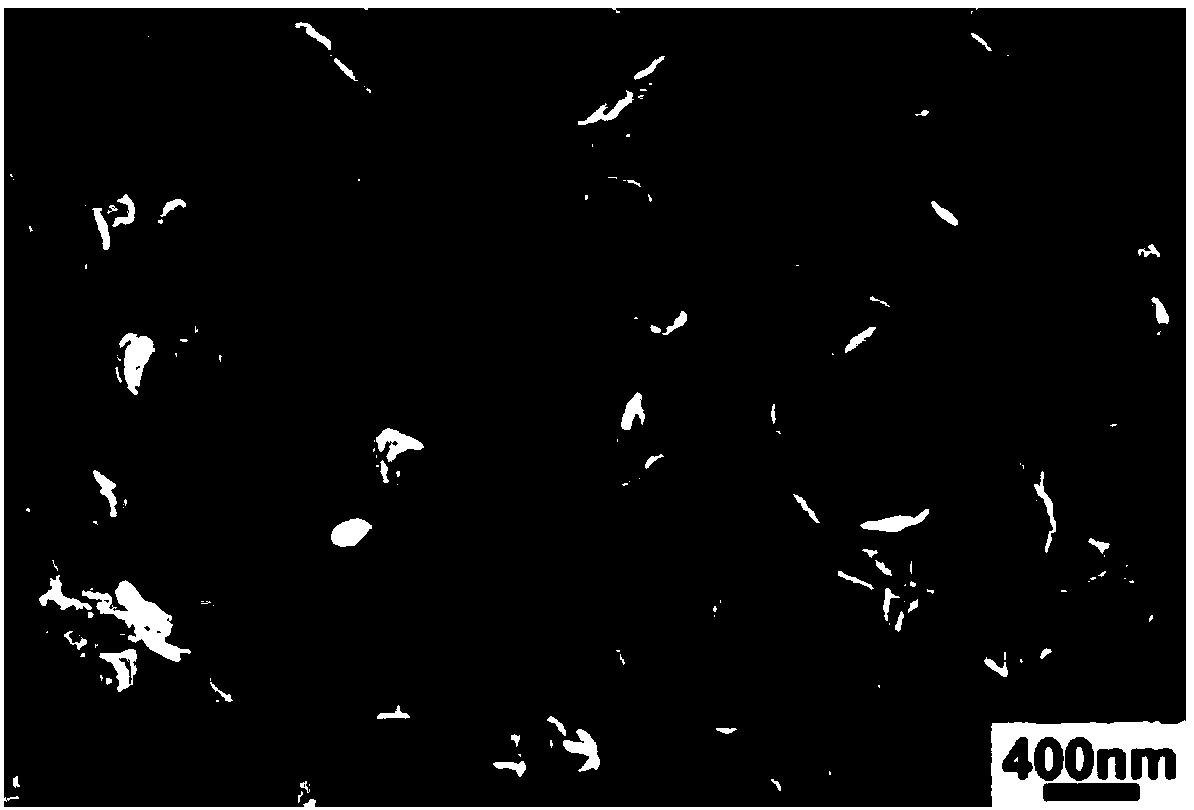

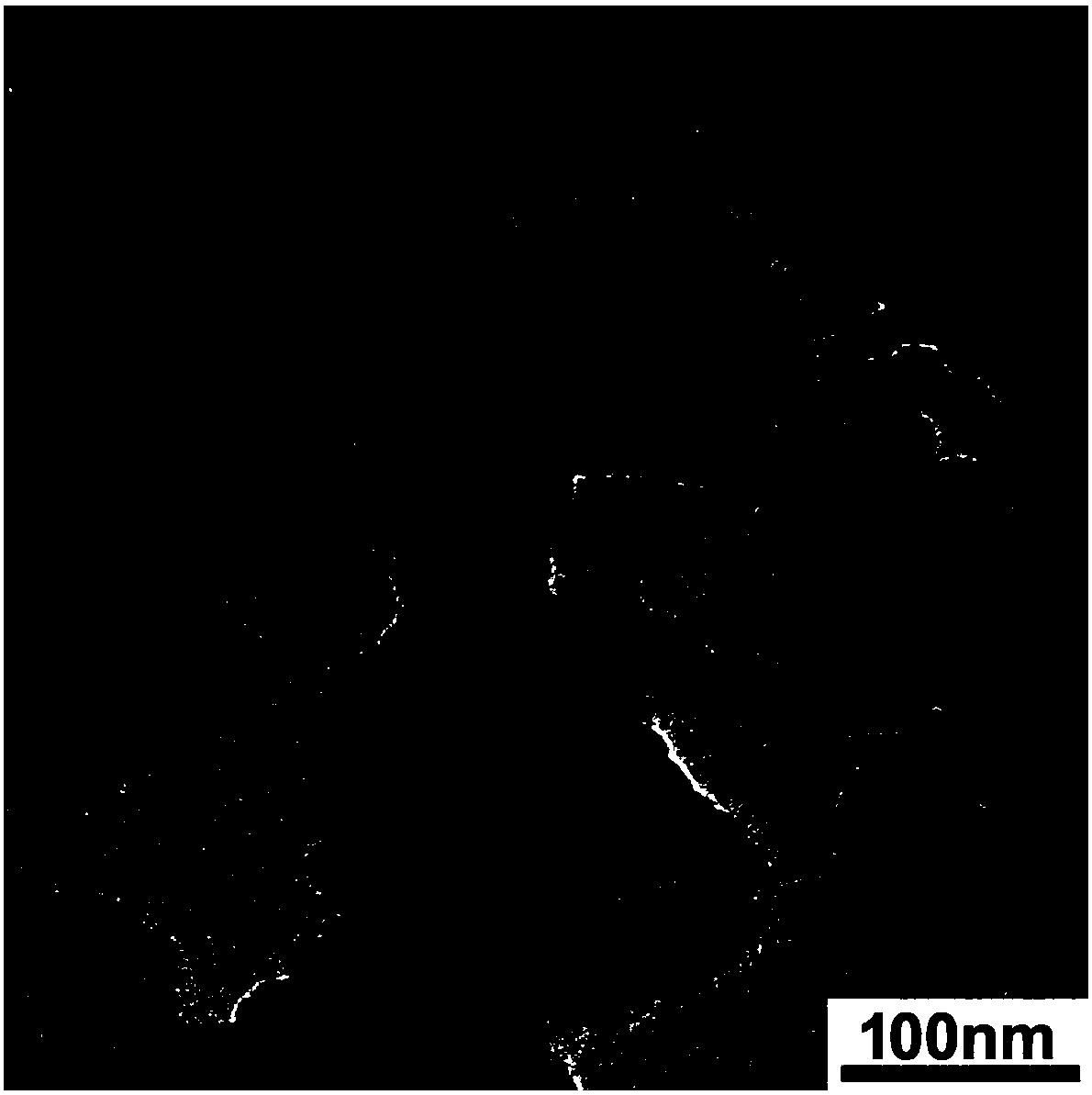

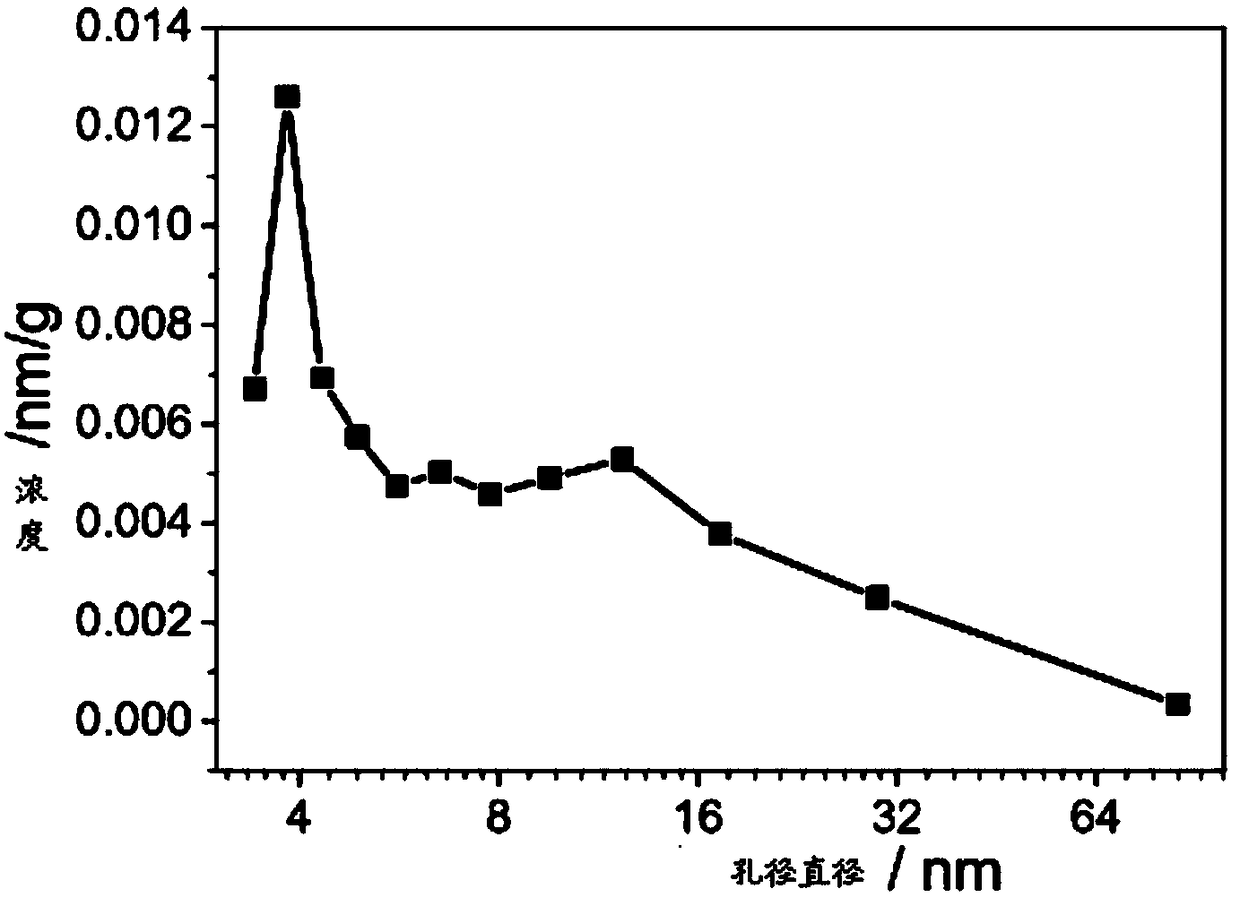

[0048] The field emission electron micrograph of the cerium fluoride (F-Ce) two-dimensional porous nanosheet that makes in the present embodiment is as follows figure 1 As shown in the figure, it can be clearly observed that a large number of two-dimensional nanosheets are stacked together; figure 2 The transmission electron micrograph in the photo confirms again that the product that makes in the present embodiment is cerium fluoride (F-Ce) two-dimensional nanosheet; Ca...

Embodiment 2

[0051] Take 200mL of pure water into a three-necked flask, and after bubbling nitrogen gas for 30min, add 1.2mmol of cerium acetate and 3.6mmol of sodium acetate solid powder in turn, wherein the molar ratio of cerium acetate and sodium acetate is 1:3, and dissolve 50mL of 10 mg / mL sodium fluoride solution was added to the aqueous solution containing cerium acetate, and kept stirring for 4 hours, and finally centrifuged and freeze-dried to obtain cerium fluoride (F-Ce) two-dimensional porous nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com