Preparation method of hydroxymethylated lignin

A technology of hydroxymethylation and lignin, which is applied in the field of preparation of hydroxymethylated lignin, can solve the limitation of large-scale industrial production of hydroxymethylated lignin and the improvement of yield, generation of a large amount of waste liquid, complicated treatment, etc. problems, to save the steps of product post-processing, reduce the amount of waste liquid, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

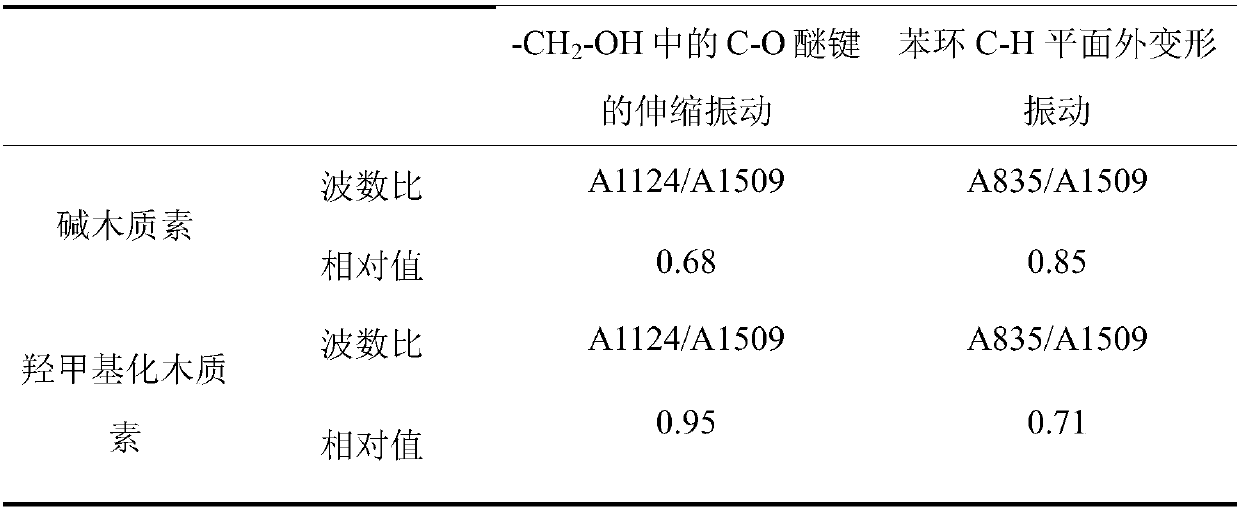

Embodiment 1

[0025] Add 12g of wheatgrass lignin, 0.12g of NaOH solid, and 3.0g of 37% formaldehyde solution into the hydrothermal reaction kettle, stir evenly, seal the reaction kettle, then raise the temperature to 80°C, keep it warm for 60min, cool to room temperature, and wash the product , suction filtration, and drying to obtain hydroxymethylated lignin. The yield of hydroxymethylated lignin obtained in this example was 68%.

Embodiment 2

[0027] Add 12g of wheatgrass lignin, 0.42g of NaOH solid, and 3.0g of 37% formaldehyde solution into the hydrothermal reaction kettle, stir evenly, seal the reaction kettle, then raise the temperature to 80°C, keep it warm for 120min, cool to room temperature, and wash the product , suction filtration, and drying to obtain hydroxymethylated lignin. The yield of hydroxymethylated lignin obtained in this example was 70%.

Embodiment 3

[0029] Add 12g of wheatgrass lignin, 0.42g of NaOH solid, and 3.0g of 37% formaldehyde solution into the lining of the hydrothermal reaction kettle, stir evenly, seal the reaction kettle, then raise the temperature to 100°C, keep the temperature for 120min, cool to room temperature, and test the product Washing, suction filtration, and drying to obtain hydroxymethylated lignin. The yield of hydroxymethylated lignin obtained in this example was 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com