Pineapple residue hemicellulose-based pH-sensitive porous hydrogel and its preparation method and application

A porous hydrogel and hemicellulose technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of aggravated environmental pollution and waste of resources, and achieve low price, low equipment requirements, and simple process routes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

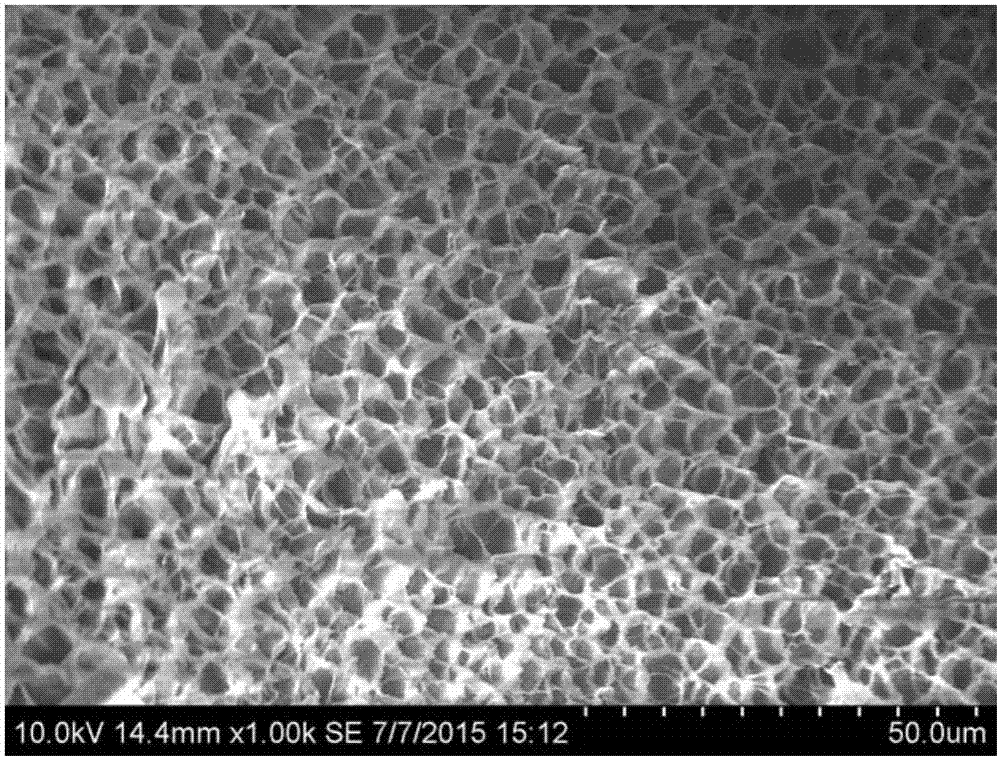

Image

Examples

Embodiment 1

[0032] A preparation method of pineapple residue hemicellulose-based pH-sensitive porous hydrogel, specifically comprising the following steps:

[0033] (1) After the pineapple residue is crushed through 40 meshes, the delignification pretreatment is carried out at 70° C. for 3 h with a mass fraction of 5% sodium chlorite solution, and the mass-to-volume ratio of the pineapple residue to the sodium chlorite solution is 1 g: 15mL, after adding sodium chlorite solution, adjust the pH of the solution to 3.8 with acetic acid to obtain pretreated pineapple pomace;

[0034] (2) The pretreated pineapple residue is extracted using the NaOH aqueous solution graded extraction method, and the graded extraction method is divided into three stages of extraction, the mass concentration of the primary extraction lye is 2%, and the secondary extraction The mass concentration is 5%, the three-stage extraction lye mass concentration is 10%, the mass volume ratio of the pretreated pineapple poma...

Embodiment 2

[0037] A preparation method of pineapple residue hemicellulose-based pH-sensitive porous hydrogel, specifically comprising the following steps:

[0038] (1) After the pineapple residue is crushed through 40 meshes, the delignification pretreatment is carried out at 70° C. for 3 h with a mass fraction of 7.5% sodium chlorite solution, and the mass volume ratio of the pineapple residue to the sodium chlorite solution is 1 g: 20mL, after adding sodium chlorite solution, adjust the pH of the solution to 3.9 with acetic acid to obtain pretreated pineapple pomace;

[0039] (2) The pretreated pineapple residue is extracted using the NaOH aqueous solution graded extraction method, and the graded extraction method is divided into three stages of extraction, the mass concentration of the primary extraction lye is 2%, and the secondary extraction The mass concentration is 5%, the mass concentration of the three-stage extraction lye is 10%, the mass volume ratio of the pretreated pineappl...

Embodiment 3

[0042] A preparation method of pineapple residue hemicellulose-based pH-sensitive porous hydrogel, specifically comprising the following steps:

[0043] (1) After the pineapple residue is crushed through 40 meshes, the delignification pretreatment is carried out at 70° C. for 3 h with a mass fraction of 10% sodium chlorite solution, and the mass-to-volume ratio of the pineapple residue to the sodium chlorite solution is 1 g: 25mL, after adding sodium chlorite solution, adjust the pH of the solution to 4.0 with acetic acid to obtain pretreated pineapple pomace;

[0044] (2) The pretreated pineapple residue is extracted using the NaOH aqueous solution graded extraction method, and the graded extraction method is divided into three stages of extraction, the mass concentration of the primary extraction lye is 2%, and the secondary extraction The mass concentration is 5%, the mass concentration of the three-stage extraction lye is 10%, the mass volume ratio of the pretreated pineappl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com