Acidic waste gas treatment device

A technology for acid waste gas and treatment device, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of large size of waste gas treatment device, high investment and operating costs, and reduce equipment investment and use and maintenance costs. , Small footprint and the effect of reducing the frequency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

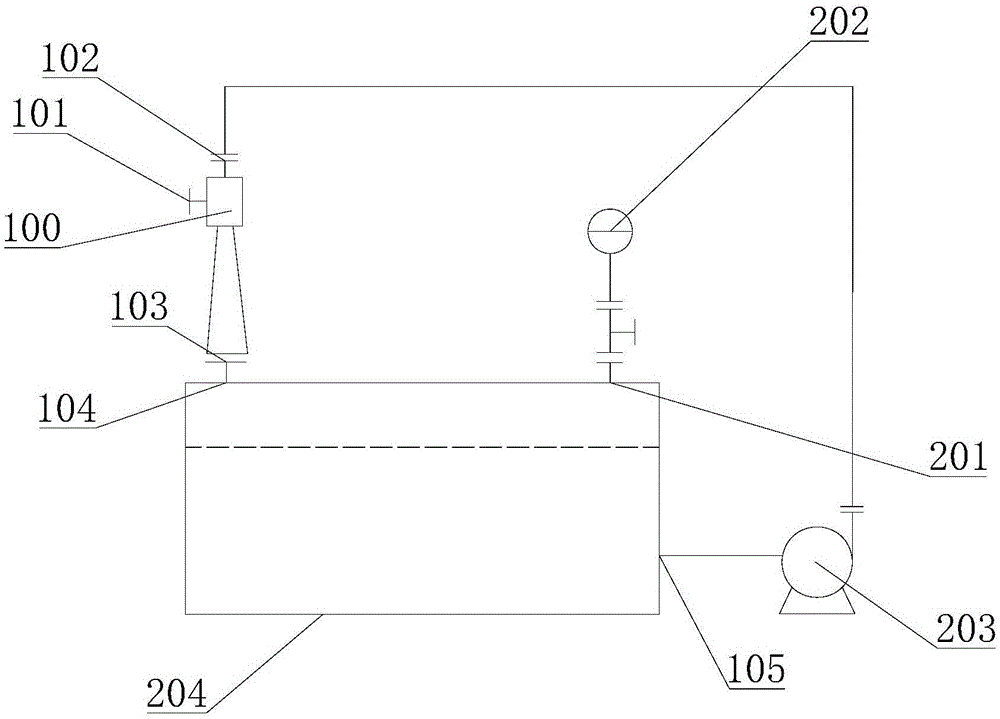

[0032] see figure 1, this embodiment provides an acid waste gas treatment device, including: a liquid storage tank 204 for storing lye, a first gas-liquid mixer for mixing acid waste gas and lye, and a delivery pump for transporting lye 203. Wherein, the first gas-liquid mixer is provided with a first mixing chamber 100, a first liquid inlet 102, a first liquid outlet 103, and a first air inlet 101 for inputting acid waste gas. The first air inlet 101, the first Both the liquid inlet 102 and the first liquid outlet 103 communicate with the first mixing chamber 100 .

[0033] The liquid storage tank 204 is provided with the first output hole 105 and the first input hole 104, the input end of the delivery pump 203 is connected with the first output hole 105, the output end of the delivery pump 203 is connected with the first liquid inlet 102, and the first liquid discharge The port 103 is connected with a first input hole 104 .

[0034] The mixing chamber of the first gas-liq...

Embodiment 2

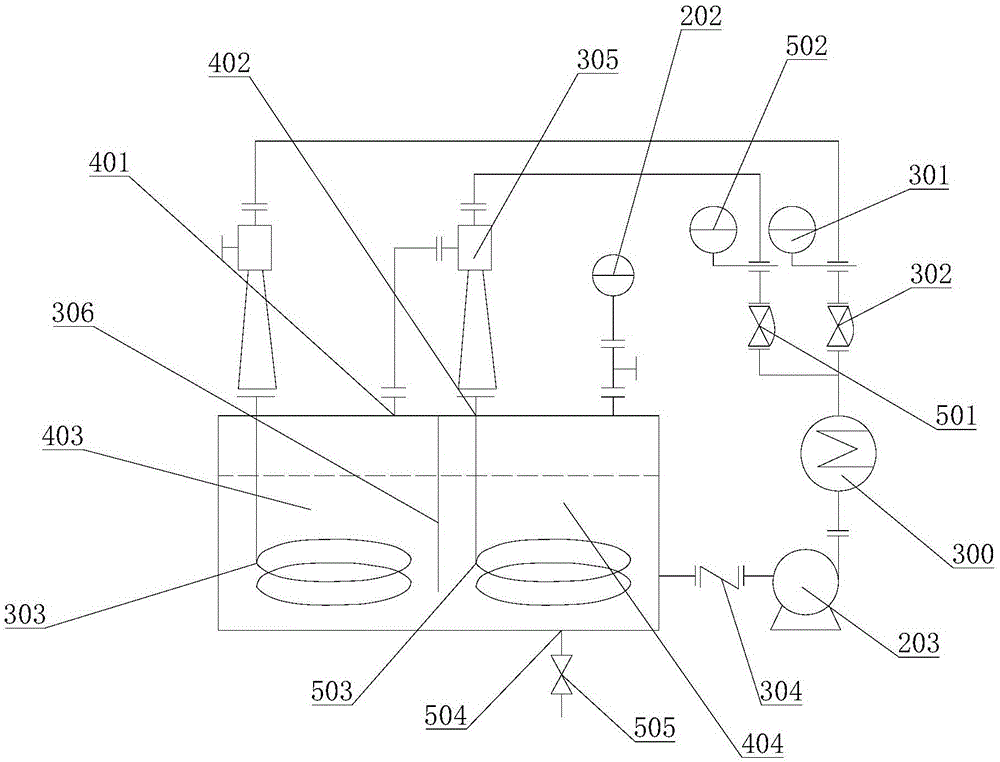

[0039] refer to figure 2 , this embodiment provides an acid waste gas treatment device, including: a liquid storage tank 204 for storing lye, a first gas-liquid mixer for mixing acid waste gas and lye, and a delivery pump for transporting lye 203. Wherein, the first gas-liquid mixer is provided with a first mixing chamber 100, a first liquid inlet 102, a first liquid outlet 103, and a first air inlet 101 for inputting acid waste gas. The first air inlet 101, the first Both the liquid inlet 102 and the first liquid outlet 103 communicate with the first mixing chamber 100 . The liquid storage tank 204 is provided with the first output hole 105 and the first input hole 104, the input end of the delivery pump 203 is connected with the first output hole 105, the output end of the delivery pump 203 is connected with the first liquid inlet 102, and the first liquid discharge The port 103 is connected with a first input hole 104 .

[0040] Because acid-base neutralization will pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com