Polyoxometallate and compound, preparation method and application thereof

A technology of polyoxometalates and complexes, applied in chemical instruments and methods, water treatment of special compounds, water pollutants, etc. Problems such as low utilization of light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Polyoxometalate compounds (NH 4 ) 3 PW 11 O 39 Preparation of Sn:

[0062] Step 1: Weigh ammonium phosphotungstate and stannous chloride in a mass ratio of 1:2, add them into 20 mL of distilled water respectively, and dissolve them ultrasonically to obtain stannous chloride solution and ammonium phosphotungstate dispersion;

[0063]Step 2: Pour the stannous chloride aqueous solution into the ammonium phosphotungstate dispersion liquid and ultrasonically mix evenly to obtain a mixed dispersion liquid;

[0064] Step 3: Adjust the pH of the mixed dispersion to 1.0, place the pH-adjusted mixed solution in a water bath, heat in a water bath at 60°C for 3 hours, cool, filter with suction, and dry at 40°C to obtain polyoxometalates. compound.

Embodiment 2-5

[0066] The polyoxometalate compound (NH 4 ) 3 PW 11 O 39 The preparation method of Sn is the same as that in Example 1, and the specific reaction conditions are shown in Table 1.

[0067] Table 1 embodiment 2-5 reaction conditions

[0068] Example

(NH 4 ) 3 PW 12 O 40 and SnCl 2 mass ratio

pH

2

1:3

1.5

3

1:1

2.0

4

1:2

2.5

5

1:0.5

3.0

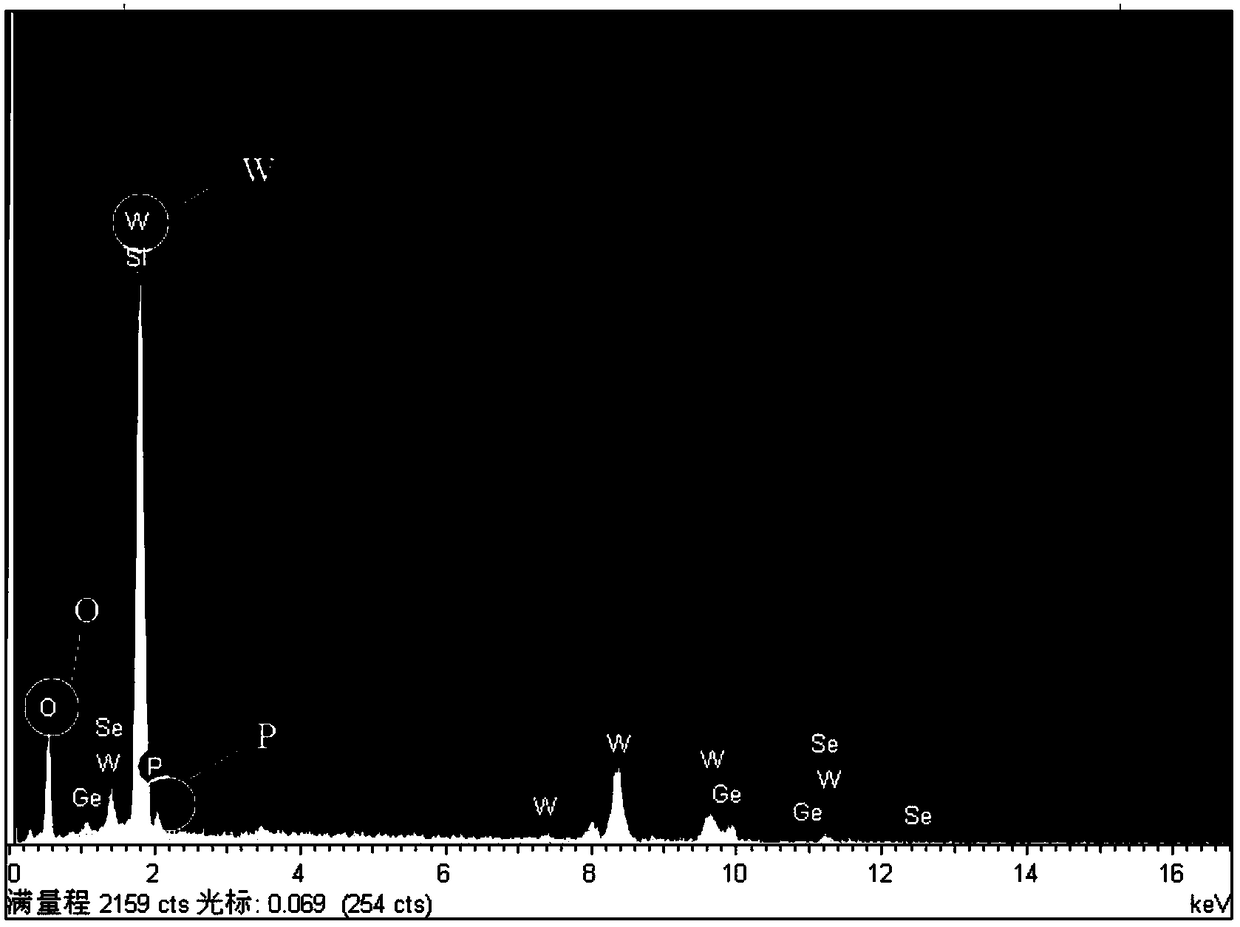

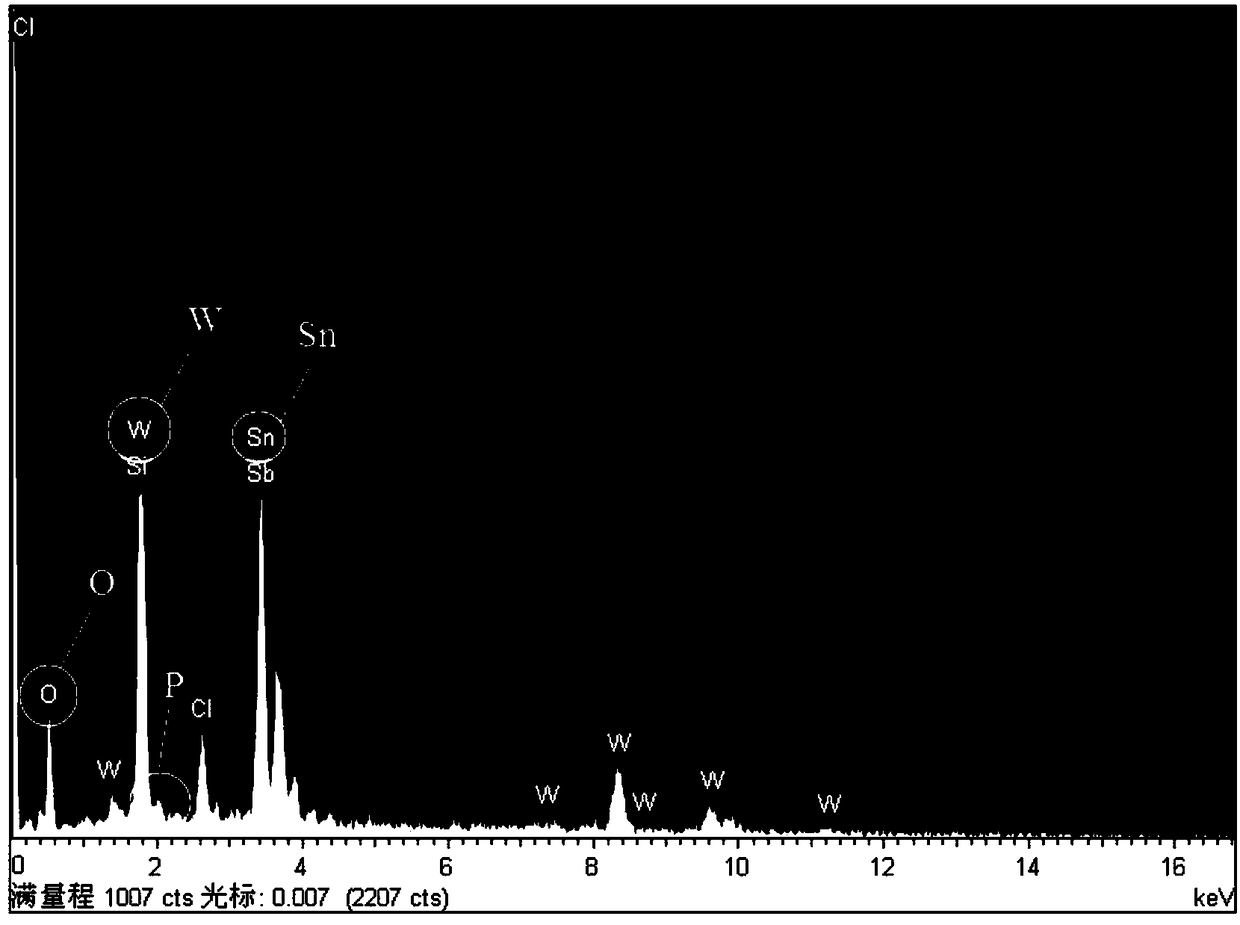

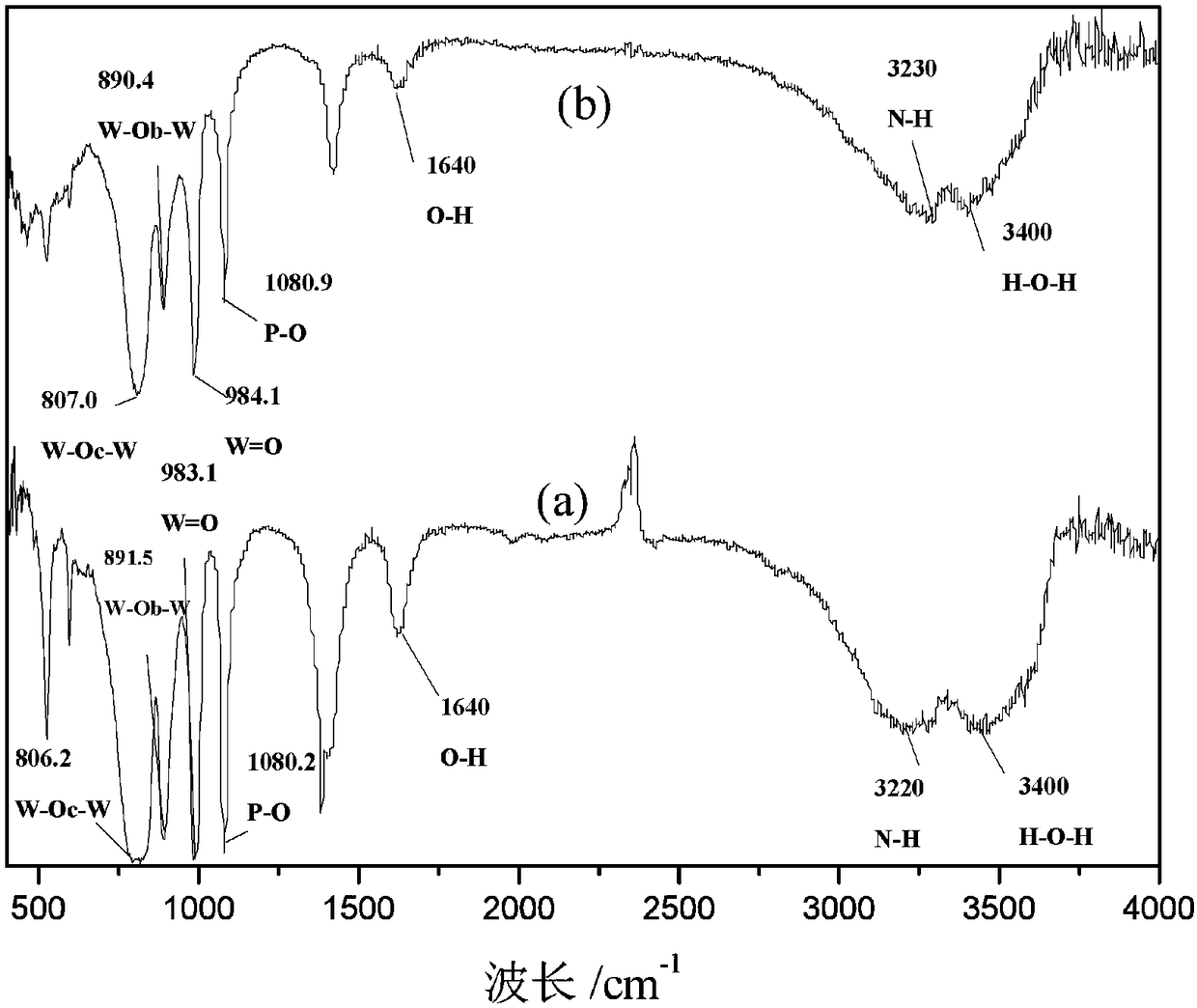

[0069] Taking Example 4 as an example, characterization was carried out, and the characterization results were as follows:

[0070] Scanning electron microscope SEM ( Figure 1a and Figure 1b ), it can be seen that after doping with transition metal tin, the particles become smaller, the particle distribution is uniform, and the particles are fluffy. This fluffy structure is conducive to the contact between the pollutants and the catalyst and improves the photocatalytic activity of the catalyst. Figure 1c and Figure 1d for (NH 4)3 PW 12 O 40 and (NH 4 )...

Embodiment 6

[0094] Complexes of polyoxometalates (NH 4 ) 3 PW 11 O 39 Sn / TiO 2 Preparation of:

[0095] Step a, according to the mass ratio of 1:2, weigh the polyoxometalate and titanium dioxide nanoparticles prepared in Example 4, add in 30 mL of absolute ethanol, dissolve by ultrasonic, polyoxometalate dispersion and titanium dioxide dispersion ;

[0096] Step b. Add the titanium dioxide dispersion into the polyoxometalate dispersion and mix evenly with ultrasonics, mix well, adjust the pH to 1.0, transfer to a water bath at 60°C, heat in a water bath for 3 hours, cool, filter and wash with suction, Dry at 40°C and grind to obtain powder (NH 4 ) 3 PW 11 O 39 Sn / TiO 2 catalyst of light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com