Method for improving alignment of lithography mark, epitaxial layer for alignment of lithography mark, and preparation method for super-junction

A technology of lithographic marking and epitaxial layer, which is applied in the field of preparation of epitaxial layer and super junction, can solve the problems of difficulty in guaranteeing the quality of epitaxial layer, difficult automatic identification of lithography machine, affecting product production efficiency, etc., and achieves the goal of mark alignment and identification Chance Increase, Integrity Preservation, Performance Improvement Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

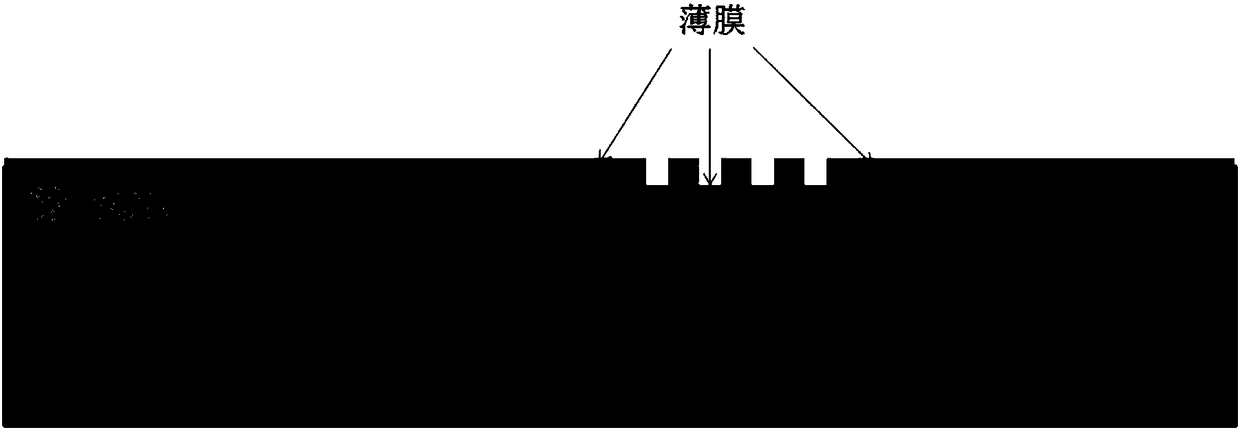

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with examples, but those skilled in the art will understand that the following examples are only for illustrating the present invention, and should not be considered as limiting the scope of the present invention. Those who do not indicate the specific conditions in the examples are carried out according to the conventional conditions or the conditions suggested by the manufacturer. The reagents or instruments used were not indicated by the manufacturer, and they were all conventional products that could be purchased from the market.

[0026] A method for improving alignment of lithography marks, an epitaxial layer for alignment of lithography marks, and a method for preparing a super junction according to an embodiment of the present invention are described in detail below:

[0027] It is well known that when doping and epitaxial operations are performed on the chip in the radial dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com