Method and system for treating slag-containing coal tar

A coal tar, oil and gas technology, which is applied in the field of processing slag-containing coal tar and the system field of processing slag-containing coal tar, can solve the problems of unfavorable coal tar processing and utilization, excessive waste water, high corrosion resistance requirements of equipment and pipelines, and achieve improvement Effects of utilization rate, quality improvement and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

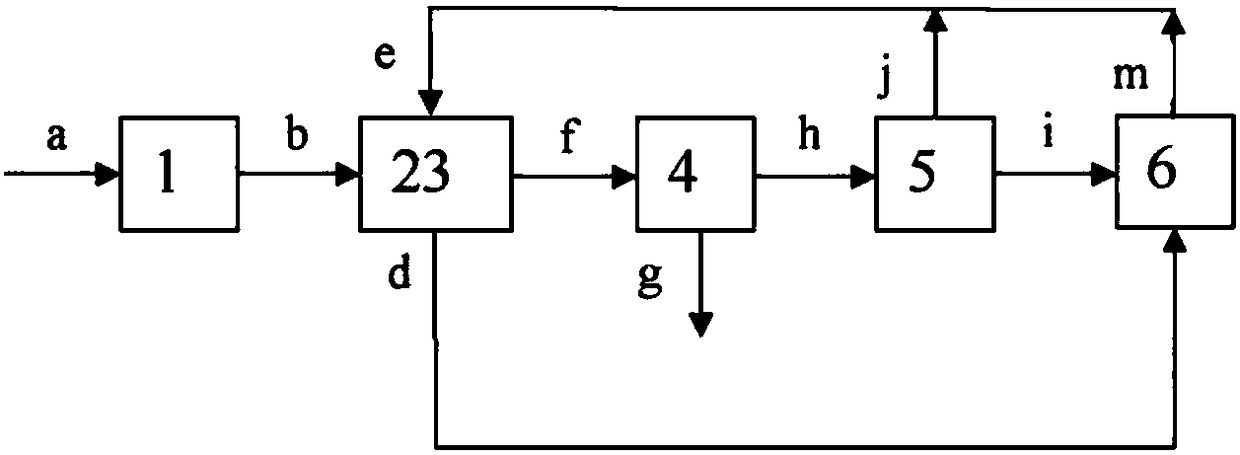

[0085] figure 1 A flowchart of a first exemplary embodiment of the present invention is shown. Pulverized coal a enters the pyrolysis unit 1 as a raw material. After dry distillation and pyrolysis, oil gas b is produced. In the cooling unit 2, the oil gas b is cooled to obtain slag-containing coal tar c and cooled oil gas d. In the washing unit 3, the slag-containing coal tar c is diluted with detergent e to obtain the slag-containing coal tar f after dilution. In the centrifuge unit 4, the diluted slag-containing coal tar f is centrifuged to obtain oil residue g and deslagging coal tar h containing detergent. In the vacuum flash unit 5, deslagging coal tar h containing detergent is subjected to vacuum flashing to obtain deslagging and deslagging coal tar i and light component j. The deslagging and de-agent coal tar i is sent to the delayed coking unit 6 . After delayed coking, naphtha k and top cycle oil are obtained. At least one of naphtha k and top cycle oil l is ret...

Embodiment 1

[0099] according to figure 1 , carry out embodiment 1. Pulverized coal is used as raw material. The particle size characteristics of pulverized coal are shown in Table 1 below.

[0100] Table 1: Characteristics of particle size distribution of pulverized coal

[0101] Particle size, mm

less than 0.2

0.2-3

3-6

6-13

greater than 13

Mass percentage, %

7.91

27.56

9.69

29.80

25.04

[0102] The pulverized coal a enters the pyrolysis unit 1. In the rotary carbonization reactor, the pulverized coal a is subjected to carbonization and pyrolysis. After dry distillation and pyrolysis, oil gas b is produced. In the cooling unit 2, the oil gas b is cooled to obtain slag-containing coal tar c and cooled oil gas d. The slag-containing coal tar c was analyzed. The mechanical impurity content was 8.06% by weight. The particle size distribution is shown in Table 2 below.

[0103] Table 2: Particle size distribution characteristics of...

Embodiment 2

[0112] In a similar manner to Example 1, Example 2 was carried out, except: the top cycle oil 1 obtained in the retort pyrolysis was also returned to the detergent e.

[0113] The impurity content analysis was carried out on the deslagging and de-agent coal tar i.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com