Envelope microbe modified particle urea and production method and application thereof

A technology of microbial modification and granular urea, which is applied in the fields of application, urea compound fertilizer, and grain cultivation. It can solve the problems of difficult production process, crop defertilization, and easy water absorption, so as to prevent the occurrence of soil-borne diseases and reduce nitrogen elements. The loss of the soil and the effect of activating soil nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

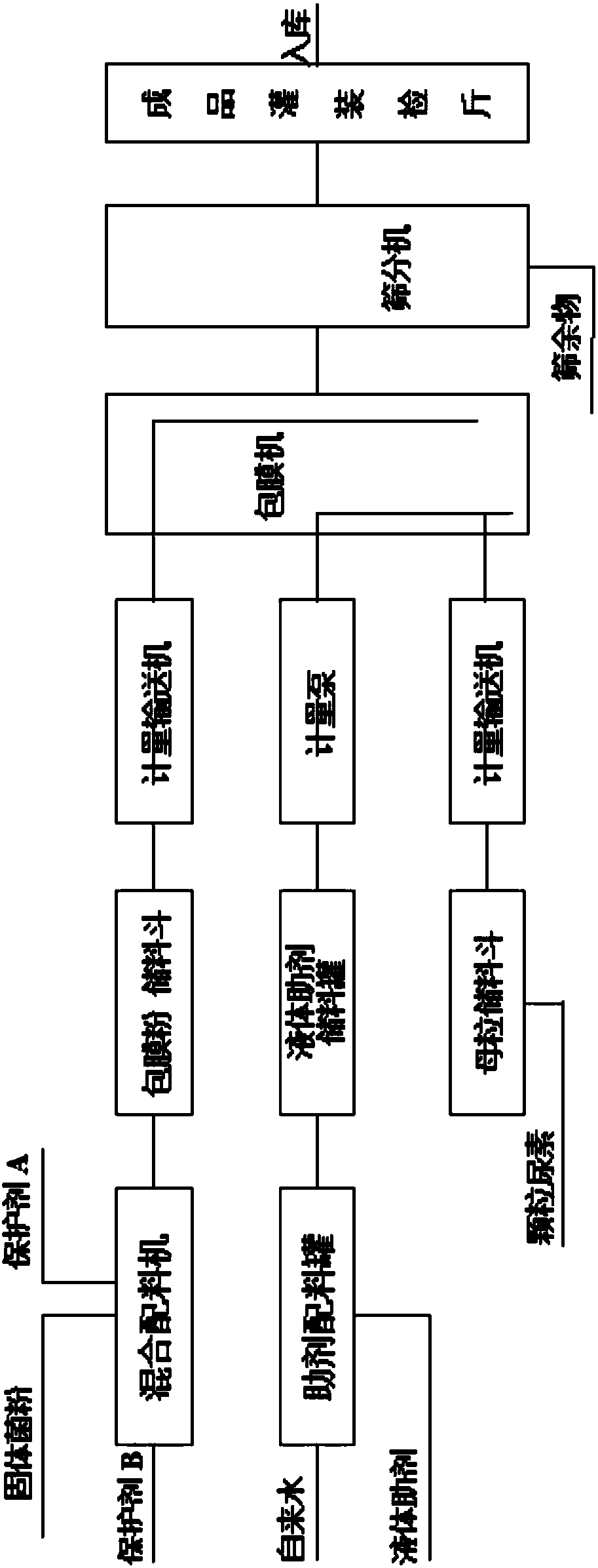

Method used

Image

Examples

Embodiment 1

[0048] A kind of coated microorganism modified granular urea, its preparation method is as follows:

[0049] 1. Weigh 300 kg of granular urea (accounting for 87.2% of the total weight), and put it in the urea storage hopper for use.

[0050] 2. Weigh 6 kg of threonine solution (accounting for 1.75% of the total weight), and put it in a liquid storage tank for use. (Note: The threonine solution is made from 2 kg of threonine and 4 kg of water.)

[0051] 3. Take by weighing 15 kilograms (accounting for 4.36% of total weight) of the solid amylolytic bacteria powder that fineness is greater than 325 orders 100 billion / g, put into the mixer and stand by.

[0052] 4. Weigh 6 kilograms (accounting for 1.75% of total weight) of glucose with a fineness greater than 100 mesh and put it into a mixer for use.

[0053] 5. Weigh 17 kilograms of fineness greater than 325 order light calcium carbonate (accounting for 4.94% of total weight) and put it into the mixer for use.

[0054] 6. Tur...

Embodiment 2

[0057] A kind of coated microorganism modified granular urea, its preparation method is as follows:

[0058] 1. Weigh 380 kg of granular urea (90.05% of the total weight) and put it in the urea storage hopper for use.

[0059] 2. Weigh 4 kg of lysine solution (accounting for 0.95% of the total weight), and put it in the liquid storage tank for use; (note: the lysine solution is made of 1.32 kg of lysine and 2.68 kg of water.)

[0060] 3. Weigh 1 kilogram (accounting for 0.24% of the total weight) of solid amylolytic bacteria powder with a fineness greater than 325 mesh 100 billion / g, and put it into a mixer for use;

[0061] 4. Weigh 2 kilograms of glucose (accounting for 0.47% of the total weight) with a fineness greater than 100 mesh, and put it into a mixer for use.

[0062] 5. Weigh 35 kilograms of calcium carbonate powder (accounting for 8.29% of total weight) with a fineness greater than 325 objects and put it into a mixer for use.

[0063] 6. Turn on the mixer and mix...

experiment example 1

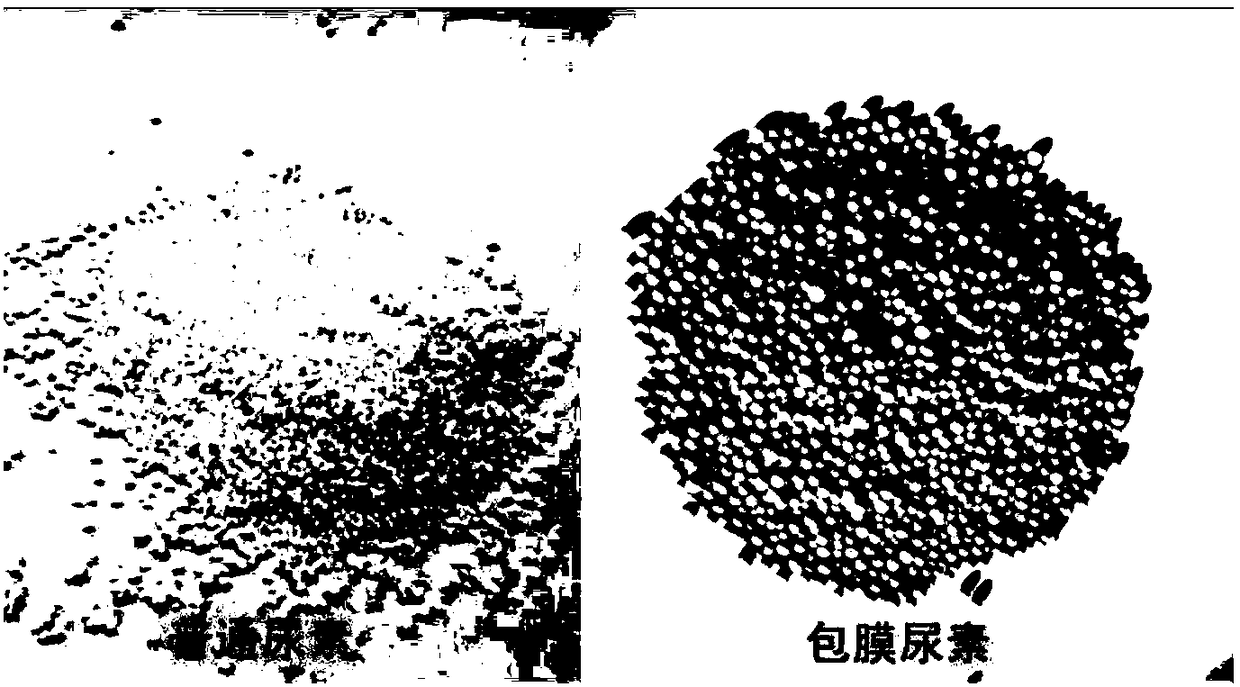

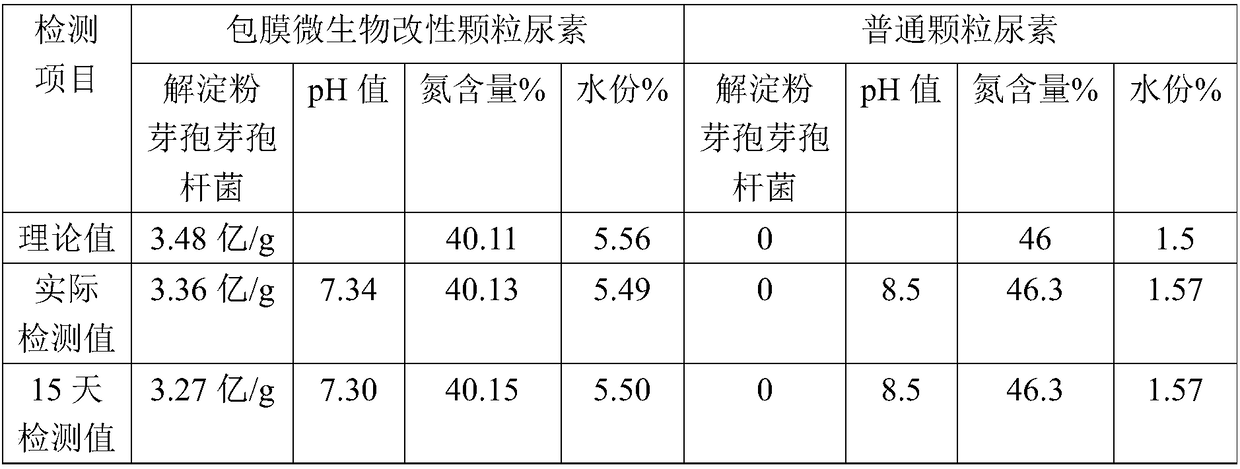

[0065] Experimental Example 1 Coated Microorganism Modified Granular Urea

[0066] Overview: Urea is a simple chemical fertilizer with a nitrogen content of 46%. Nitrogen exists in the form of amide nitrogen. Its chemical properties are alkaline and its pH value is between. It has some physical and chemical properties of alkaline inorganic salts and organic salts. The fertilizer effect is single, the dissolution rate is fast when applied, the loss is large, and the utilization rate is low. According to these properties, several raw materials such as threonine, lysine, acetic acid, etc. are selected for physical and chemical reactions with urea, and urea threonine salt, urea lyonate or urea with strong adsorption is generated on the surface of urea Acetate changes the structure and form of amido nitrogen to adhere to and protect various functional bacteria from being killed by amido nitrogen, and protect the long-term survival of beneficial bacteria. The corresponding protecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com