Chemically amplified photoresist

A photoresist and chemical technology, applied in the field of photoacid generators, can solve the problems such as the destruction of the rectangular shape of the photoresist pattern and the reduction of the resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preferred embodiments of the present invention are described below.

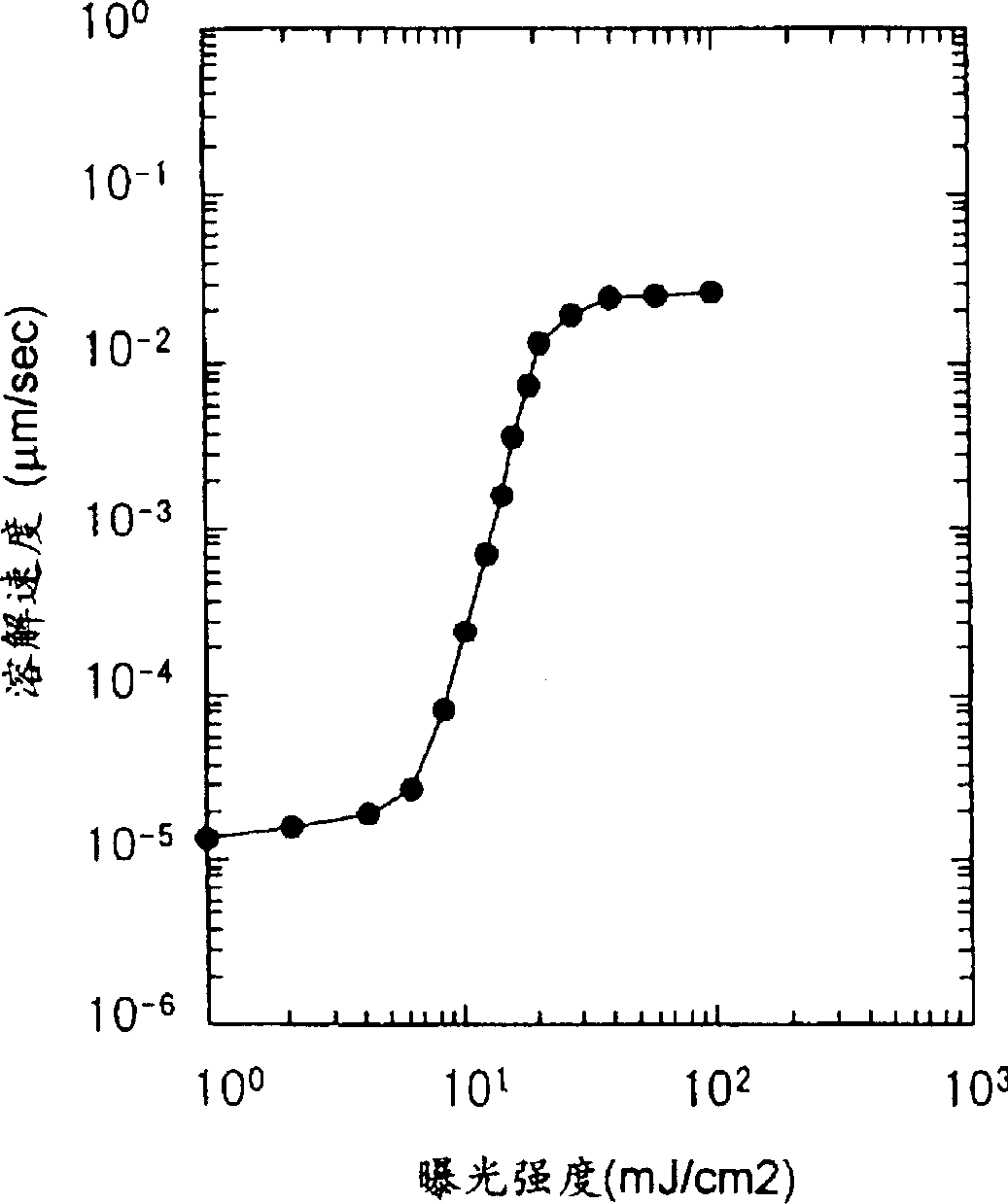

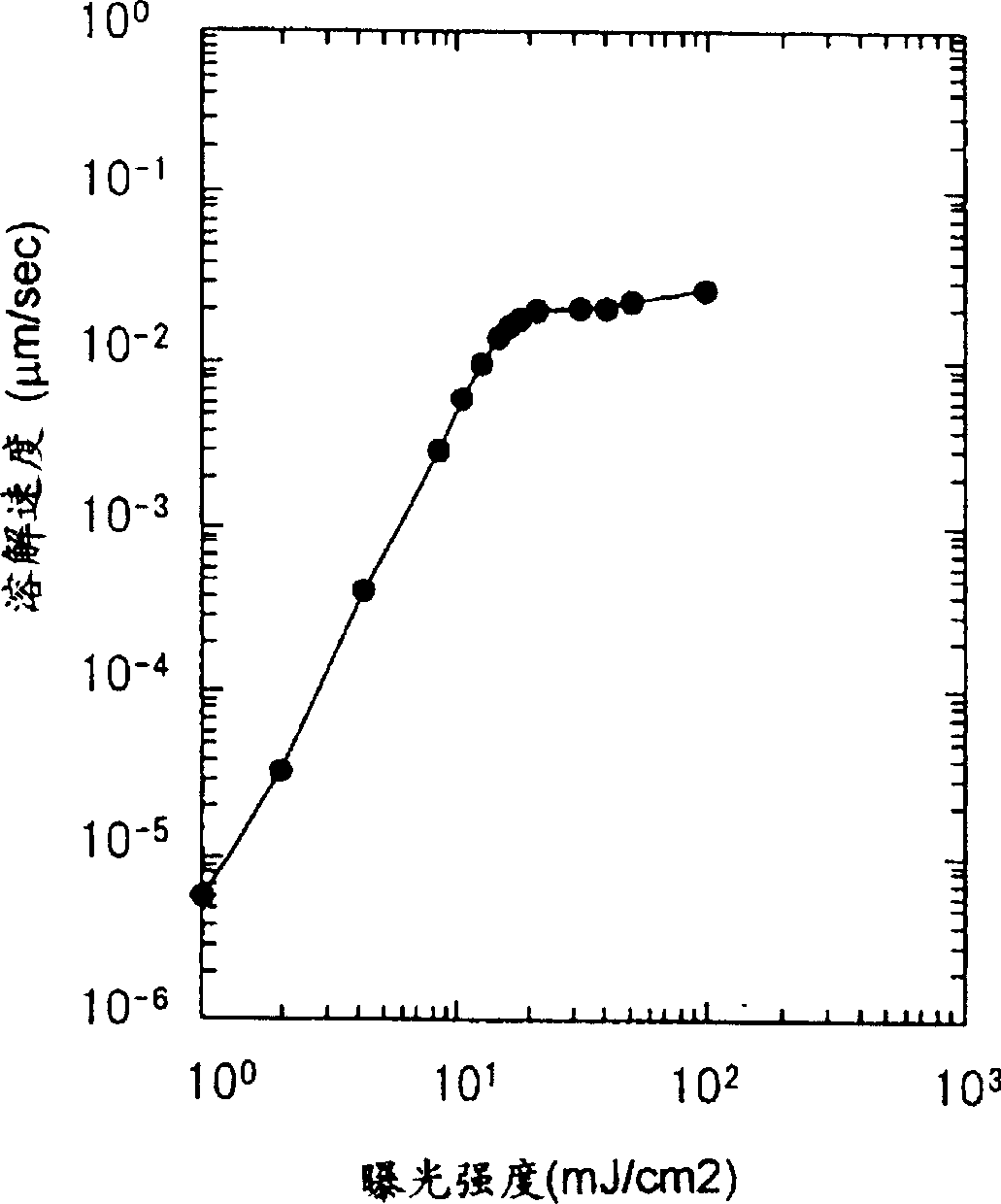

[0021] In the chemically amplified photoresist of the present invention, a polyhydroxystyrene polymer is used as the matrix polymer, and the polyhydroxystyrene polymer has a protecting group whose polarity is converted by an acid catalyst, for the For the protected polyhydroxystyrene polymers, mixtures of polymers of different average molecular weights were used. That is, a mixture of a protected polyhydroxystyrene polymer having a relatively high average molecular weight (hereinafter referred to as a high molecular weight polymer) and a polymer having a relatively low molecular weight (referred to as a low molecular weight polymer) is used as the present invention. Invented matrix polymer. There is no limit to the number of species of protected polyhydroxystyrene polymers constituting the matrix mixture. However, in the following description it is represented by a high molecular weight polymer and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com