Preparation method for stainless steel and carbon steel composite tube liable to weld and coat edges

A stainless steel, easy-to-weld technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0006] The present invention is achieved like this, it is characterized in that implementation method is as follows:

[0007] (1) The stainless steel and carbon steel clad plate manufactured with the application number 201610078667.2 and the title of the invention "A method for manufacturing an easy-to-weld cladding stainless steel clad plate" is used as the blank;

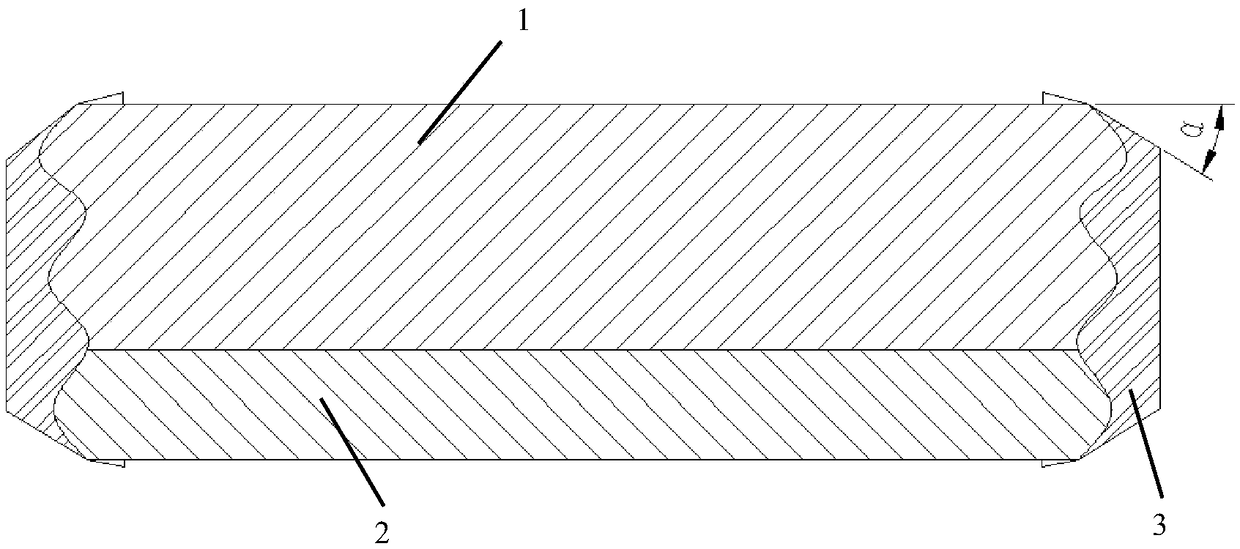

[0008] (2) Mill out the welding groove with an included angle α of 45°-60° around the cladding of the above stainless steel and carbon steel composite plate, and use a grinding wheel to remove impurities such as iron oxide scale to make the surface smooth, such as figure 1 shown;

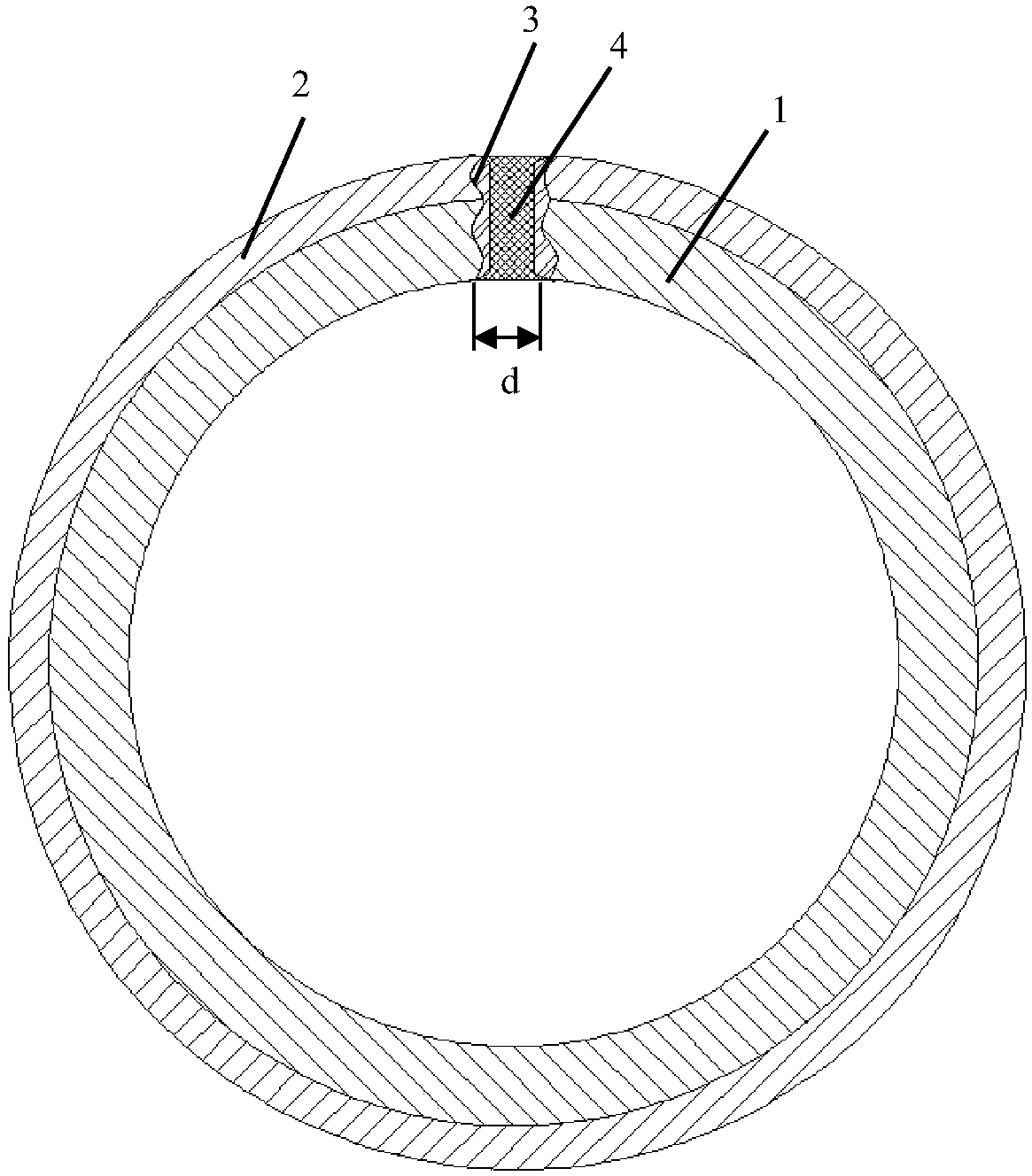

[0009] (3) Use ultrasonic waves to detect flaws on the above-mentioned stainless steel and carbon steel composite plates, and use the JCO forming method on the bending machine to bend the stainless steel composite plates into an open tubular shape. The mouth opening distance d is 10-15mm, such as figure 2 shown;

[0010] (4) Use wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com