Hot cathode-based gas discharge electron source

A gas discharge and electron source technology, which is applied in the thermionic cathode, electron emission electrode/cathode, traveling wave tube, etc., can solve the problem that the hot cathode of the space traveling wave tube cannot achieve fast startup, and the gas discharge hollow cathode has high working power and cannot be used. To meet the needs of small satellite systems and other issues, to achieve the effect of providing work efficiency, increasing cathode emission current, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

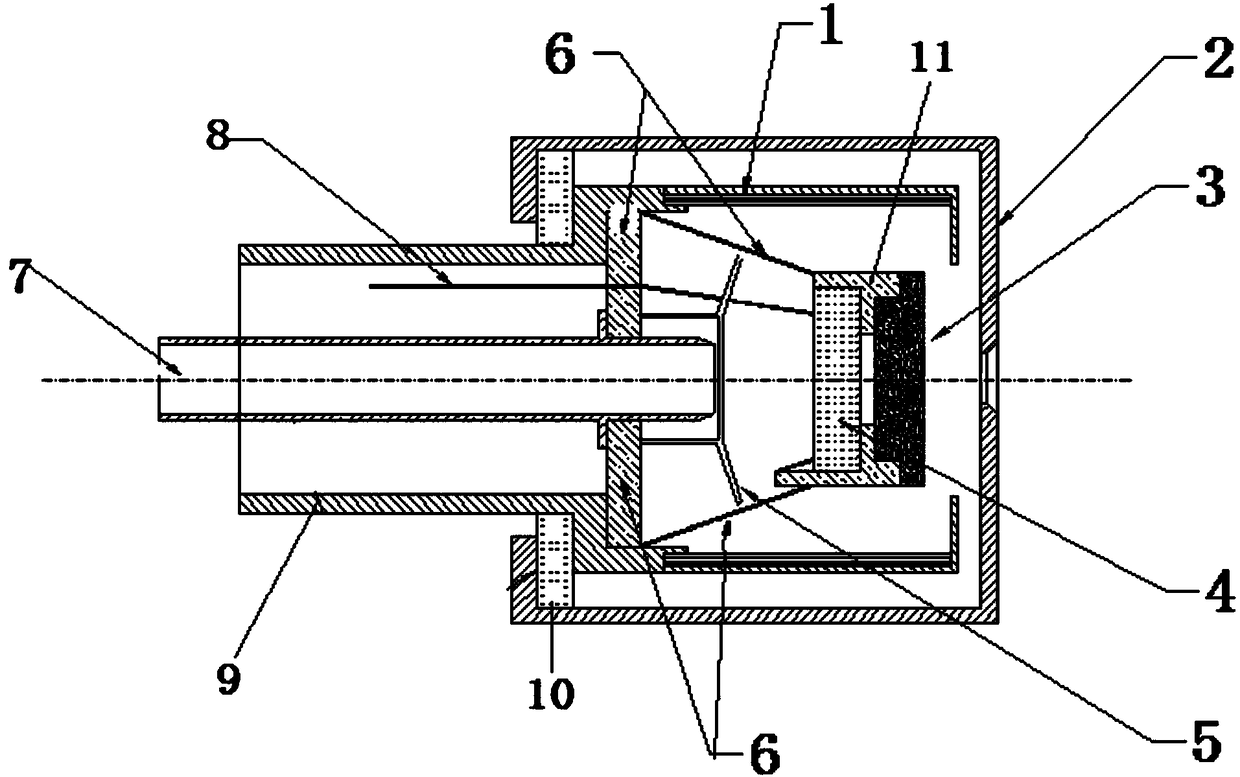

[0025] Such as figure 1 As shown, a gas discharge electron source based on a hot cathode provided in this embodiment includes: a heat shield part 1, an anode cover 2, an emitter 3, a hot wire part, a gas distribution baffle 5, a cathode support part 6, and a gas supply pipe Road 7, power supply positive input terminal 8 and heat shield support part 9;

[0026] Wherein, the heating wire component includes a heating wire 4 and a heating wire insulating ceramic 11, one end of the heating wire is connected to the positive input terminal 8 of the power supply, and the other end is connected to the cathode support member 6, and the cathode support member 6 is connected to the power supply ground. The heating wire is matched with the emitter 3 through the heating wire insulating ceramic 11, so that the heating wire 4 is opposite to the emitter 3 but not in conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com