Technology parameter optimization method of bar rolling of three-roll planetary mill

A technology of process parameter optimization and planetary rolling mill, applied in the direction of neural learning method, design optimization/simulation, electrical digital data processing, etc., can solve the problem of determining, staying, and unsatisfied technical parameters of rolling bar with three-roll planetary rolling mill The needs of processing technology research and other issues, to achieve the effect of less possibility of core cracking, full play of production potential, and avoidance of production potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for optimizing process parameters of bar rolling in a three-high planetary rolling mill. The rod described in this embodiment is a bismuth-containing stainless steel rod with a diameter of 32.5mm, and the specific steps of the process parameter optimization method are:

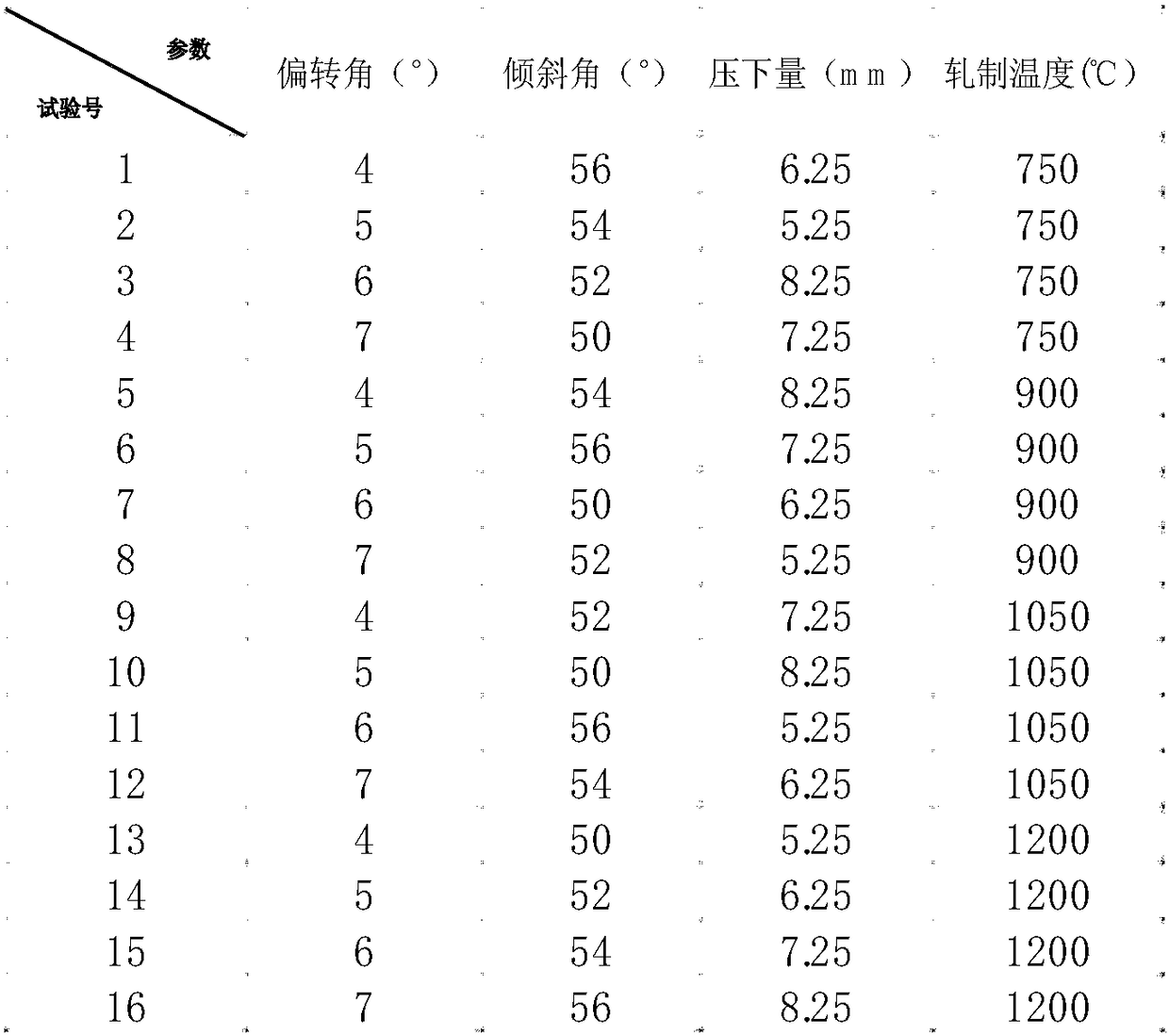

[0026] The first step, the determination of the orthogonal test plan for finite element simulation

[0027] Determine the ranges corresponding to the deflection angle interval, inclination angle interval, reduction amount interval and rolling temperature interval of the rolled bar of the three-roll planetary rolling mill as 4~7°, 50~56°, 5.25~8.25mm and 750~1200°C . In the deflection angle interval, the preselected 4 deflection angle horizontal values are 4°, 5°, 6° and 7° respectively, and in the inclination angle interval, the preselected 4 inclination angle horizontal values are respectively 50°, 52°, 54° and 56°, pre-select 4 reduction levels in the reduction range, respectively 5.25m...

Embodiment 2

[0040] A method for optimizing process parameters of bar rolling in a three-high planetary rolling mill. The rod described in this embodiment is a titanium rod with a diameter of 32mm, and the specific steps of the process parameter optimization method are:

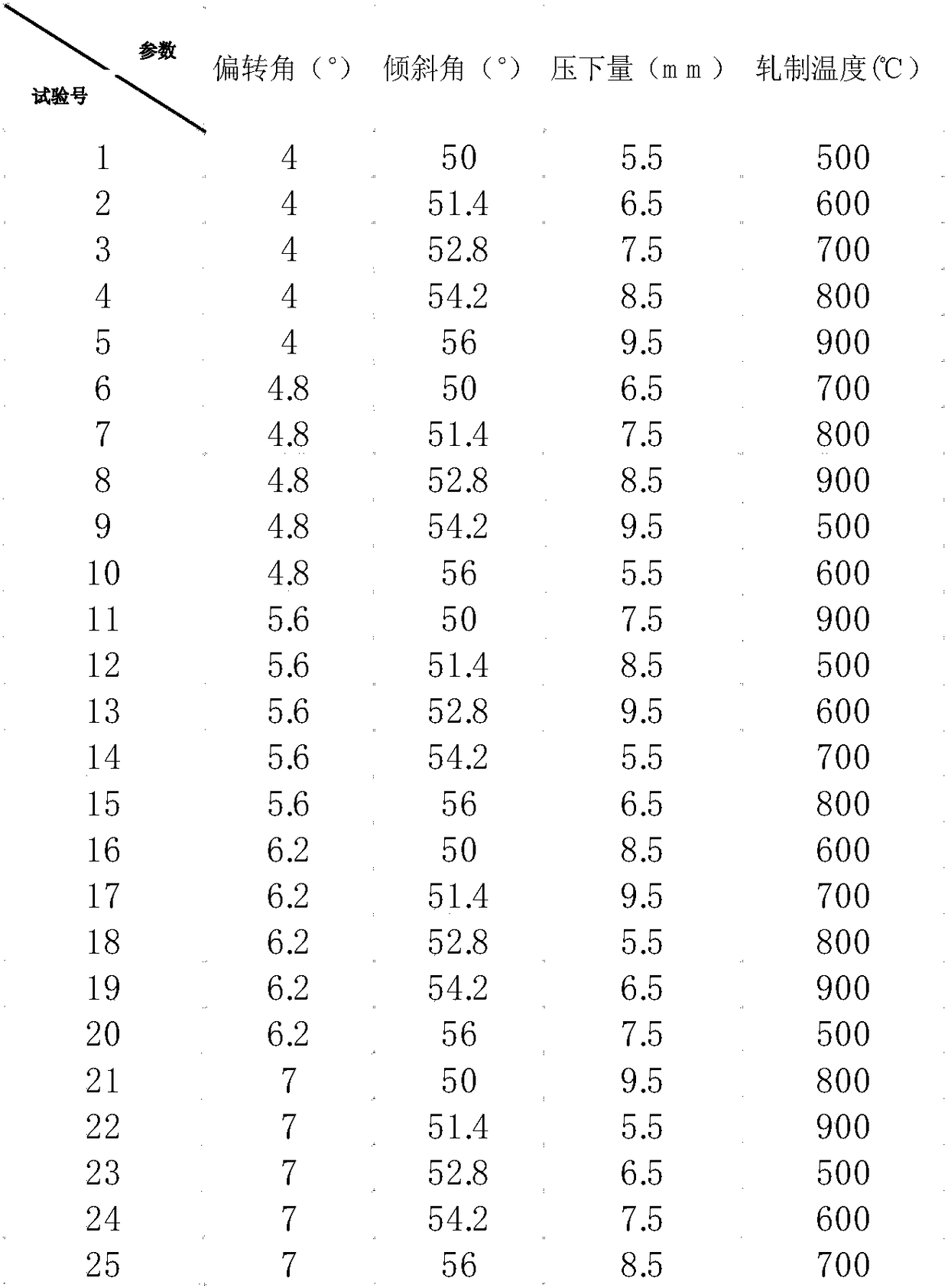

[0041] The first step, the determination of the orthogonal test plan for finite element simulation

[0042] Determine the ranges corresponding to the deflection angle interval, inclination angle interval, reduction amount interval and rolling temperature interval of the rolled bar of the three-roll planetary rolling mill as 4-7°, 50-56°, 5.5-9.5mm and 500-900°C . In the deflection angle interval, five preselected deflection angle horizontal values are 4°, 4.8°, 5.6°, 6.2° and 7° respectively, and five inclination angle horizontal values are respectively 50°, 50°, 51.4°, 52.8°, 54.2° and 56°, pre-selected 5 reduction levels in the range of the reduction are 5.5mm, 6.5mm, 7.5mm, 8.5mm, 9.5mm, in the rolling The five ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com