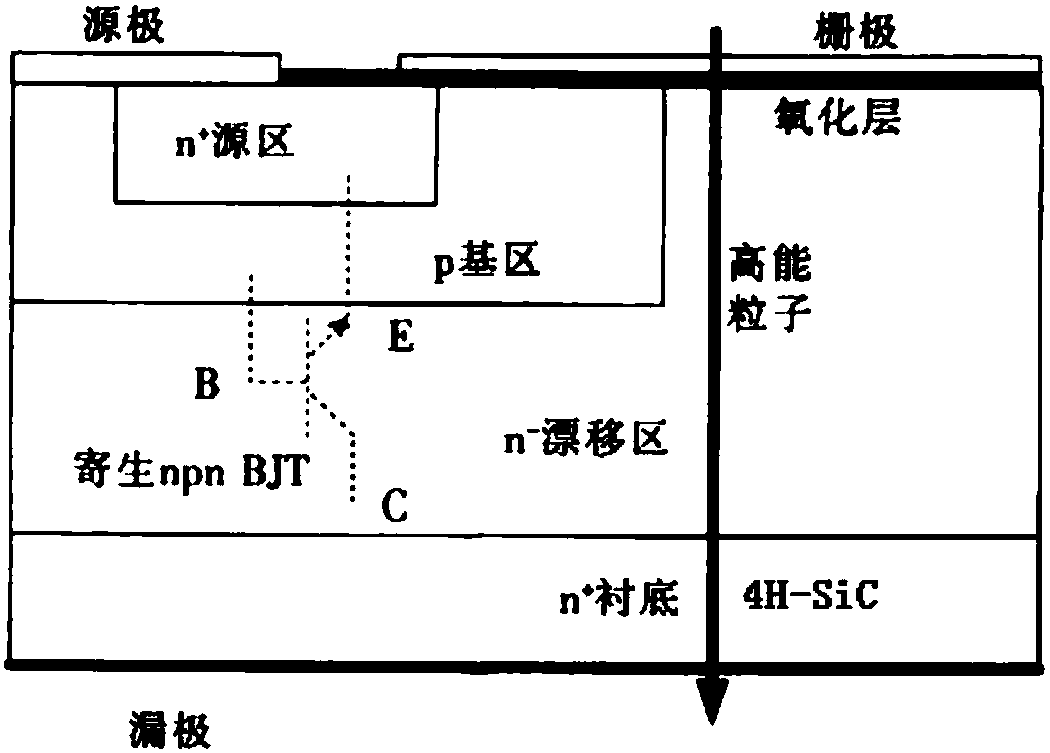

Analytical method for safety boundary performance degradation of single-particle irradiated silicon carbide power MOSFETs

A technology of irradiating silicon carbide and safety margins, which is applied in the electronic field, can solve problems such as the inability to design MOSFETs devices and the inability to accurately obtain the safety margins of SiC power MOSFETs devices, and achieve the effect of increasing utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0038] Such as figure 2 As shown, an analysis method for the performance degradation of the safety boundary of SiC power MOSFETs irradiated by single events includes the following steps:

[0039] Step 1. Use heavy ions or protons to irradiate silicon carbide SiC power MOSFETs devices with single particles to obtain test data of single particle burnout or gate breakdown. The specific process is as follows:

[0040] (1) Experimental design scheme for single-particle irradiation silicon carbide SiC power MOSFETs devices, preparation of samples and single-particle detection system;

[0041] (2) Install the sample to be tested;

[0042] (3) Apply a reverse bias voltage to the sample: drain-source reverse bias voltage V DSi , Gate-source reverse bias voltage V GSi ;

[0043] (4) Set the upper limit of the SiC power device current (subject to the electrical characteristic specification of the specific product), connect a high-precision multimeter in series with the drain-source ...

specific Embodiment approach 2

[0056] An analysis method for performance degradation of silicon carbide power MOSFETs safety boundary by single-event irradiation, comprising the following steps:

[0057] Step 1. Use heavy ions or protons to irradiate silicon carbide SiC power MOSFETs devices with single particles to obtain test data of single particle burnout or gate breakdown. The specific process is as follows:

[0058] (1) Experimental design scheme for single-particle irradiation silicon carbide SiC power MOSFETs devices, preparation of samples and single-particle detection system;

[0059] (2) Install the sample to be tested;

[0060] (3) Apply a reverse bias voltage to the sample: drain-source reverse bias voltage V DSi , Gate-source reverse bias voltage V GSi ;

[0061] (4) Set the upper limit of the SiC power device current (subject to the electrical characteristic specification of the specific product), connect a high-precision multimeter in series with the drain-source circuit of the device und...

specific Embodiment approach 3

[0073] An analysis method for performance degradation of silicon carbide power MOSFETs safety boundary by single-event irradiation, comprising the following steps:

[0074] Step 1. Use heavy ions or protons to irradiate silicon carbide SiC power MOSFETs devices with single particles to obtain test data of single particle burnout or gate breakdown. The specific process is as follows:

[0075] (1) Experimental design scheme for single-particle irradiation silicon carbide SiC power MOSFETs devices, preparation of samples and single-particle detection system;

[0076] (2) Install the sample to be tested;

[0077] (3) Apply a reverse bias voltage to the sample: drain-source reverse bias voltage V DSi , Gate-source reverse bias voltage V GSi ;

[0078] (4) Set the upper limit of the SiC power device current (subject to the electrical characteristic specification of the specific product), and connect it in series with the drain-source circuit of the device under test through a high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com