Ultrafine high-purity AlON powder and preparation method thereof

A powder, high-fine technology, applied in the field of ultra-fine high-purity AlON powder and its preparation, can solve the problems of high temperature of AlON powder, large powder particle size, unfavorable pore exclusion, etc., to achieve a simple and controllable preparation process, Actionable, small-grained effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

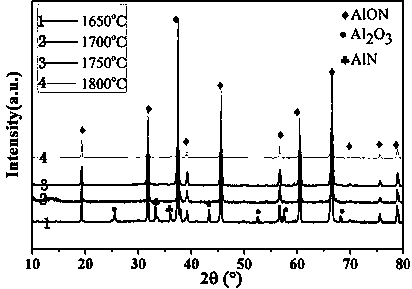

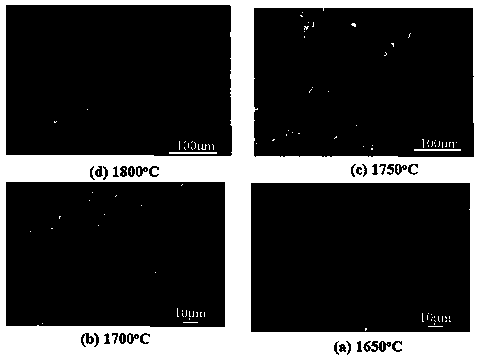

Embodiment 1

[0024] Mix alumina powder, carbon powder and absolute ethanol according to a certain mass ratio, wherein the content of carbon powder in the mixed slurry is controlled at 5.4wt%, Al 2 o 3 The mass ratio of powder to absolute ethanol is 1:20, magnetic stirring and ultrasonic dispersion are carried out at room temperature for 20 minutes to obtain a mixed slurry; then the mixed slurry is put into a polytetrafluoroethylene tank for planetary ball milling for 12 hours, and the ball milling medium Alumina balls; put the ball-milled slurry into a vacuum drying oven and dry at 80°C for 2 hours to obtain a mixed powder; then pass through a 200-mesh sieve after grinding for later use; weigh a certain amount of mixed powder, and put it in a flowing nitrogen atmosphere high temperature treatment. The sintering process is atmosphere pressure sintering: it is completed in two steps. First, the obtained mixed powder was heated up to 1450°C at 10°C / min and kept for 2 hours under the protect...

Embodiment 2

[0026] Mix alumina powder, carbon powder and absolute ethanol according to a certain mass ratio, wherein the content of carbon powder in the mixed slurry is controlled at 6wt%, Al 2 o 3 The mass ratio of powder to absolute ethanol is 1:20, magnetic stirring and ultrasonic dispersion are carried out at room temperature for 20 minutes to obtain a mixed slurry; then the mixed slurry is put into a polytetrafluoroethylene tank for planetary ball milling for 12 hours, and the ball milling medium Alumina balls; put the ball-milled slurry into a vacuum drying oven and dry at 80°C for 2 hours to obtain a mixed powder; then pass through a 200-mesh sieve after grinding for later use; weigh a certain amount of mixed powder, and put it in a flowing nitrogen atmosphere high temperature treatment. The sintering process is atmosphere pressure sintering: it is completed in two steps. First, the obtained mixed powder is heated up to 1450°C at 10°C / min under the protection of flowing high-puri...

Embodiment 3

[0028] Mix alumina powder, carbon powder and absolute ethanol according to a certain mass ratio, wherein the content of carbon powder in the mixed slurry is controlled at 6.5wt%, Al 2 o 3 The mass ratio of powder to absolute ethanol is 1:20, magnetic stirring and ultrasonic dispersion are carried out at room temperature for 20 minutes to obtain a mixed slurry; then the mixed slurry is put into a polytetrafluoroethylene tank for planetary ball milling for 12 hours, and the ball milling medium Alumina balls; put the ball-milled slurry into a vacuum drying oven and dry at 80°C for 2 hours to obtain a mixed powder; then pass through a 200-mesh sieve after grinding for later use; weigh a certain amount of mixed powder, and put it in a flowing nitrogen atmosphere high temperature treatment. The sintering process is atmosphere pressure sintering: it is completed in two steps. Firstly, the obtained mixed powder was heated up to 1550°C at 10°C / min under the protective condition of fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com