A kind of doping modified nickel oxide base NTC thermistor material and preparation method thereof

A thermistor and raw material technology, applied in the field of NTC thermistor materials, can solve the problems of material aging, affecting material performance and service life, unstable electrical performance, etc., and achieve low sintering temperature, high flexibility and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment according to the molecular formula Ni 1-x Al x o 1-y f y Dosing was performed where x=0, y=0.04. The initial raw material is selected from basic nickel carbonate NiCO 3 2Ni(OH) 2 4H 2 O, ammonium fluoride NH 4 F. Materials were prepared according to the following experimental process steps:

[0022] (1) The initial raw material is NiO 0.96 f 0.04 Ingredients, weigh NiCO 3 2Ni(OH) 2 4H 2 O 62.7050g, NH 4 F0.7408g;

[0023](2) Dissolve the raw materials weighed in the previous step: NiCO 3 2Ni(OH) 2 4H 2 O was dissolved in dilute nitric acid, and then ammonia water was added dropwise to adjust the pH value to about 8; NH 4 F is dissolved in distilled water;

[0024] (3) Mix the two solutions prepared in the previous step together, and use a magnetic stirring heater to stir and mix evenly, heat and dry;

[0025] (4) Calcining the powder obtained in the previous step at a temperature of 850° C. and keeping it warm for 5 hours;

[0026] (...

Embodiment 2

[0032] This embodiment according to the molecular formula Ni 1-x al x o 1-y f y Dosing was performed where x = 0.003, y = 0.04. The initial raw material is selected from basic nickel carbonate NiCO 3 2Ni(OH) 2 4H 2 O, ammonium fluoride NH 4 F, aluminum isopropoxide C 9 h 21 AlO 3 . Materials were prepared according to the following experimental process steps:

[0033] (1) The initial raw material is Ni 0.997 al 0.003 o 0.96 f 0.04 Formulation ingredients, weigh NiCO 3 2Ni(OH) 2 4H 2 O62.5169g, NH 4 F 0.7408g, C 9 h 21 AlO 3 0.3064g;

[0034] (2) Dissolve the raw materials weighed in the previous step, wherein NiCO 3 2Ni(OH) 2 4H 2 After O is dissolved in dilute nitric acid, ammonia water is added to adjust the pH value to about 8. NH 4 F dissolved in distilled water, C 9 h 21 AlO 3 Soluble in ethanol;

[0035] (3) The preparation process is the same as steps (3) to (8) in Example 1

[0036] The properties of the prepared materials are shown in T...

Embodiment 3

[0038] This example according to molecular formula Ni 1-x al x o 1-y f y Dosing was performed where x = 0.005, y = 0.04. The initial raw material is selected from basic nickel carbonate NiCO 3 2Ni(OH) 2 4H 2 O, ammonium fluoride NH 4 F, aluminum isopropoxide C 9 h 21 AlO 3 . . Materials were prepared according to the following experimental process steps:

[0039] (1) The initial raw material is Ni 0.995 al 0.005 o 0.96 f 0.04 Formulation ingredients, weigh NiCO 3 2Ni(OH) 2 4H 2 O62.3915g, NH 4 F 0.7408g, C 9 h 21 AlO 3 0.5106g;

[0040] (2) The preparation process is the same as steps (2)-(3) in Example 2.

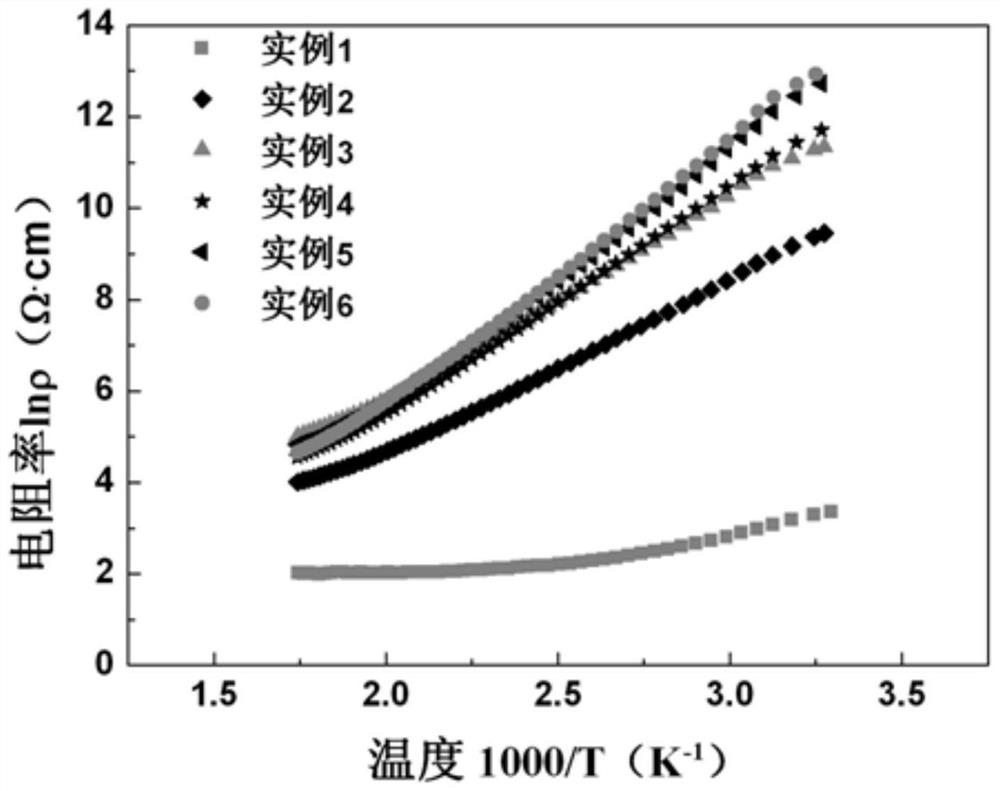

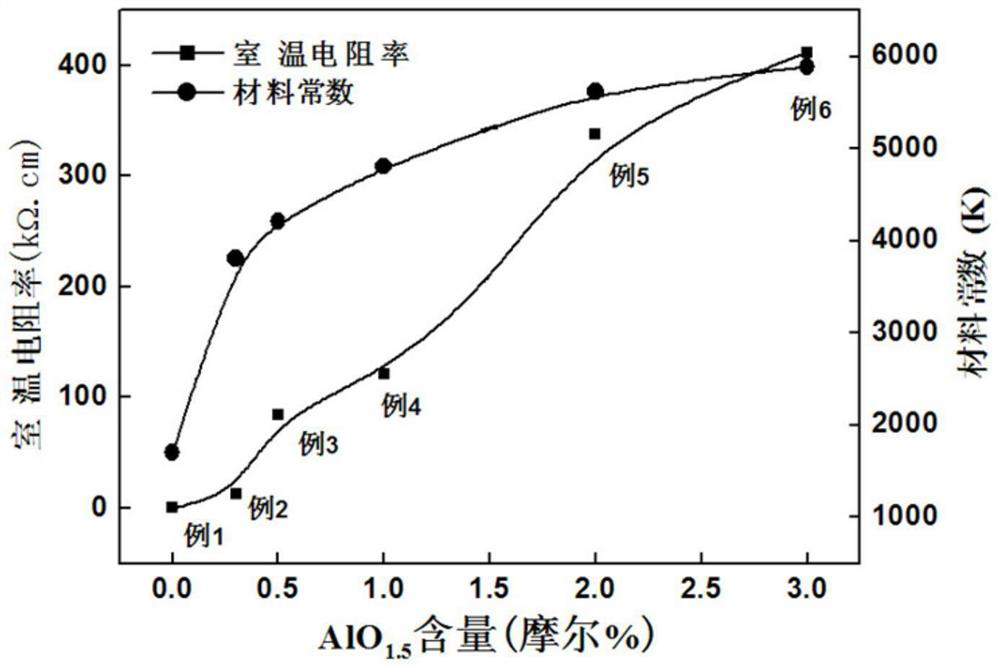

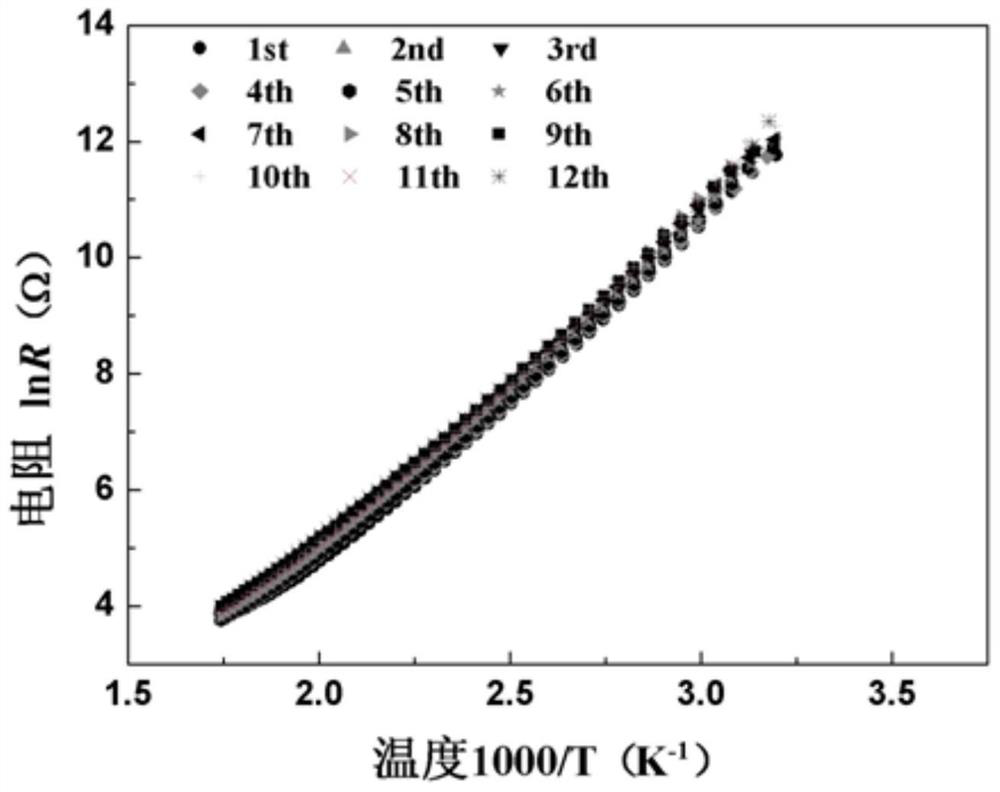

[0041] The properties of the prepared materials are shown in Table 1. figure 1 and figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com