Carbon/fish-sourced collagen membrane composite material and preparation method of same

A composite material and collagen film technology, which is applied in the field of carbon/fish source collagen film composite materials and its preparation, can solve problems such as inability to fully utilize, cytotoxicity, and loss of the inherent shape of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

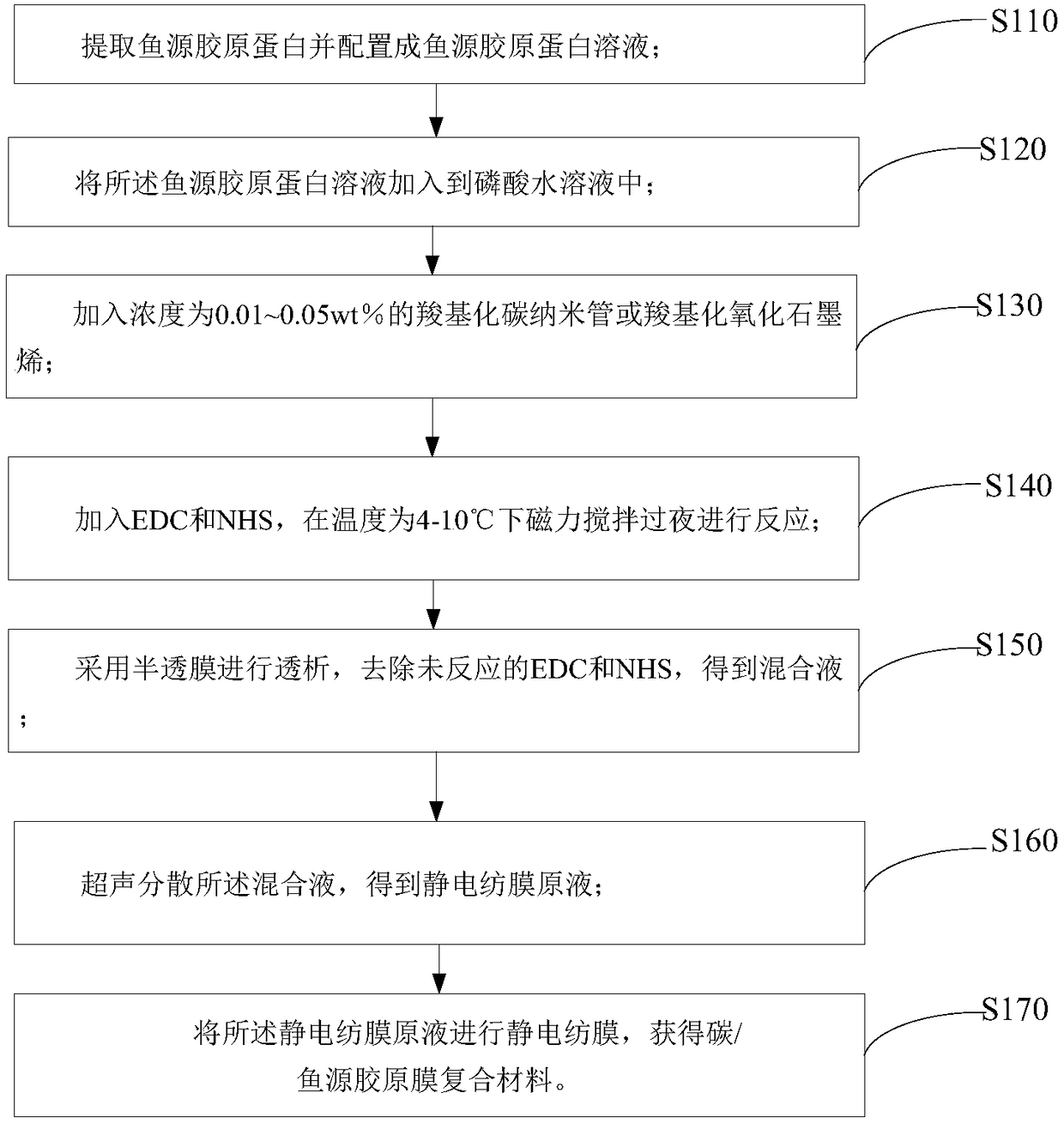

[0032] see figure 1 , the preparation method of the carbon / fish source collagen membrane composite material preparation method of one embodiment, comprises the following steps:

[0033] S110, extracting fish-derived collagen and configuring it into a fish-derived collagen solution.

[0034] In one embodiment, the solvent of the fish-derived collagen solution is acetic acid, the concentration of the fish-derived collagen solution is 1-4 mg / mL, and the volume of the fish-derived collagen solution is 10-40 ml.

[0035] In one embodiment, the fish-derived collagen is extracted from tilapia or cod skin.

[0036] In one embodiment, the preparation method of extracting fish-derived collagen is:

[0037] The tilapia skin is defatted by using 10%-15% n-butanol by volume percentage for 24h-48h to obtain the defatted fish skin. In one embodiment, the mass volume ratio w / v of tilapia fish skin and n-butanol is 1:20~1:40; the mass volume ratio w / v of defatted fish skin and NaOH aqueous ...

Embodiment 1

[0061] Take 15g of tilapia fish skin and degrease it with 10% (v) n-butanol (w / v=1:20) for 24h (replace once every 8h), wash it with distilled water and soak it in an aqueous NaOH solution with a concentration of 0.1mol / L for 24h ( w / v=1:20) to remove non-collagen components (replace every 8 hours), wash with water until neutral. Then add 0.5mol / L acetic acid solution (w / v=1:50) and 1% pepsin (750U, Sigma), extract with magnetic stirring at 4°C for 48h, centrifuge at 10000r / min for 30min, and the supernatant is the enzymatic solubility Collagen. Add NaCl to the supernatant to a final concentration of C(NaCl)=0.9mol / L, centrifuge, collect the precipitate and dissolve it in 0.5mol / L acetic acid solution, and use 0.02mol / L NaCl 2 HPO 4 The solution (pH8.6) was dialyzed for 24 hours, and the precipitate was collected by centrifugation, redissolved in 0.5 mol / L acetic acid solution, dialyzed with 0.1 mol / L acetic acid solution for 1 day, and then dialyzed with distilled water for...

Embodiment 2

[0064] Cod was used to extract collagen, and the preparation of collagen was carried out according to the method of Nagai and Suzuki (2000). Take 100g pollock skin and soak it in NaOH aqueous solution with a concentration of 0.1mol / L for 24h (1:20w / w) to remove non-collagenous components, wash it to neutrality and add acetic acid solution with a concentration of 0.5mol / L (1:20w / w) homogenate, extract with magnetic stirring at 4°C for 2 days, centrifuge at 10,000 r / min for 30 minutes, and the supernatant is acid-soluble collagen. Add NaCl to the supernatant until the final C(NaCl)=0.9mol / L, centrifuge, collect the precipitate and dissolve it in 0.5mol / L acetic acid solution, dialyze with 0.1mol / L acetic acid solution for 1d, then dialyze with distilled water for 2d, freeze Dried pollock skin acid soluble collagen.

[0065] The collagen is prepared into a solution, and 10mL of the fish-derived collagen solution is added to 1g of an acidic aqueous solution whose pH value is adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com