A method for laser synthesis of magnetic graphene-peg-γ-Fe2O3 composites

A magnetic graphene, laser synthesis technology, applied in pharmaceutical formulations, preparations for in vivo experiments, MRI/MRI contrast agents, etc., can solve the problems of complex experimental steps, low yield, cytotoxicity, etc., and achieve simple The effect of the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

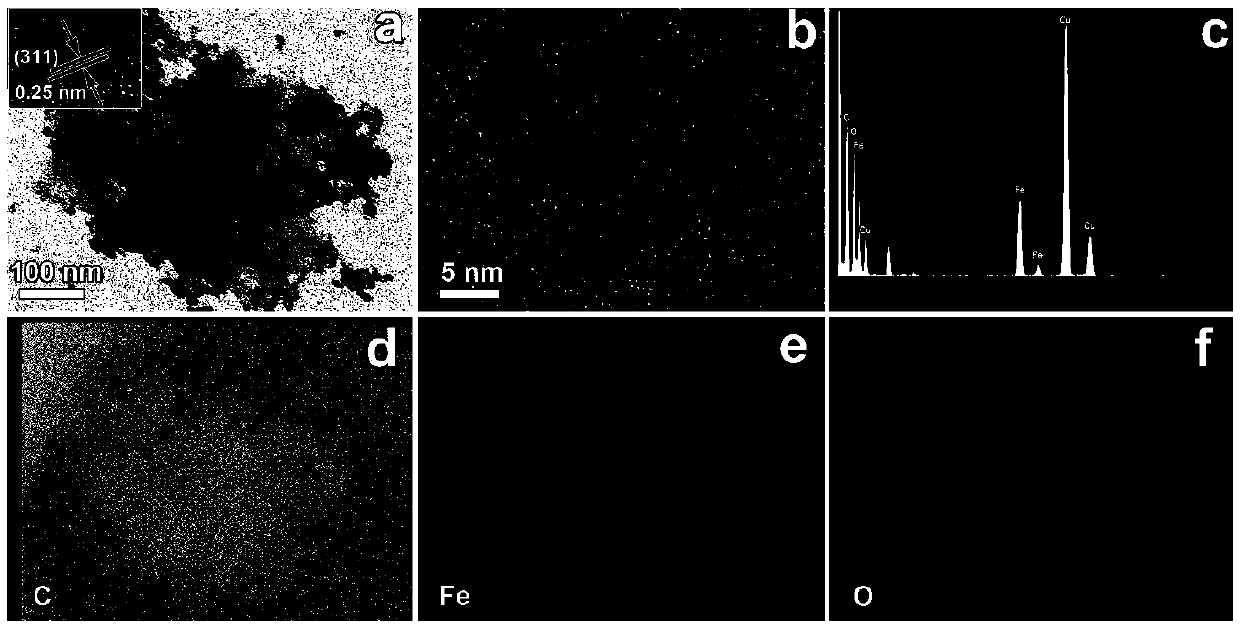

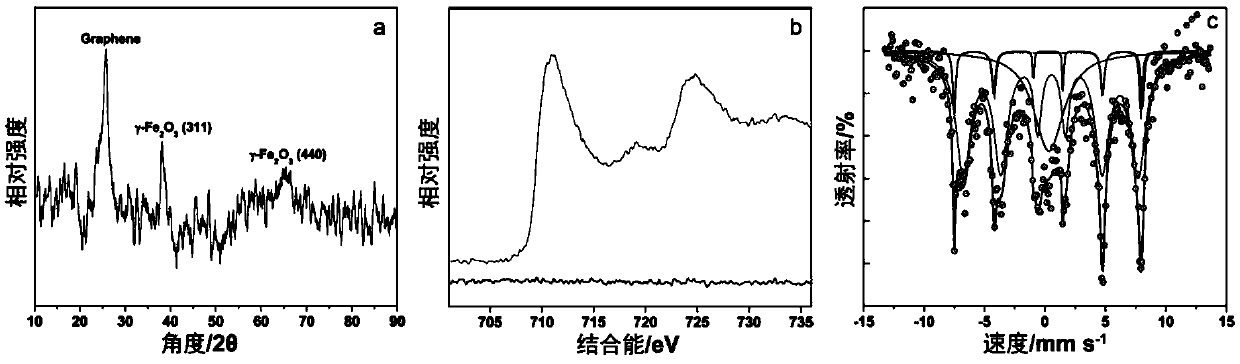

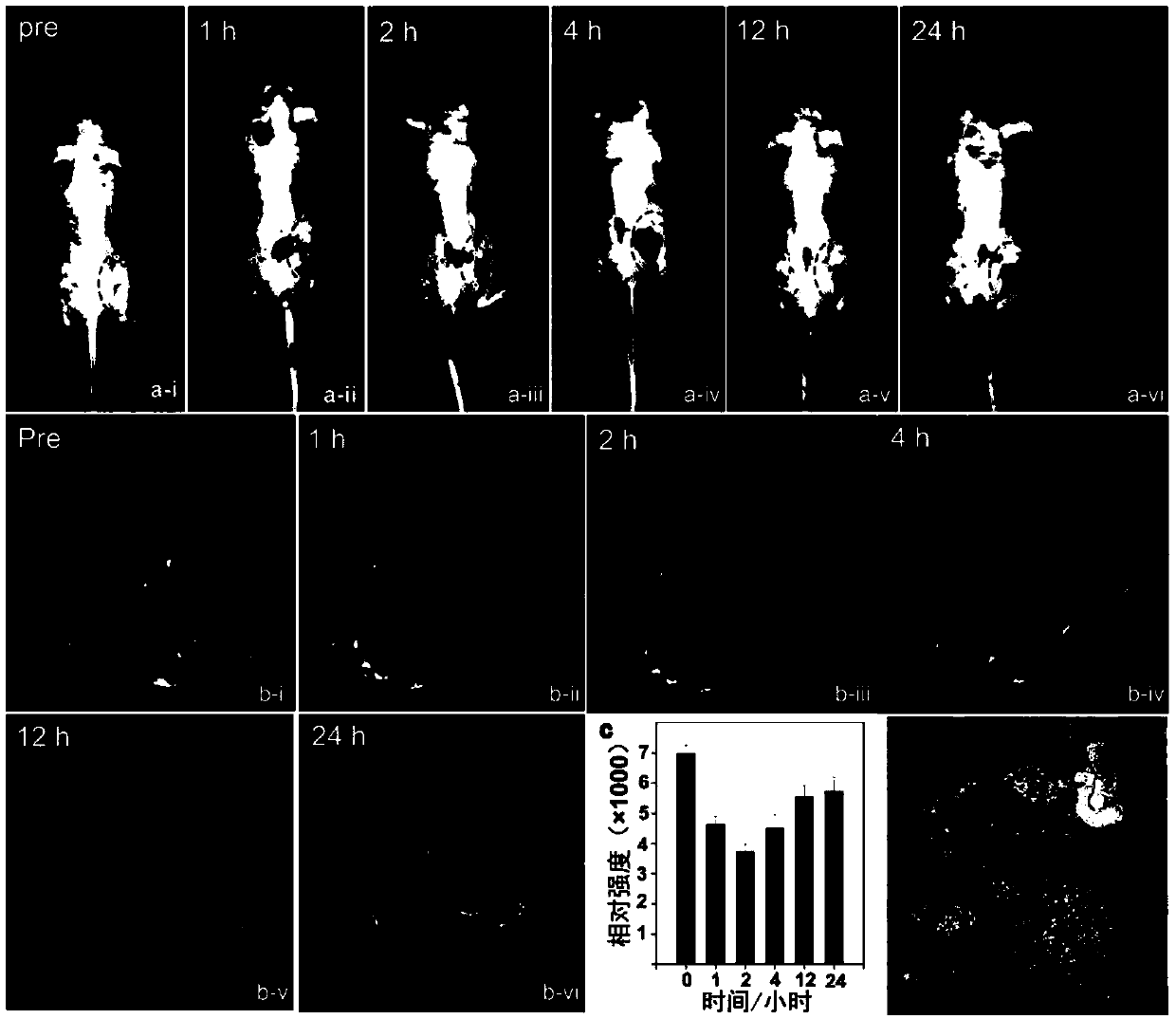

[0019] This embodiment provides a method for synthesizing graphene-PEG-γ-Fe by nanosecond laser ablation in liquid phase 2 o 3 A compound method comprising the steps of:

[0020] (1) Using a block iron target with a purity of 99.9% as a raw material, polish the surface of the target with sandpaper, and ultrasonically clean it with dilute hydrochloric acid to remove its oxide layer; then ultrasonically clean the surface of the iron target twice with deionized water to remove Residual dilute hydrochloric acid, then dry the iron target for use;

[0021] (2) Put the dry iron target in a 50 ml beaker, add 20 ml of graphene-PEG solution with a concentration of 0.2 mg / mL, so that the liquid level above the iron target is 0.5-1.5 cm;

[0022] (3) Start the nanosecond laser, and use focused light with a wavelength of 1064 nanometers to ablate the iron target in step (2), wherein the laser energy, frequency, and action time are 180-250 mJ, 10-15 Hz, 30- 40 minutes; the target is move...

Embodiment 2

[0025] This embodiment provides a method for synthesizing graphene-PEG-γ-Fe by nanosecond laser ablation in liquid phase 2 o 3 A compound method comprising the steps of:

[0026] (1) Using a block iron target with a purity of 99.9% as a raw material, polish the surface of the target with sandpaper, and ultrasonically clean it with dilute hydrochloric acid to remove its oxide layer; then ultrasonically clean the surface of the iron target twice with deionized water to remove Residual dilute hydrochloric acid, then dry the iron target for use;

[0027] (2) Put the dry iron target in a 50 ml beaker, add 20 ml of graphene-PEG solution with a concentration of 0.5 mg / mL, so that the liquid level above the iron target is 0.5-1.5 cm;

[0028] (3) Start the nanosecond laser, and use focused light with a wavelength of 1064 nanometers to ablate the iron target in (2), where the laser energy, frequency, and action time are 180-250 mJ, 10-15 Hz, 30-40 Minutes; the target was moved every 2...

Embodiment 3

[0031] This embodiment provides a method for synthesizing graphene-PEG-γ-Fe by nanosecond laser ablation in liquid phase 2 o 3 A compound method comprising the steps of:

[0032] (1) Using a block iron target with a purity of 99.9% as a raw material, polish the surface of the target with sandpaper, and ultrasonically clean it with dilute hydrochloric acid to remove its oxide layer; then ultrasonically clean the surface of the iron target twice with deionized water to remove Residual dilute hydrochloric acid, then dry the iron target for use;

[0033] (2) Put the dry iron target in a 50 ml beaker, add 20 ml of graphene-PEG solution with a concentration of 0.8 mg / mL, so that the liquid level above the iron target is 0.5-1.5 cm;

[0034] (3) Start the nanosecond laser, and use focused light with a wavelength of 1064 nanometers to ablate the iron target in (2), where the laser energy, frequency, and action time are 180-250 mJ, 10-15 Hz, 30-40 Minutes; the target was moved every...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com