Anti-fingerprint antibacterial film, and preparation method of hardening liquid

An antibacterial film and anti-fingerprint technology, applied in the field of optical film, can solve the problem of low utilization of sunlight, and achieve the effects of good transparency, prevention of residue and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

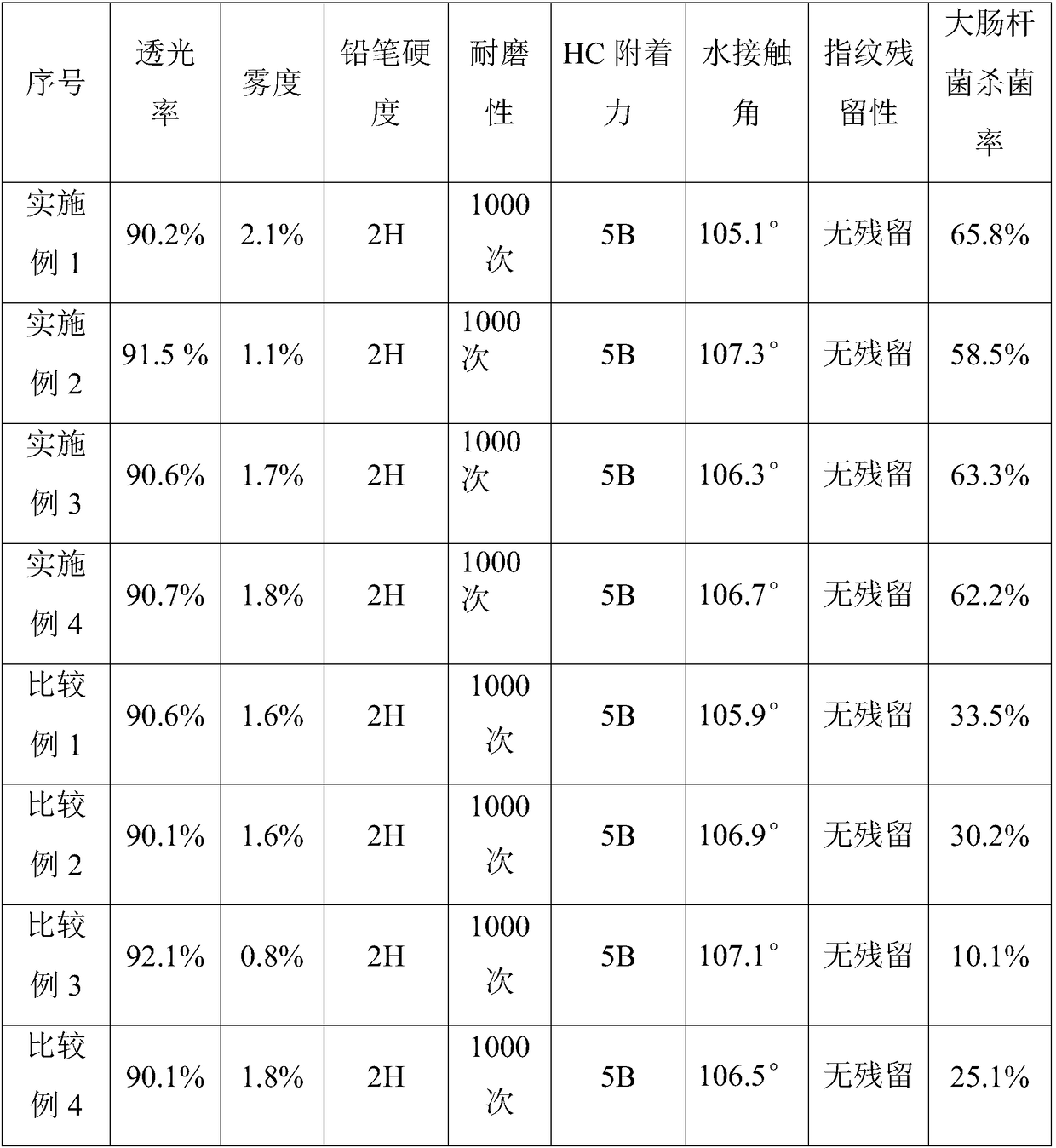

Examples

Embodiment 1

[0027] Coating solution 1: Dissolve 20 parts by weight of anti-fingerprint UV-curable resin MA001 (provided by Lida Chemical) into 72 parts by weight of isopropanol solvent, stir for 30 minutes, and then slowly add 8 parts by weight of titanium by using a dropping funnel. Acid tetrabutyl ester, stirred for 2h to form a mixed solution;

[0028] Coating solution 2: mix 60 parts by weight of isopropanol with 40 parts by weight of ammonia water (provided by Tianjin Hengxing Chemical), and stir for 30 minutes;

[0029] Hardening solution: Slowly add coating solution 2 to coating solution 1 using a dropping funnel, and dilute to a coating solution with a solid content of about 20%. Coat the hardening solution on a PET transparent substrate (Cologne U43R, South Korea) with a thickness of 100 μm, place it in a circulating oven at 100°C for 60 minutes, and then pass a dose of about 600mJ / cm 2 Ultraviolet light irradiation, promptly made an anti-fingerprint antibacterial film.

Embodiment 2

[0031] Coating solution 1: Dissolve 50 parts by weight of anti-fingerprint UV-curable resin MA001 (provided by Lida Chemical) into 48 parts by weight of isopropanol solvent, stir for 30 minutes, and then slowly add 2 parts by weight of titanium Acetate isopropyl ester, stirred for 2h to form a mixed solution;

[0032] Coating Solution 2: Mix 90 parts by weight of isopropanol and 10 parts by weight of ammonia water (provided by Tianjin Hengxing Chemical), and stir for 30 minutes;

[0033] Hardening solution: Slowly add coating solution 2 to coating solution 1 using a dropping funnel, and dilute to a coating solution with a solid content of about 40%. Coat the hardening solution on a PET transparent substrate (Cologne U43R, South Korea) with a thickness of 100 μm, place it in a circulating oven at 100°C for 60 minutes, and then pass a dose of about 600mJ / cm 2 Ultraviolet light irradiation, promptly made an anti-fingerprint antibacterial film.

Embodiment 3

[0035] Coating solution 1: Dissolve 35 parts by weight of anti-fingerprint UV-curable resin MA001 (provided by Lida Chemical) into 59 parts by weight of isopropanol solvent, stir for 30 minutes, and then slowly add 6 parts by weight of titanium Acid tetrabutyl ester, stirred for 2h to form a mixed solution;

[0036] Coating Solution 2: Mix 70 parts by weight of isopropanol and 30 parts by weight of ammonia water (provided by Tianjin Hengxing Chemical), and stir for 30 minutes;

[0037] Hardening solution: Slowly add coating solution 2 to coating solution 1 using a dropping funnel, and dilute to a coating solution with a solid content of about 30%. Coat the hardening solution on a PET transparent substrate (Cologne U43R, South Korea) with a thickness of 100 μm, place it in a circulating oven at 100°C for 60 minutes, and then pass a dose of about 600mJ / cm 2 Ultraviolet light irradiation, promptly made an anti-fingerprint antibacterial film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com