Method for comprehensively extracting saponin and polyphenol from Camellia oleifera Abel. cakes

A comprehensive extraction and camellia oleifera drying technology, applied in chemical instruments and methods, pharmaceutical formulations, steroids, etc., can solve the problems of difficult industrialization, large residual toxic substances, complex process, etc., and achieve convenient solvent recovery and easy operation Simple, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

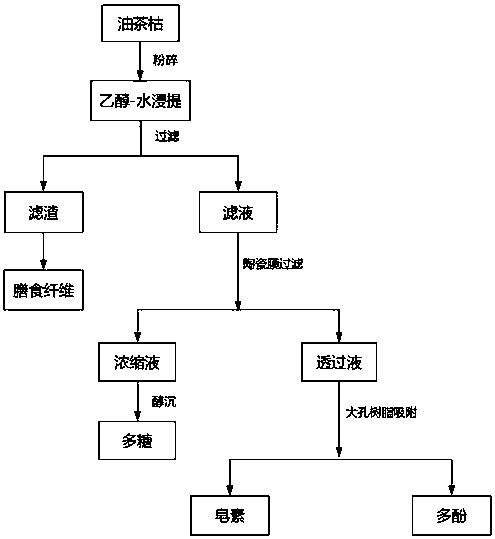

[0031] Such as Figure 1-5 As shown, 0.5 kg of non-defatted Camellia oleifera powder was added to 5 L of 70 % ethanol, continuously extracted at 70 ° C for 3 h, and filtered. Filter the filtrate through a ceramic membrane, add 95% ethanol to the retentate for alcohol precipitation to obtain polysaccharides, and concentrate the permeate under reduced pressure until it has no alcohol smell. The pH of the 0.1% HCl solution concentrate is 4.0, and AB-8 macroporous resin is used for adsorption. The macroporous resin after adsorption was washed with water until the effluent was colorless, then eluted with 0.02% NaOH solution, and the polyphenols were analyzed, then washed with water until the effluent was neutral, and finally the soap was treated with 80% ethanol solution. The element is eluted. The NaOH eluate was collected and adjusted to pH = 5.0 with 0.1% HCl solution, concentrated by nanofiltration membrane, and vacuum-dried to obtain 9.6 g reddish-brown polyphenols with a pu...

Embodiment 2

[0033] Such as Figure 1-5 As shown, 1.0 kg of non-defatted Camellia oleifera powder was added to 12 L of 60% ethanol, continuously extracted at 80°C for 4 h, and filtered. Filter the filtrate through a ceramic membrane, add 95% ethanol to the retentate for alcohol precipitation to obtain polysaccharides, and concentrate the permeate under reduced pressure until it has no alcohol smell. with 0.5% H 2 SO 4 The pH of the solution concentrate is 6, and ADS-21 macroporous resin is used for adsorption. The macroporous resin after adsorption is washed with water until the effluent is colorless, then eluted with 0.03% NaOH solution, and the polyphenols are analyzed, then washed with water until the effluent is neutral, and finally the soap is treated with 90% ethanol solution. The element is eluted. The NaOH eluate was collected and washed with 0.5% H 2 SO 4 Solution Adjust the solution to pH = 4.5, concentrate it with nanofiltration membrane, and use freeze-drying to obtain 20...

Embodiment 3

[0035] Such as Figure 1-5 As shown, 10.0 kg of non-defatted Camellia oleifera powder was added to 150 L of 75% ethanol, continuously extracted at 85°C for 4 h, and filtered. Filter the filtrate through a ceramic membrane, add 95% ethanol to the retentate for alcohol precipitation to obtain polysaccharides, and concentrate the permeate under reduced pressure until it has no alcohol smell. with 1 % H 2 SO 4 The pH of the solution concentrate is 5, and AB-8 macroporous resin is used for adsorption. The macroporous resin after adsorption is washed with water until the effluent is colorless, then eluted with 0.04% NaOH solution, and the polyphenols are analyzed, then washed with water until the effluent is neutral, and finally the soap is treated with 85% ethanol solution. The element is eluted. The NaOH eluate was collected and washed with 1% HO 2 SO 4 Solution Adjust the solution to pH=5.0, concentrate it with nanofiltration membrane, and use spray drying to obtain 198.6 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com