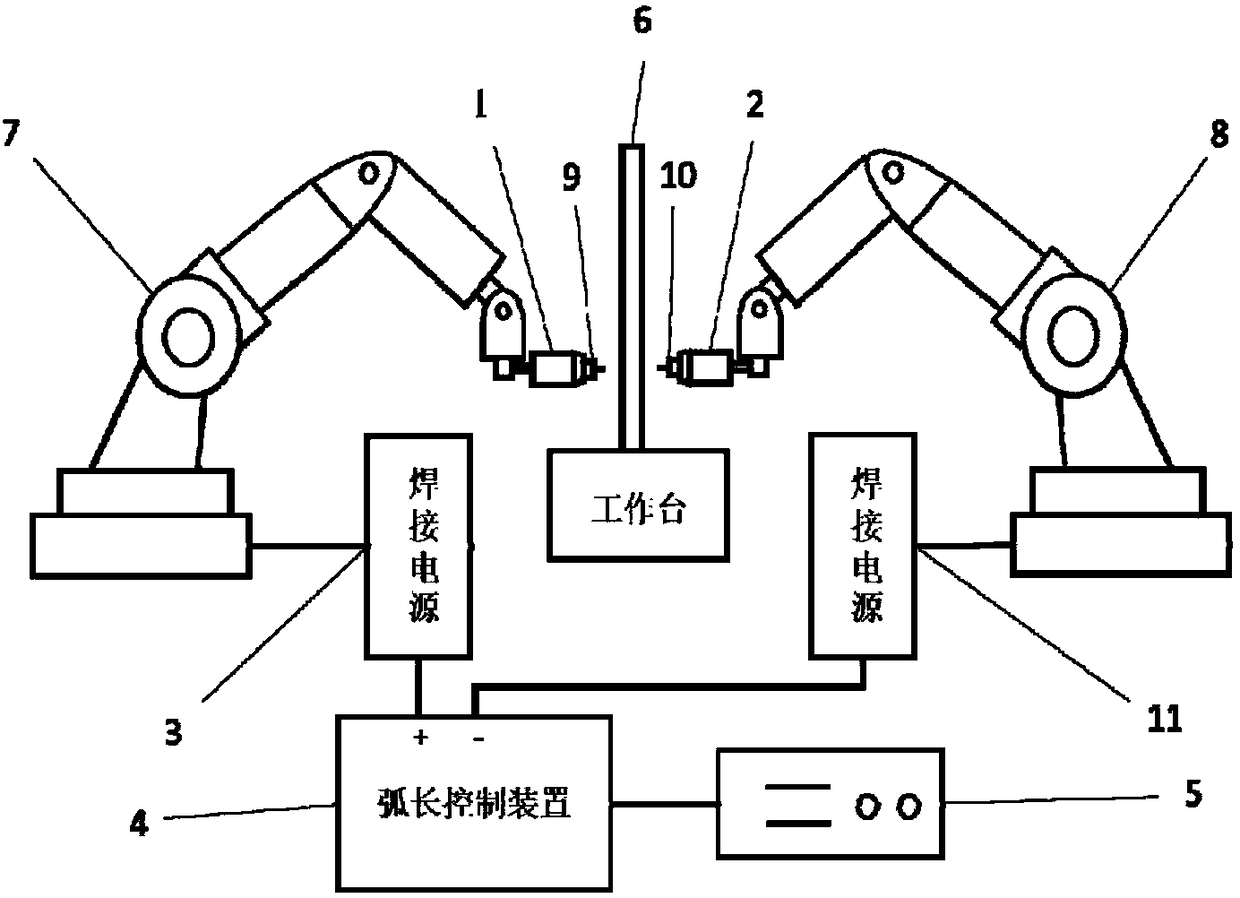

Double-side double-arc vertical welding fusion depth control device and welding method thereof

A control device, double-sided double-arc technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., to achieve the effect of improving efficiency, reducing welding deformation, and reducing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

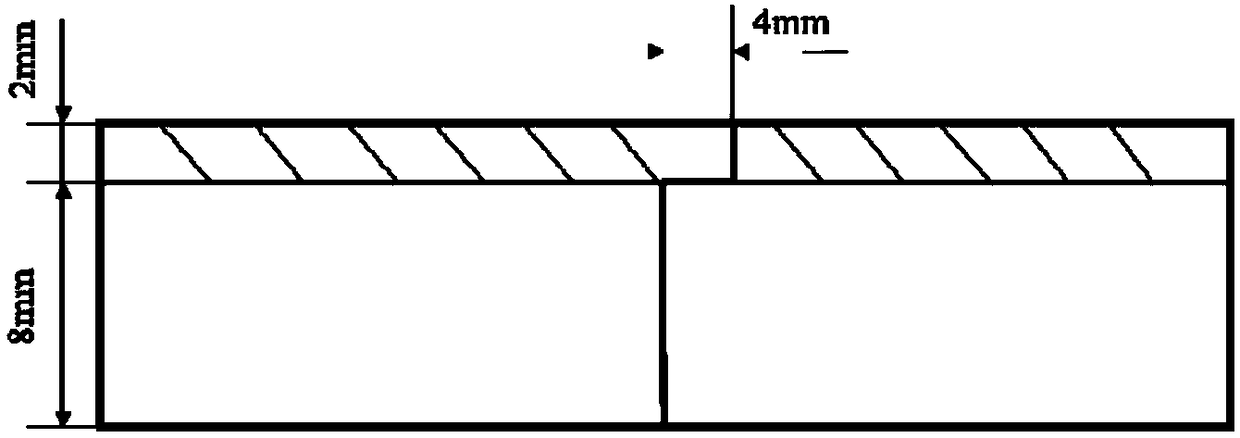

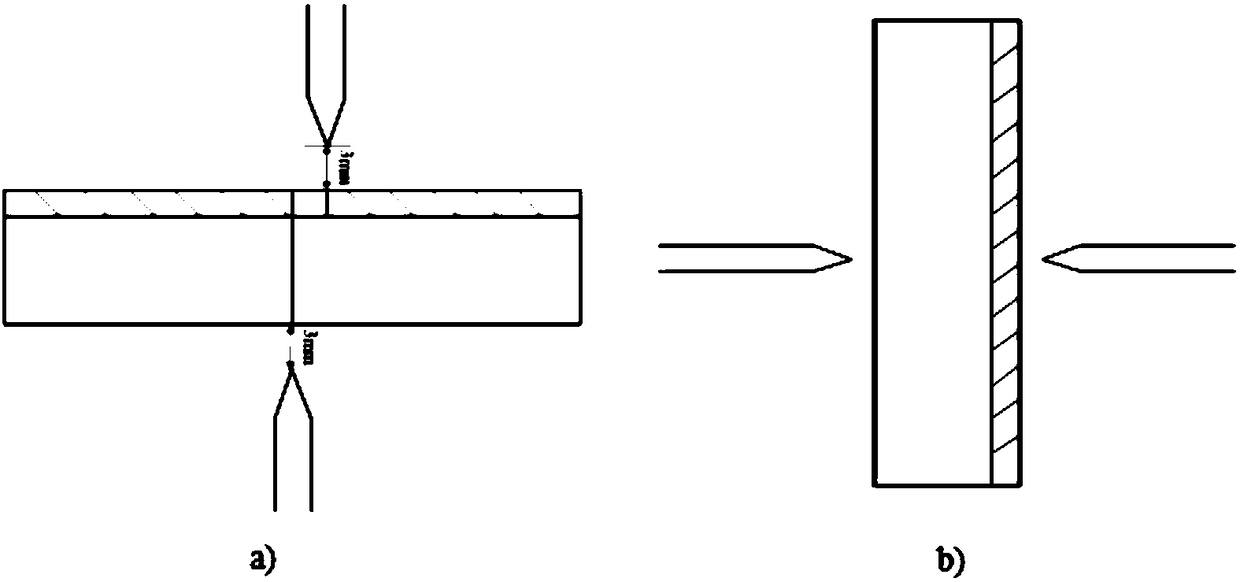

[0051] The 10mm titanium-steel composite plate is butted, the steel is the base layer, the thickness is 8mm, the titanium is the cladding layer, the thickness is 2mm, the groove shape is as follows figure 1, the seams are 4mm apart. The self-fluxing tungsten argon arc welding process is used for welding. The electrode is made of cerium tungsten. The diameter of the tungsten pole is 3.2mm. The distance between the tungsten pole A and the tungsten pole B on both sides is 3mm from the surface of the workpiece. , The gas flow rate on the titanium side is 10L / min, and the gas flow rate on the steel side is 12L / min.

[0052] By querying the relationship model database between penetration depth and voltage, the standard voltage value of penetration 8mm steel is 15V, and that of penetration 2mm titanium plate is 9V. During welding, the voltage detection device obtains the voltage of 11.8V on both sides of the composite board during the arcing stage. The molten pool in the arcing sect...

Embodiment 2

[0054] The 10mm stainless steel-steel composite panels are butted, the steel is the base layer, the thickness is 8mm, the stainless steel is the cladding layer, the thickness is 2mm, the groove shape is as follows figure 1 , the seams are 4mm apart. The self-fluxing tungsten argon arc welding process is used for welding. The electrode is made of cerium tungsten. The diameter of the tungsten pole is 3.2mm. The distance between the tungsten pole A and the tungsten pole B on both sides is 3mm from the surface of the workpiece. The gas flow rate on the stainless steel side is 12L / min, and the gas flow rate on the steel side is 15L / min.

[0055] By querying the relationship model database between penetration depth and voltage, the standard voltage value of penetration 8mm steel is 15V, and that of penetration 2mm stainless steel plate is 8V. During welding, the voltage detection device obtains 11.8V on both sides of the composite plate during the arcing stage. After the welding to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com