Rubber regenerative exhaust gas treatment device

A waste gas treatment device, rubber technology, applied in the direction of gas treatment, chemical/physical process, chemical/physical/physical chemical process, etc., can solve the problem of harmful tail gas pollution of the environment, achieve high combustion efficiency, exhaust gas incineration, and complete combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

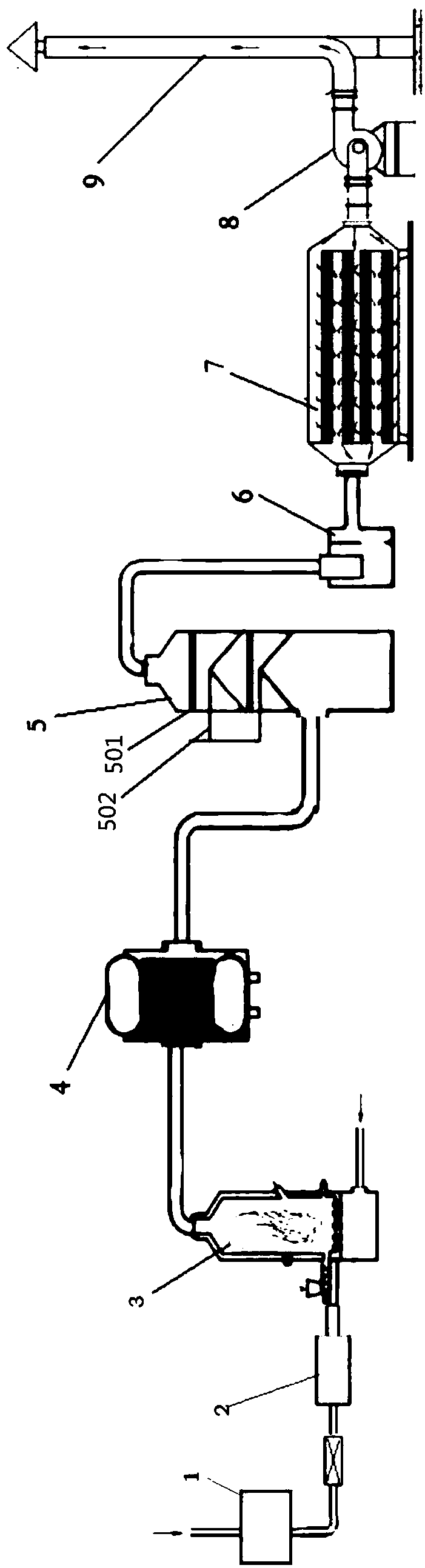

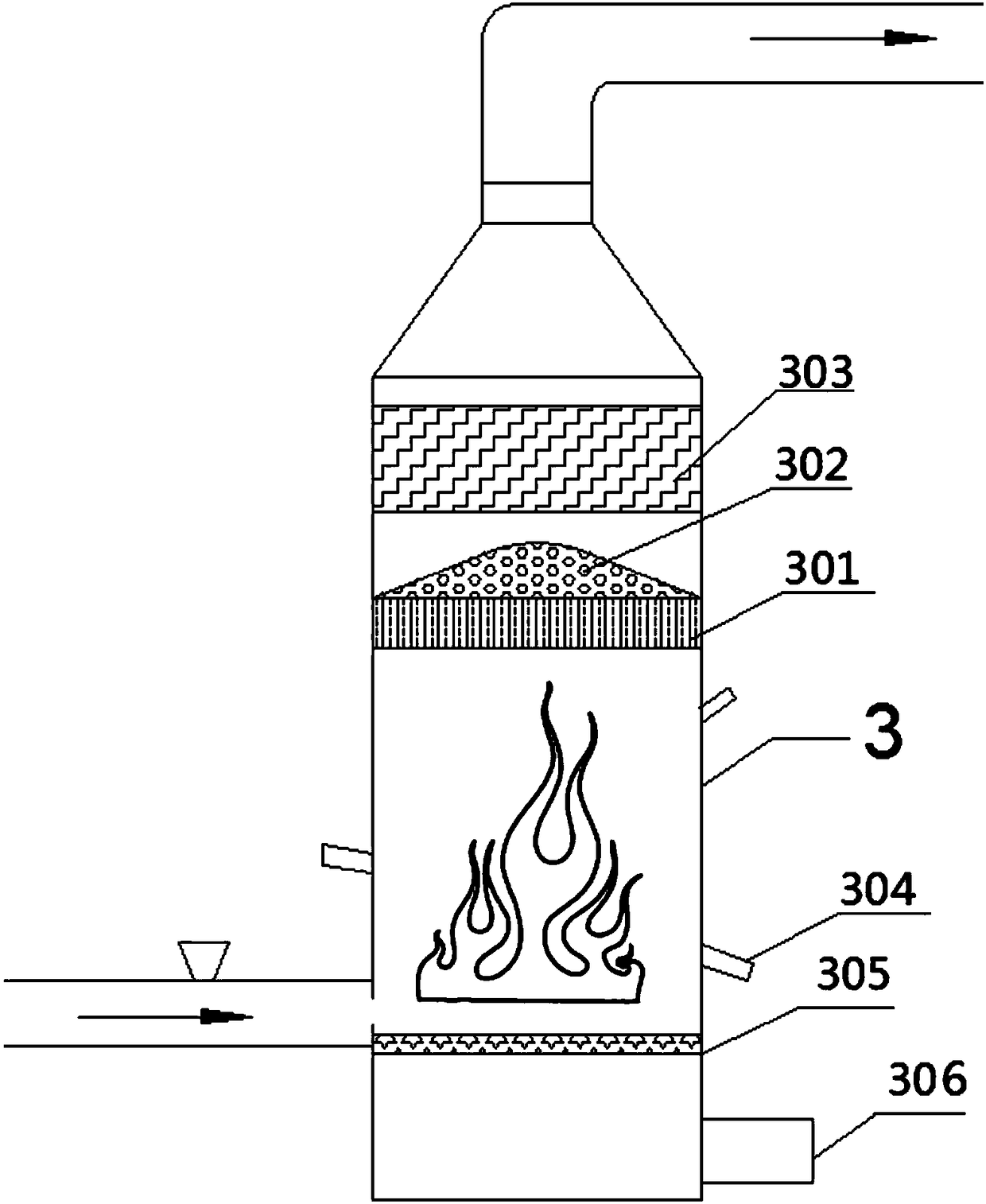

[0037] Such as figure 1 As shown, a rubber regeneration waste gas treatment device is characterized in that it includes an air supply system, an electric control system, and a waste gas filter device 1, a burner 2, an incinerator 3, and a flue gas heat-absorbing cooling tank connected in sequence through pipelines 4. Spray absorption tower 5, water and gas separator 6, dust removal filter device 7, chimney 9; exhaust gas passes through the exhaust gas filter device 1 and then enters the burner 1 through the pipeline, and enters the incinerator 3 for high-temperature incineration; the flue gas pipeline is in the flue gas The air heat absorption cooling tank 4 is curved and coiled inside, and the flue gas heat absorption cooling tank 4 is provided with a cold water inlet and a hot water outlet; the air supply system communicates with the incinerator 3 .

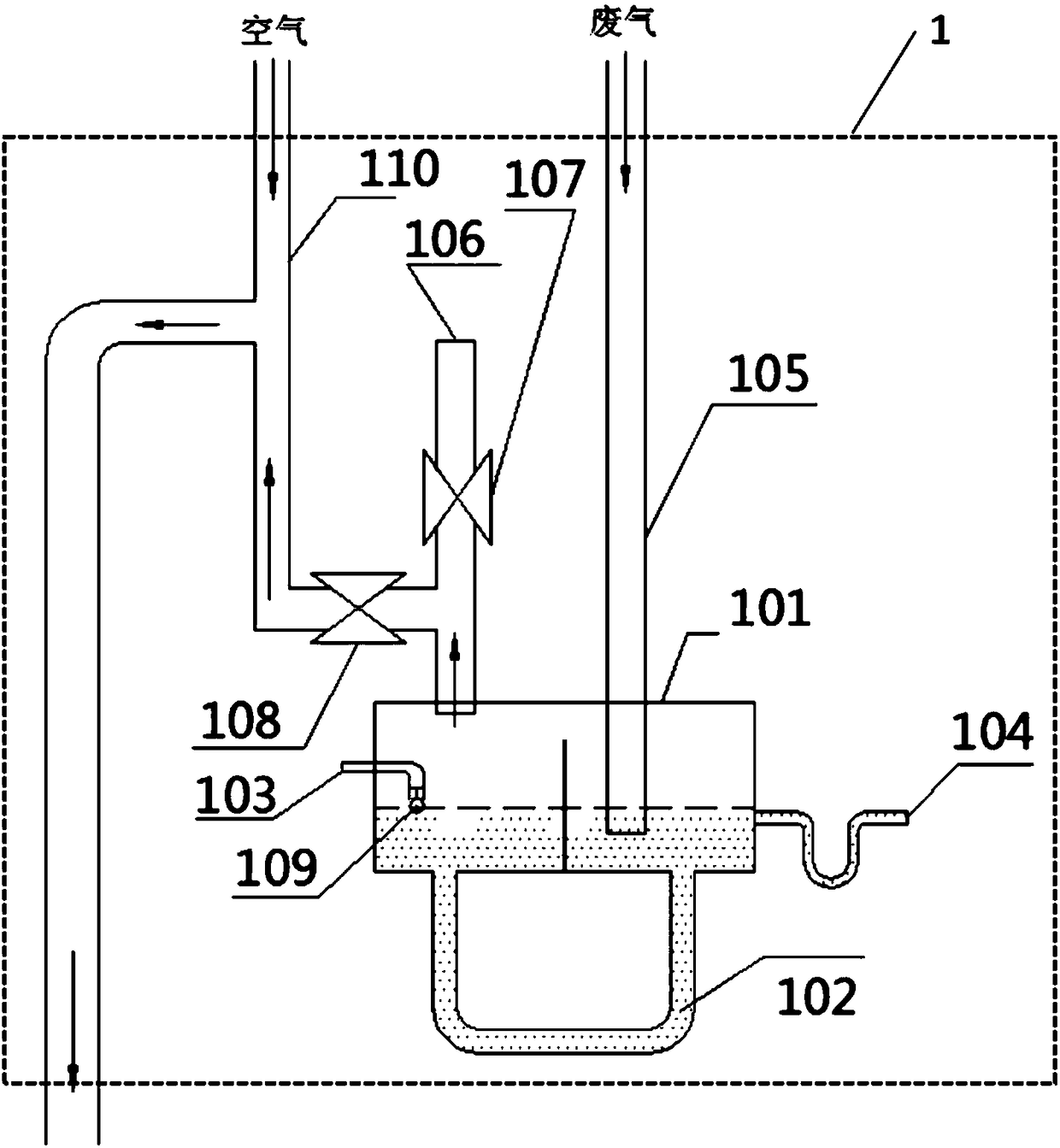

[0038] Such as figure 2 As shown, the waste gas filter device 1 includes a closed water storage tank 101, a U-shaped pipe 1...

Embodiment 2

[0046] Such as figure 1 As shown, a rubber regeneration waste gas treatment device is characterized in that it includes an air supply system, an electric control system, and a waste gas filter device 1, a burner 2, an incinerator 3, and a flue gas heat-absorbing cooling tank connected in sequence through pipelines 4. Spray absorption tower 5, water and gas separator 6, dust removal filter device 7, chimney 9; exhaust gas passes through the exhaust gas filter device 1 and then enters the burner 1 through the pipeline, and enters the incinerator 3 for high-temperature incineration; the flue gas pipeline is in the flue gas The air heat absorption cooling tank 4 is curved and coiled inside, and the flue gas heat absorption cooling tank 4 is provided with a cold water inlet and a hot water outlet; the air supply system communicates with the incinerator 3 .

[0047] In this embodiment, the structures and functions of the exhaust gas filter 1, the burner 2, the incinerator 3, the flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com