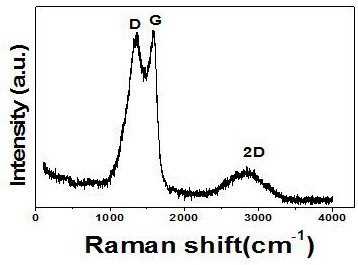

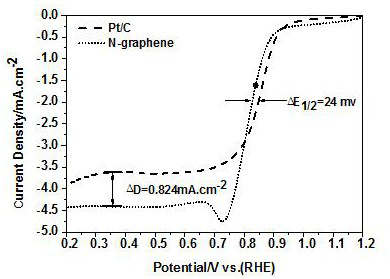

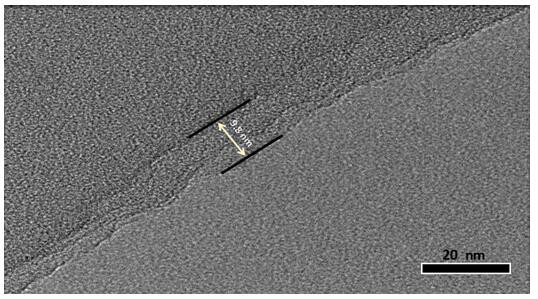

A kind of preparation method and application of nitrogen-doped graphene carbon material

A nitrogen-doped graphene, carbon material technology, applied in graphene, chemical instruments and methods, nano-carbon, etc., can solve the limitation of nitrogen-doped three-dimensional graphene application and development, limited amount of nitrogen doping, and large workload and other problems, to achieve the effect of good chemical stability, good morphology and structure, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: the preparation method of nitrogen-doped graphene carbon material, concrete operations are as follows:

[0045] (1) First divide 250mL of perchloric acid solution with a concentration of 1mol / L into two parts (one part is 200mL and the other part is 50mL), take 10mL of aniline with a density of 1.0217g / mL, according to the transition metal salt and aniline The molar ratio is 1:6. Weigh 4.9378g of ferric chloride hexahydrate and add it to the above 200mL perchloric acid solution and stir until it is completely dissolved, and then feed it for 30minN 2 , to remove dissolved oxygen in the solution to obtain solution A;

[0046] (2) Add 10mL of aniline with a density of 1.0217g / mL to solution A at 23°C, and sonicate for 30min until complete reaction to obtain aniline salt solution;

[0047] (3) Add 10mL of hydrogen peroxide to another 50mL of perchloric acid solution, stir for 5min to make it evenly mixed, and then inject 30minN 2 To remove dissolved oxygen i...

Embodiment 2

[0058] Example 2: The preparation method of the nitrogen-doped graphene carbon material in this example is the same as that in Example 1, except that it is washed three times with deionized water during suction filtration in step (5).

[0059] Figure 7 It is the nitrogen-doped graphene carbon material prepared in embodiment 1 and embodiment 2 in 0.1M saturated KOH solution O 2 Comparison of CV curves under atmosphere, Figure 7 It shows that the area of the CV curve of the precursor after washing with water is not as large as that without washing.

Embodiment 3

[0060] Example 3: The preparation method of the nitrogen-doped graphene carbon material in this example is the same as in Example 1, except that in step (5), it is washed 3 times with absolute ethanol with a mass fraction of 95%.

[0061] Figure 8 It is the nitrogen-doped graphene carbon material prepared in embodiment 1, embodiment 2 and embodiment 3 in 0.1M saturated KOH solution O 2 Comparison of LSV curves in atmosphere, Figure 8 It shows that the washing method of the precursor has a certain influence on the oxygen reduction reaction activity of this nitrogen-doped graphene carbon material, and its activity is unwashed>alcohol washed>water washed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com