Magnetic microsphere and application thereof in hair detection

A magnetic microsphere and magnetic separation technology, applied in the field of chemical detection, can solve the problems of large operator influence, large consumption of reagents, cumbersome and time-consuming steps, etc., and achieve less consumption of organic solvents, reduce the influence of human factors, and be environmentally friendly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

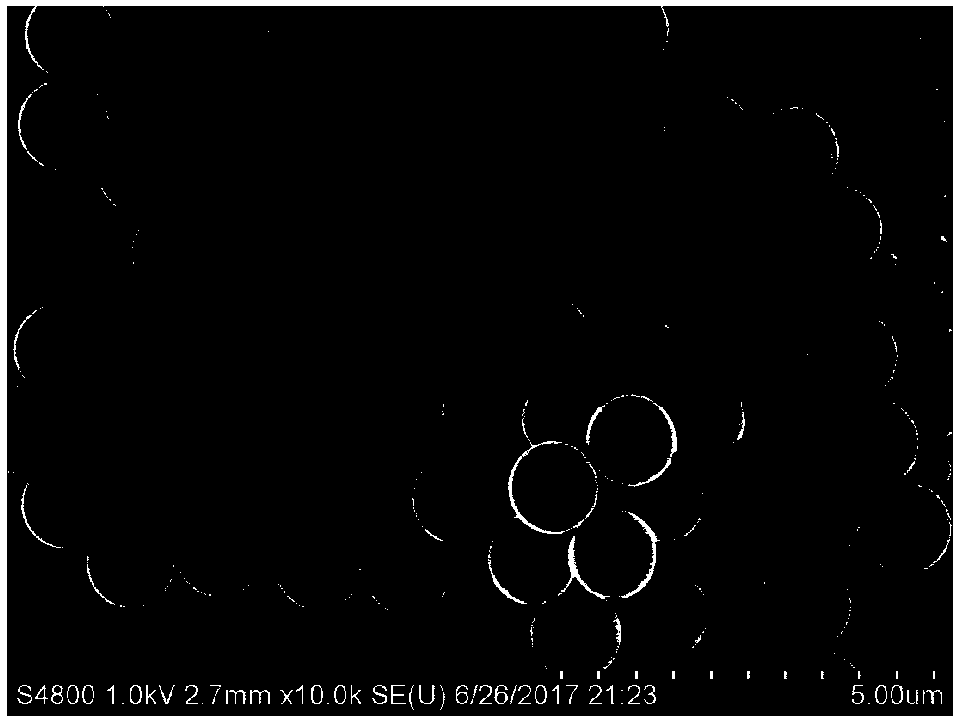

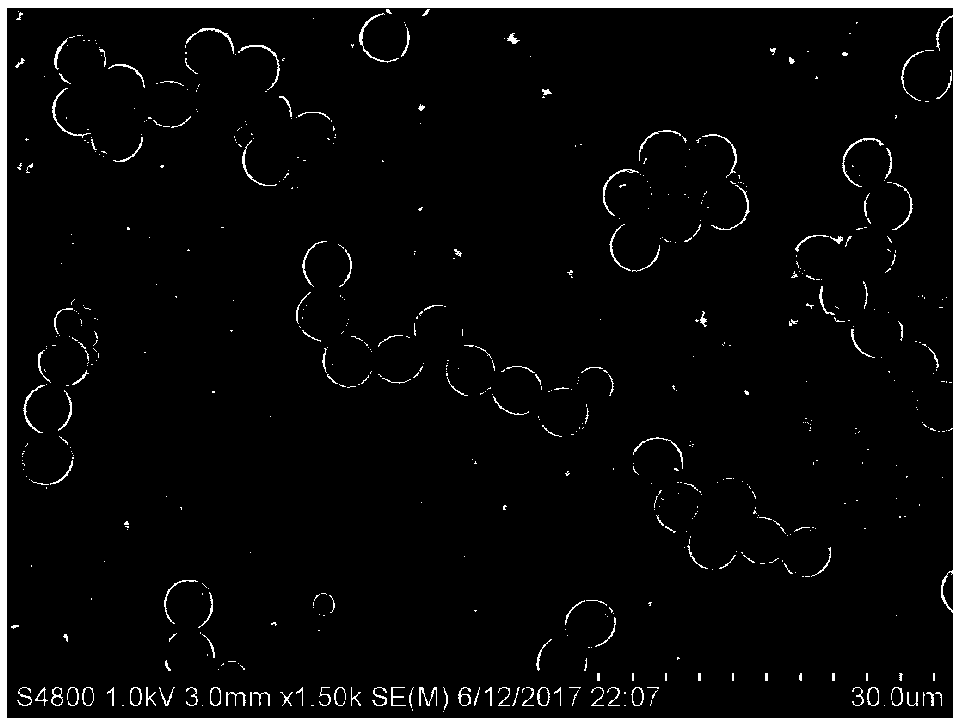

[0018] This embodiment specifically includes the following steps: disperse 1.5g of ferrous chloride tetrahydrate and 3g of ferric chloride hexahydrate into a mixture of 200mL of deoxygenated water and 20mL of ethylene glycol, add 2g of polyethylene glycol 300 in Stir mechanically under nitrogen atmosphere for 30 minutes, then add 0.2g poly(4-styrenesulfonic acid-copolymerization-maleic acid) sodium salt (4-styrenesulfonic acid: maleic acid (molar ratio 1:1)), continue The reaction was stirred mechanically for 30 minutes, 30 mL of concentrated ammonia solution was added, and the temperature of the mixed solution was raised to 80° C. to continue the reaction for 1 hour. Gained black precipitate was washed 5 times with deionization, washed twice with ethanol, and finally dispersed in deionized water to prepare a 100 mg / mL colloidal dispersion to prepare 12nm polyethylene glycol 300 and PSSMA co-stabilized tetroxide Triferro colloidal particles.

Embodiment 2

[0020] This embodiment specifically includes the following steps: disperse 2g of ferrous chloride tetrahydrate and 3.5g of ferric chloride hexahydrate into a mixture of 200mL of deoxygenated water and 20mL of ethylene glycol, add 3g of polyethylene glycol 800 in Stir mechanically under nitrogen atmosphere for 30 minutes, then add 0.3g poly(4-styrenesulfonic acid-copolymerization-maleic acid) sodium salt (4-styrenesulfonic acid: maleic acid (molar ratio 1:1)), continue The reaction was stirred mechanically for 30 minutes, 30 mL of concentrated ammonia solution was added, and the temperature of the mixed solution was raised to 80° C. to continue the reaction for 1 hour. Gained black precipitate was washed 5 times with deionization, washed twice with ethanol, and finally dispersed in deionized water to prepare a 100 mg / mL colloidal dispersion to prepare 9nm polyethylene glycol 800 and PSSMA co-stabilized tetroxide Triferro colloidal particles.

Embodiment 3

[0022] This embodiment specifically includes the following steps: disperse 2 g of ferrous chloride tetrahydrate and 4.5 g of ferric chloride hexahydrate into a mixture of 200 mL of deoxygenated water and 20 mL of ethylene glycol, and add 4.5 g of polyethylene glycol 200 Under nitrogen atmosphere, mechanically stirred for 30 minutes, then added 0.4g poly(4-styrenesulfonic acid-copolymerization-maleic acid) sodium salt (4-styrenesulfonic acid: maleic acid (molar ratio 1:1)), Continue the mechanical stirring reaction for 30 minutes, add 30 mL of concentrated ammonia solution, and raise the temperature of the mixed solution to 80° C. to continue the reaction for 1 hour. Gained black precipitate was washed 5 times with deionization, washed twice with ethanol, and finally dispersed in deionized water to prepare a 100mg / mL colloidal dispersion to prepare 7nm polyethylene glycol 2000 and PSSMA co-stabilized tetroxide Triferro colloidal particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com