Spun-bonding dual-component PP (Propene Polymer)/PE (Polyethylene) hot-air reinforced non-woven material

A non-woven material and two-component technology, applied in the field of non-woven fabrics, can solve problems such as easy crystallization and dyeing difficulties, and achieve the effects of good wearing performance, cost reduction and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

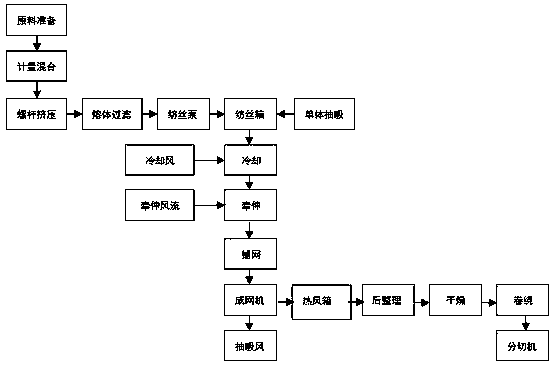

Image

Examples

Embodiment 1

[0044] Using the above technological process, equipment and technical measures, etc., a spunbonded two-component PP / PE hot air reinforced nonwoven material has been developed, in which it is composed of polypropylene PP and polyethylene PE. The process parameters for processing spunbond two-component PP / PE spunbonded fiber web are: spunbond process parameters are, screw temperature (°C) is 1 zone: 206; 2 zone: 227; 3 zone: 230; 4 zone : 237; District 5: 260; District 6: 239; District 7: 240. Chamber temperature (°C): 236. Cooling air temperature (°C): 20. Metering pump speed (rpm): 14.5. Pre-filtration pressure (Mpa): 5.98. Filtered pressure (Mpa): 5. Masterbatch speed 1 (rpm): 7, masterbatch speed 2 (rpm): 12.8, upper roll temperature (°C): 138, lower roll temperature (°C): 134, box pressure (Mpa): 0.92, roll Pressure (Mpa): 6, melt temperature (°C): 221, suction fan speed (rpm): 449, side blower speed (rpm): 500, mill speed (m / min): 94, winding speed (m / min): 105, web...

Embodiment 2

[0046] Using the above technological process, equipment and technical measures, etc., a spunbonded two-component PP / PE hot air reinforced nonwoven material has been developed, in which it is composed of polypropylene PP and polyethylene PE. The process parameters for processing spunbond two-component PP / PE spunbonded fiber web are: spunbond process parameters are, screw temperature (°C) is 1 zone: 229.5; 2 zone: 235; 3 zone: 242; 4 zone : 247; District 5: 253; District 6: 249; District 7: 249. Chamber temperature (°C): 237. Cooling air temperature (°C): 24. Metering pump speed (rpm): 15.5. Pre-filtration pressure (Mpa): 5.08. Filtered pressure (Mpa): 5.1. Masterbatch speed 1 (rpm): 7, masterbatch speed 2 (rpm): 12.9, upper roll temperature (°C): 140, lower roll temperature (°C): 136, box pressure (Mpa): 0.62, roll Pressure (Mpa): 6.4, melt temperature (°C): 225, suction fan speed (rpm): 605, side blower speed (rpm): 603, mill speed (m / min): 38, winding speed (m / min): 43...

Embodiment 3

[0048] Using the above technological process, equipment and technical measures, etc., a spunbonded two-component PP / PE hot air reinforced nonwoven material has been developed, in which it is composed of polypropylene PP and polyethylene PE. The process parameters for processing spunbond two-component PP / PE spunbonded fiber web are: spunbond process parameters are, screw temperature (°C) is 1 zone: 227.5; 2 zone: 237; 3 zone: 243; 4 zone : 246; District 5: 254; District 6: 250; District 7: 250. Chamber temperature (°C): 236. Cooling air temperature (°C): 23. Metering pump speed (rpm): 20.5. Pre-filtration pressure (Mpa): 6.68. Filtered pressure (Mpa): 5.3. Masterbatch speed 1 (rpm): 7, masterbatch speed 2 (rpm): 12.6, upper roll temperature (°C): 142, lower roll temperature (°C): 137, box pressure (Mpa): 0.78, roll Pressure (Mpa): 6.6, Melt temperature (°C): 226, Suction fan speed (rpm): 655, Side blower speed (rpm): 653, Mill speed (m / min): 40, Winding speed (m / min): 44...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com