Degradable corrosion-resistant magnesium alloy for vascular stents, and preparation method of degradable corrosion-resistant magnesium alloy

A vascular stent and magnesium alloy technology, applied in the field of medical alloys, can solve problems such as vascular wall irritation, vascular stenosis, increased probability of vascular intimal hyperplasia, etc., to avoid damage to human health, excellent mechanical properties and corrosion resistance, important Effects of social and economic significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

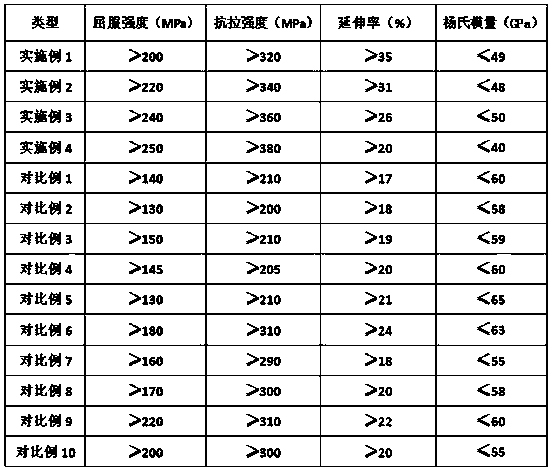

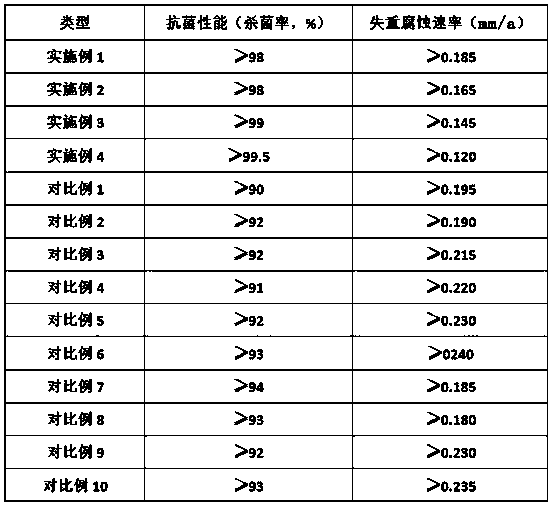

Examples

Embodiment 1

[0040] A degradable and corrosion-resistant magnesium alloy for a blood vessel stent is characterized in that: it is composed of the following elements by mass percentage: Zn 9.5, Gd 2.1, Nd 1.6, Ca 1.5, Y 1.2, Mn 0.7, Zr 0.5, Sn 0.5, Si 0.2 , carbon nanotubes 0.1, Zn / Y 7.92, Zn / Ca 6.33, and the rest are Mg and inevitable impurity elements.

[0041] The preparation method of the degradable corrosion-resistant magnesium alloy for the blood vessel stent is characterized in that:

[0042] (1) Selection of raw materials

[0043] Mg ingot with a purity of 99.99%, Zn ingot with a purity of 99.99%, Mg-Zn master alloy with Zn mass ratio of 52wt%, Mg-Nd master alloy with Nd mass ratio of 19-20wt%, Gd mass ratio of 25% Mg-Gd master alloy, Mg-Zr master alloy whose mass ratio of Y accounts for Mg-Y master alloy, and Mg-Zr master alloy whose mass ratio of Zr accounts for 25%, other required elements are in the form of master alloy or element, and carbon nanotubes are in accordance with th...

Embodiment 2

[0051] A degradable corrosion-resistant magnesium alloy for a blood vessel stent is characterized in that: it is composed of the following elements in mass percentage: Zn9.7, Gd2.2, Nd1.65, Ca1.6, Y1.2, Mn0.7, Zr0.5, Sn0.5, Si 0.2, carbon nanotubes 0.12, Zn / Y 8.08, Zn / Ca 6.06, and the rest are Mg and inevitable impurity elements.

[0052] The preparation method of the degradable corrosion-resistant magnesium alloy for the blood vessel stent is characterized in that:

[0053] (1) Selection of raw materials

[0054]Mg ingot with a purity of 99.99%, Zn ingot with a purity of 99.99%, Mg-Zn master alloy with Zn mass ratio of 52wt%, Mg-Nd master alloy with Nd mass ratio of 19-20wt%, Gd mass ratio of 25% Mg-Gd master alloy, Mg-Zr master alloy whose mass ratio of Y accounts for Mg-Y master alloy, and Mg-Zr master alloy whose mass ratio of Zr accounts for 25%, other required elements are in the form of master alloy or element, and carbon nanotubes are in accordance with the target mag...

Embodiment 3

[0062] A degradable and corrosion-resistant magnesium alloy for a blood vessel stent is characterized in that: it is composed of the following elements by mass percentage: Zn9.9, Gd2.4, Nd1.75, Ca2, Y1.3, Mn0.9, Zr0.55, Sn0.7, Si 0.3, carbon nanotubes 0.18, Zn / Y7.62, Zn / Ca 4.95, and the rest are Mg and inevitable impurity elements.

[0063] The preparation method of the degradable corrosion-resistant magnesium alloy for the blood vessel stent is characterized in that:

[0064] (1) Selection of raw materials

[0065] Mg ingot with a purity of 99.99%, Zn ingot with a purity of 99.99%, Mg-Zn master alloy with Zn mass ratio of 52wt%, Mg-Nd master alloy with Nd mass ratio of 19-20wt%, Gd mass ratio of 25% Mg-Gd master alloy, Mg-Zr master alloy whose mass ratio of Y accounts for Mg-Y master alloy, and Mg-Zr master alloy whose mass ratio of Zr accounts for 25%, other required elements are in the form of master alloy or element, and carbon nanotubes are in accordance with the targe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com