Water-resistant pressure-sensitive adhesive and preparation process thereof

A pressure-sensitive adhesive and preparation technology, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve the problems of residue and small peeling, and achieve improved viscosity, good initial tack, heat resistance and The effect of improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

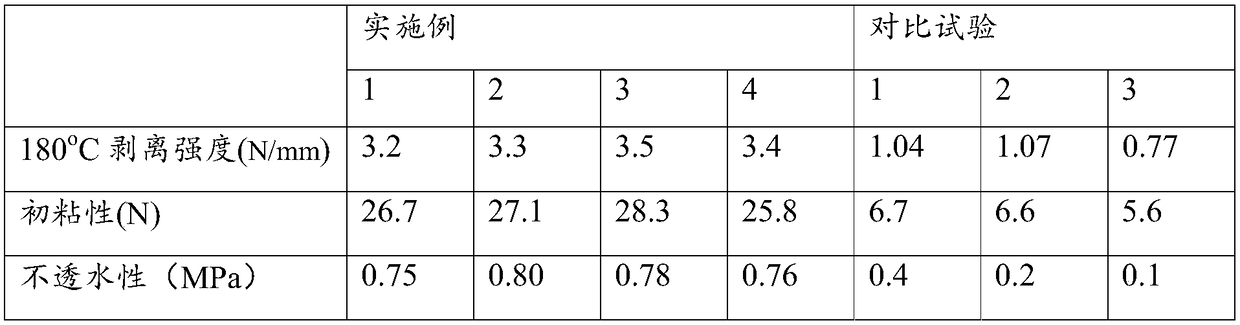

Examples

Embodiment 1

[0023] A waterproof pressure-sensitive adhesive, the pressure-sensitive adhesive comprises the following mass components of raw materials: 60 parts of SIS; 15 parts of SBS; 50 parts of naphthenic oil; 30 parts of C5 petroleum resin; 80 parts of filler; 1 part of oxidant; 1 part of isobutyl triethoxy silicon; the mass components of the pressure-sensitive adhesive also include: 30 parts of styrene-butadiene rubber; 20 parts of polyisobutylene rubber;

[0024] The filler is at least one of zinc oxide, marble powder, porcelain powder and glass powder; the antioxidant is zinc ethylphenyl dithiocarbamate, N, N-dibutylcarbamate zinc and at least one of 2,6-di-tert-butyl-p-cresol.

[0025] A preparation process of a waterproof pressure-sensitive adhesive, comprising the following steps:

[0026] (1) Take SIS, SBS, naphthenic oil, C5 petroleum resin, fillers, antioxidants, isobutyl triethoxy silicon according to the mass components, and add them to the reaction kettle, blow nitrogen, ...

Embodiment 2

[0030] A waterproof pressure-sensitive adhesive, the pressure-sensitive adhesive comprises the following raw materials of mass components: 100 parts of SIS; 20 parts of SBS; 80 parts of naphthenic oil; 60 parts of C5 petroleum resin; 100 parts of filler; 1.5 parts of oxidant; 3 parts of isobutyl triethoxy silicon; the mass components of the pressure-sensitive adhesive also include: 50 parts of styrene-butadiene rubber; 25 parts of polyisobutylene rubber; the fillers are zinc oxide, marble powder , at least one of porcelain powder and glass powder; the antioxidant is zinc ethylphenyl dithiocarbamate, N, N-dibutylzinc dithiocarbamate and 2,6-di-tert-butyl at least one of p-cresol.

[0031] A preparation process of a waterproof pressure-sensitive adhesive, comprising the following steps:

[0032] (1) Take SIS, SBS, naphthenic oil, C5 petroleum resin, fillers, antioxidants, isobutyl triethoxy silicon according to the mass components, and add them to the reaction kettle, blow nitr...

Embodiment 3

[0036] A waterproof pressure-sensitive adhesive, the pressure-sensitive adhesive comprises the following mass components of raw materials: 90 parts of SIS; 18 parts of SBS; 70 parts of naphthenic oil; 70 parts of C5 petroleum resin; 90 parts of filler; 2 parts of oxidant; 2 parts of isobutyl triethoxy silicon; the mass components of the pressure-sensitive adhesive also include: 40 parts of styrene-butadiene rubber; 25 parts of polyisobutylene rubber; the filler is zinc oxide, marble powder , at least one of porcelain powder and glass powder; the antioxidant is zinc ethylphenyl dithiocarbamate, N, N-dibutylzinc dithiocarbamate and 2,6-di-tert-butyl at least one of p-cresol.

[0037] A preparation process of a waterproof pressure-sensitive adhesive, comprising the following steps:

[0038] (1) Take SIS, SBS, naphthenic oil, C5 petroleum resin, fillers, antioxidants, isobutyl triethoxy silicon according to the mass components, and add them to the reaction kettle, blow nitrogen, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com