Mytilopsis surface modified magnesium alloy and preparation method and application thereof

A technology of surface modification and magnesium alloy, which is applied in pharmaceutical formula, metal material coating process, prosthesis, etc., can solve the problems of poor biocompatibility and poor corrosion resistance, achieve strong affinity and improve corrosion resistance , Improving the effect of corrosion resistance and cytocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Use 600# and 1000# SiC sandpaper to remove the surface oxide layer of the AZ31 magnesium alloy sheet with a thickness of 2mm and a length and width of 10mm, and then use alcohol to clean it ultrasonically. Then carry out hydrothermal treatment, the hydrothermal solution is 50ml of 0.02M aluminum nitrate solution, and use sodium hydroxide or potassium hydroxide to adjust its pH value to 12.8, and finally react at 120°C for 12h. The resulting sample was labeled LDH.

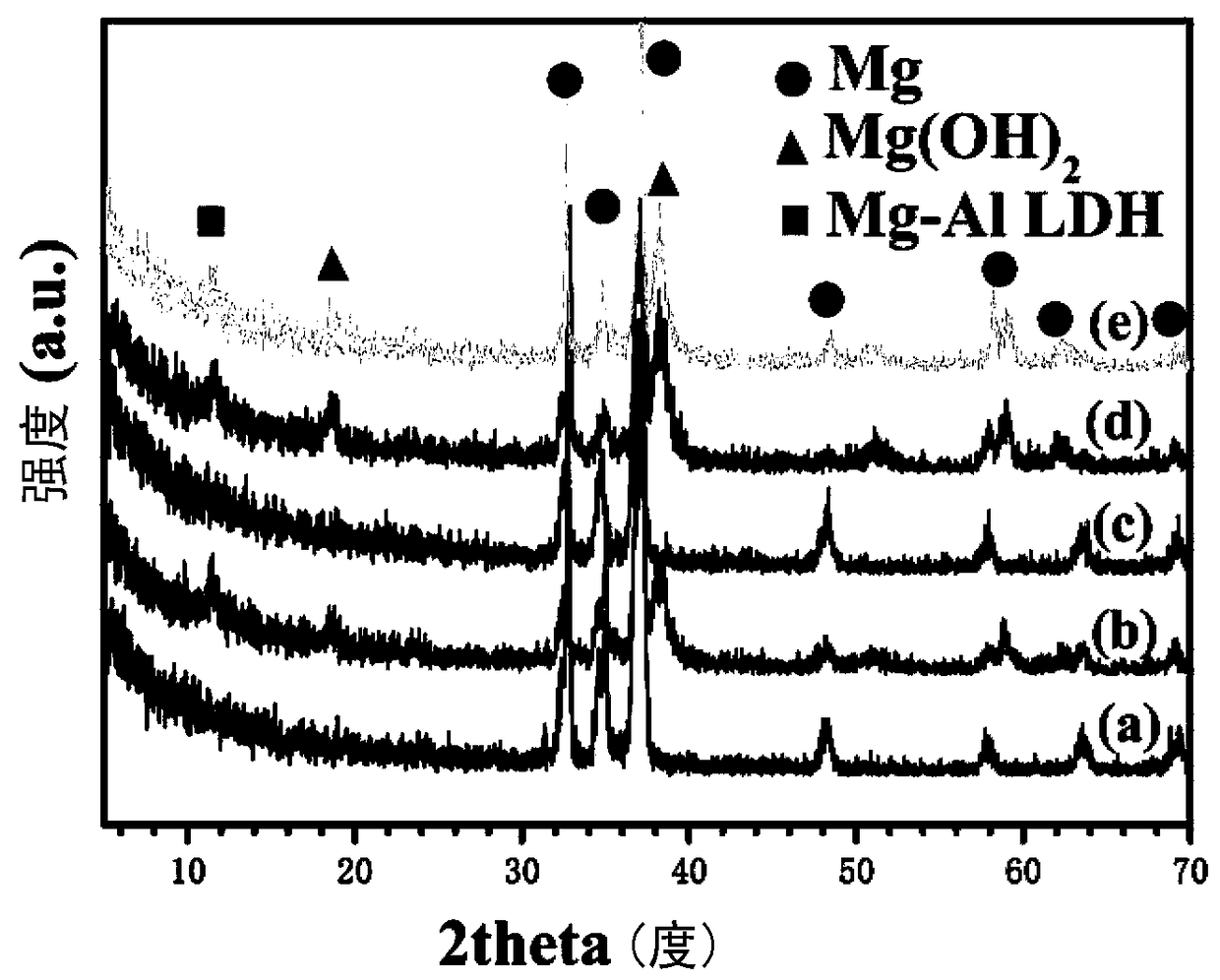

[0044] figure 1 (b) is the scanning electron micrograph and optical picture of the surface morphology of the magnesium alloy obtained through the modification treatment in this embodiment. It can be seen from the figure that the surface of the LDH sample is a layer of dense nanosheets, and its color under natural light is light yellow. figure 2 (b) in this example shows the XRD pattern of the sample surface after the treatment of this embodiment. It can be seen from the figure that the structure of the LD...

Embodiment 2

[0046] Use 600# and 1000# SiC sandpaper to remove the surface oxide layer of the AZ31 magnesium alloy sheet with a thickness of 2mm and a length and width of 10mm, and then use alcohol to clean it ultrasonically. Afterwards, the magnesium alloy sheet was placed in 2 mg / mL dopamine hydrochloride solution, and its pH value was adjusted to 8.5 by 0.1 M sodium hydroxide, and reacted at 37° C. for 12 hours. The resulting sample was labeled PDA.

[0047] figure 1 (c) is the scanning electron micrograph and optical picture of the surface morphology of the magnesium alloy obtained through the modification treatment of this embodiment. It can be seen from the figure that due to the corrosion during the sample preparation process, a large number of cracks appeared on the surface of the PDA sample, and its color under natural light was dark yellow, indicating that polydopamine was generated on the surface. figure 2 (c) in the present embodiment provides the XRD pattern of the surface ...

Embodiment 3

[0049] The sample obtained from the treatment in Example 1 was placed in 2 mg / mL dopamine hydrochloride solution, and its pH value was adjusted to 8.5 with 0.1 M sodium hydroxide, and kept at 37° C. for 12 hours. The resulting sample is labeled L / P.

[0050] figure 1 (d) is the scanning electron micrograph and optical picture of the surface morphology of the magnesium alloy obtained through the modification treatment of this embodiment. It can be seen from the figure that the surface of the L / P sample is a layer of dense nanosheets, and its color under natural light is dark yellow. This shows that in the process of this embodiment, the original morphology of the sample surface will not be changed, but its optical color is brighter, indicating that polydopamine is generated on the surface of the material. figure 2 (d) among has provided the XRD pattern of sample surface after present embodiment treatment, can find out from figure, the structure of L / P sample surface is the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com