Preparation method of gold-copper sulfide nano material with hollow core-shell structure and application thereof

A technology of nanomaterials and core-shell structure, applied in the field of nanomaterials, can solve the problems of low photothermal efficiency of copper sulfide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention provides a method for preparing a gold-copper sulfide nanomaterial with a hollow core-shell structure, comprising the following steps:

[0042] a) cetyltrimethylammonium bromide, chloroauric acid and sodium borohydride are mixed and reacted to obtain a gold seed solution;

[0043] b) mixing cetyltrimethylammonium bromide, silver nitrate, chloroauric acid, ascorbic acid and gold seed solution, and standing to grow to obtain gold core nanomaterials;

[0044] c) mixing and reacting polyvinylpyrrolidone, water, copper chloride and gold core nanomaterials to obtain a first reaction product;

[0045] d) reacting the first reaction product with sodium hydroxide to obtain a second reaction product;

[0046] e) reacting the second reaction product with hydroxylamine hydrochloride to obtain a third reaction product;

[0047] f) reacting the third reaction product with sodium sulfide, centrifuging, washing and drying the obtained precipitate to obtain a gold-copper...

Embodiment 1

[0085] (1) Gold seed solution synthesis, 5mL 0.2mol / L cetyltrimethylammonium bromide and 5mL 0.5mmol / L chloroauric acid solution were mixed and stirred for 2 minutes, and 0.6mL 0..01mol / L sodium borohydride was added The solution was vigorously stirred for 2 minutes, then stood at 30°C for 30 minutes;

[0086] (2) Gold nanomaterial growth solution, add 0.3mL4mmol / L silver nitrate solution in 5mL 0.2mol / L cetyltrimethylammonium bromide solution, then add 5mL 1mmol / L chloroauric acid solution and stir slowly for 5 Minutes, add 70 μL 78.8mmol / L ascorbic acid solution, and finally add 70 μL seed solution, let it stand at 30°C for 12 hours to obtain a gold core nano solution;

[0087] (3) After adding 0.2g polyvinylpyrrolidone (K-30) into 20mL water and stirring to dissolve, add 1mL0.2mol / L copper chloride solution and stir for 2 minutes, then add 0.5mL 5μg / mL gold core nanomaterial solution and stir for 5 minute;

[0088] (4) Add 0.3mL 2mol / L sodium hydroxide solution to the abo...

Embodiment 2

[0100] The difference from Example 1 is that 3 mL of 5 μg / mL gold core nanomaterial solution is added in step (3). The resulting product is referred to as gold-copper sulfide (2).

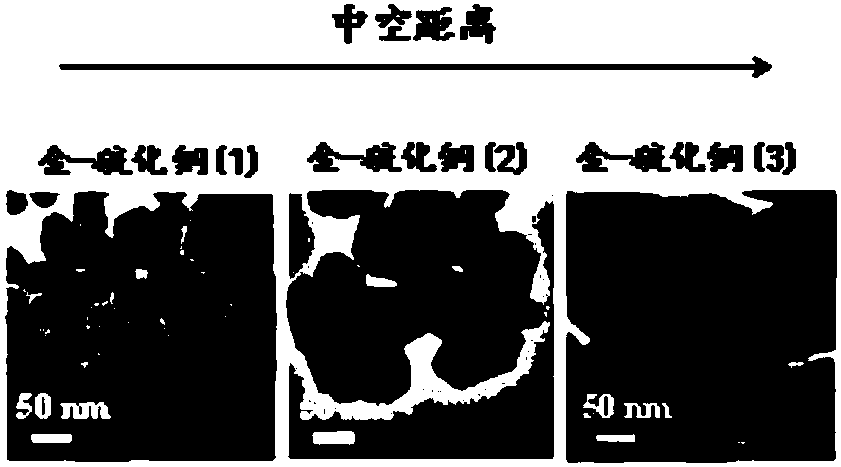

[0101] from image 3 It can be seen that the gold-copper sulfide nanoparticles with a hollow core-shell structure prepared in Example 2 have a hollow distance of 17.5 nm, and the hollow structure is very obvious, and the particle size is uniform.

[0102] The ultraviolet-visible-near-infrared absorption spectrum test result of the gold-copper sulfide nanomaterial prepared in embodiment 2 is shown in Figure 4 .

[0103] The photothermal heating curve of the gold-copper sulfide nanomaterial prepared in embodiment 2 is shown in Figure 5 .

[0104] The free radical generation curve figure of the gold-copper sulfide nanomaterial prepared in embodiment 2 is shown in Image 6 .

[0105] The biosafety evaluation figure of the gold-copper sulfide nanomaterial prepared in embodiment 2 is shown in F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com