Metal demolding agent

A release agent, metal technology, applied in the directions of additives, petroleum industry, lubricating compositions, etc., can solve the problems of poor heat resistance, poor release performance of metal release agents, unstable performance, etc., to improve heat resistance, Good chemical stability, the effect of solving the quality instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The present embodiment also provides the preparation method of above-mentioned metal release agent, comprises the following steps:

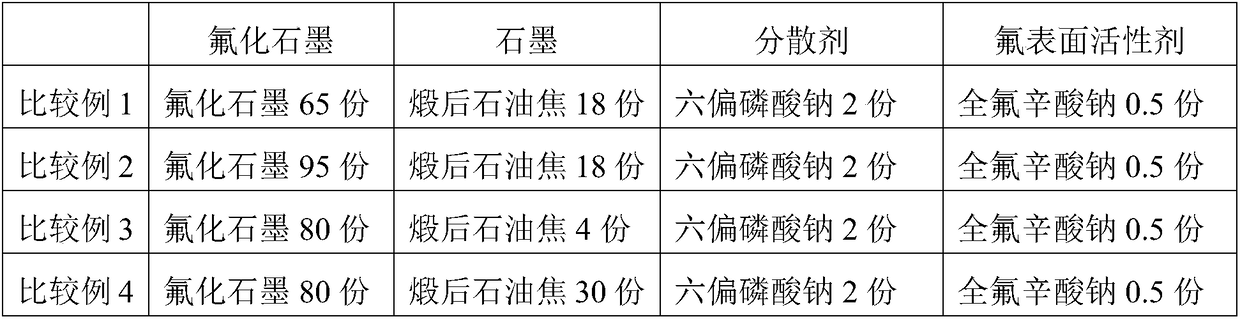

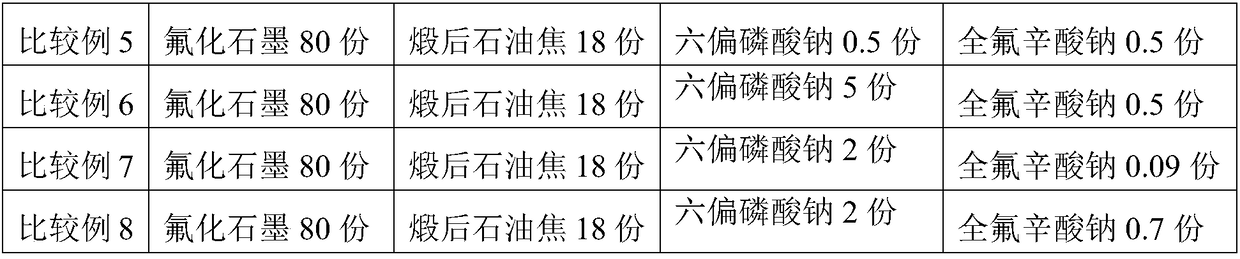

[0016] (1) Prepare materials according to the following parts by weight: 70 to 90 parts of graphite fluoride, 5 to 25 parts of graphite, 1 to 3 parts of dispersant, and 0.1 to 0.5 parts of fluorosurfactant;

[0017] (2) Preparation of release agent: add dispersant to fluorinated graphite, stir and mix uniformly, then add graphite and fluorosurfactant to the above mixture, and stir and mix uniformly to obtain metal release agent.

[0018] In use, after the metal powder is granulated, add 0.02 to 0.1 part by weight of the above metal release agent to 100 parts of the metal powder, stir and mix evenly, and then add it to a mold stamping machine for stamping. Preferably, 0.04-0.08 parts of metal release agent is added to 100 parts of metal powder.

Embodiment 1

[0021] The present embodiment provides a kind of metal release agent, and it is made up of the raw material of following parts by weight:

[0022] Graphite fluoride (F / C ratio 1.1, 10-20um): 80 parts

[0023] Graphite (5~10um): 18 parts of calcined petroleum coke

[0024] Dispersant: sodium hexametaphosphate 2 parts

[0025] Fluorosurfactant: Sodium perfluorooctanoate 0.5 parts

[0026] The preparation method of above-mentioned metal release agent, comprises the steps:

[0027] (1) Prepare materials according to the following parts by weight: 80 parts of fluorinated graphite, 17.5 parts of calcined petroleum coke, 2 parts of sodium hexametaphosphate, and 0.5 part of sodium perfluorooctanoate;

[0028] (2) Preparation of release agent: add sodium hexametaphosphate to fluorinated graphite, stir and mix evenly, then add calcined petroleum coke and sodium perfluorooctanoate to the above mixture, and stir and mix evenly to obtain metal release agent.

[0029] Application: After...

Embodiment 2

[0032] This embodiment provides a metal release agent, the preparation method of which is the same as in Example 1, consisting of the following raw materials in parts by weight:

[0033] Graphite fluoride (F / C ratio 1.1, 10-20um): 70 parts

[0034] Graphite (5~10um): 25 parts of flake graphite

[0035] Dispersant: 1.5 parts of sodium hexametaphosphate, 1.5 parts of sodium oleate

[0036] Fluorosurfactant: 0.1 part of sodium perfluorooctane sulfonate.

[0037] Application: After the iron powder is granulated, add 0.04 parts of metal release agent to every 100 parts of metal powder, directly mix the metal release agent with the granulated iron powder and stir evenly, then add it to the mold stamping machine for stamping.

[0038] After the casting is formed, the surface is smooth, and there are no stretch marks on the surface of the mold and the casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com