Method of manufacturing mounting board with reflector

A manufacturing method and technology of mirrors, which are applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of mirror deformation, defective products, inability to increase the effective utilization rate, etc., and achieve a narrower interval. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

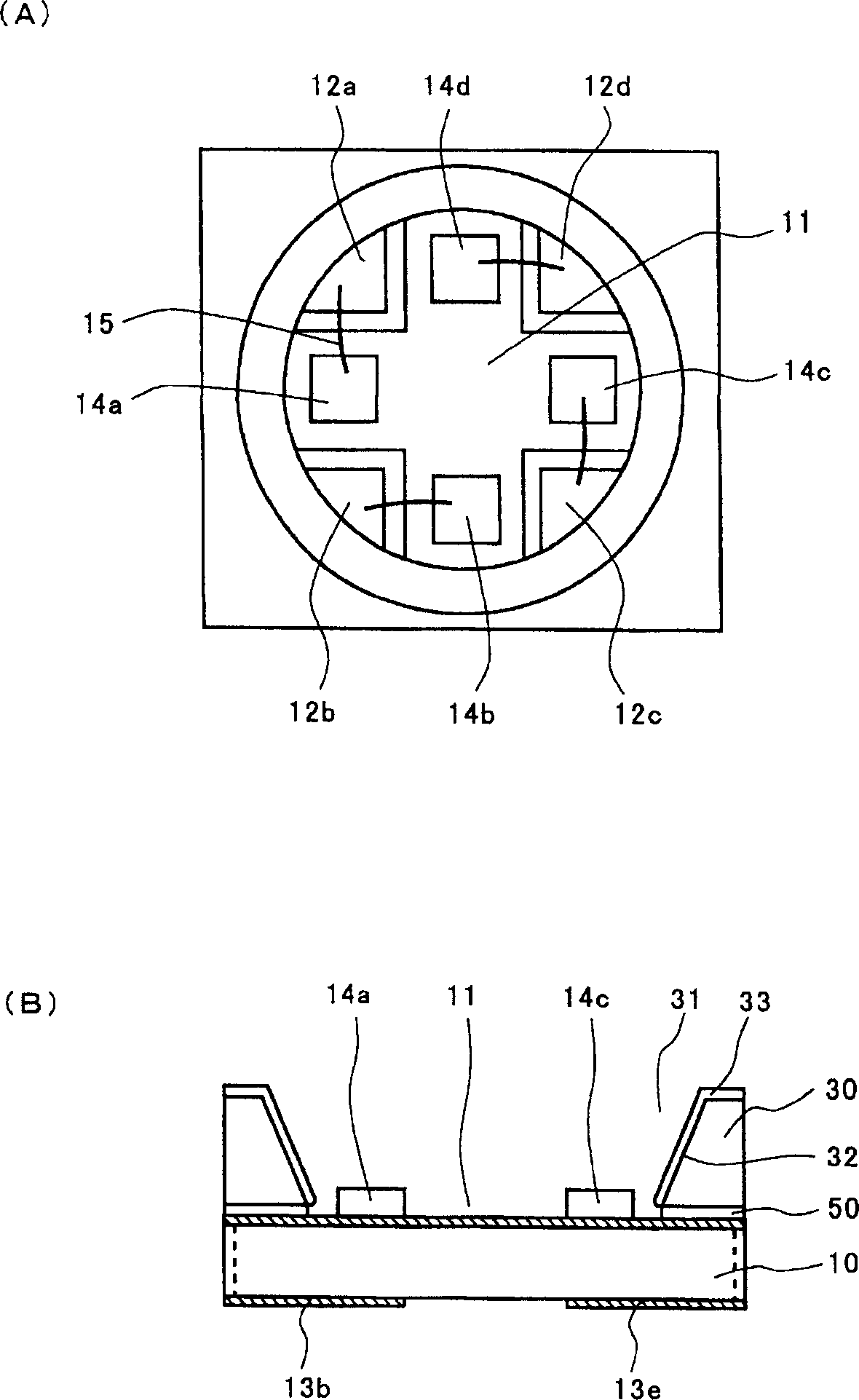

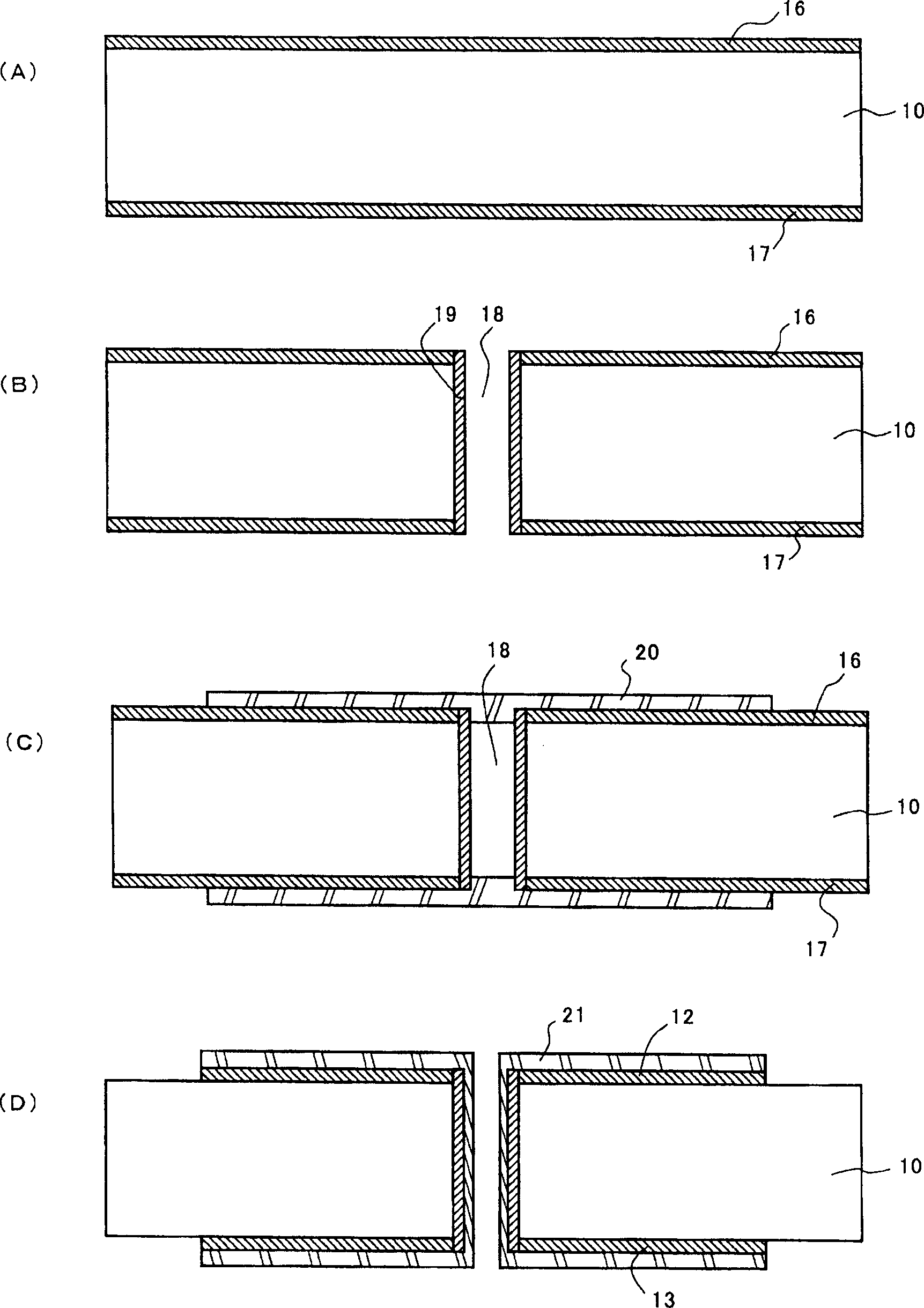

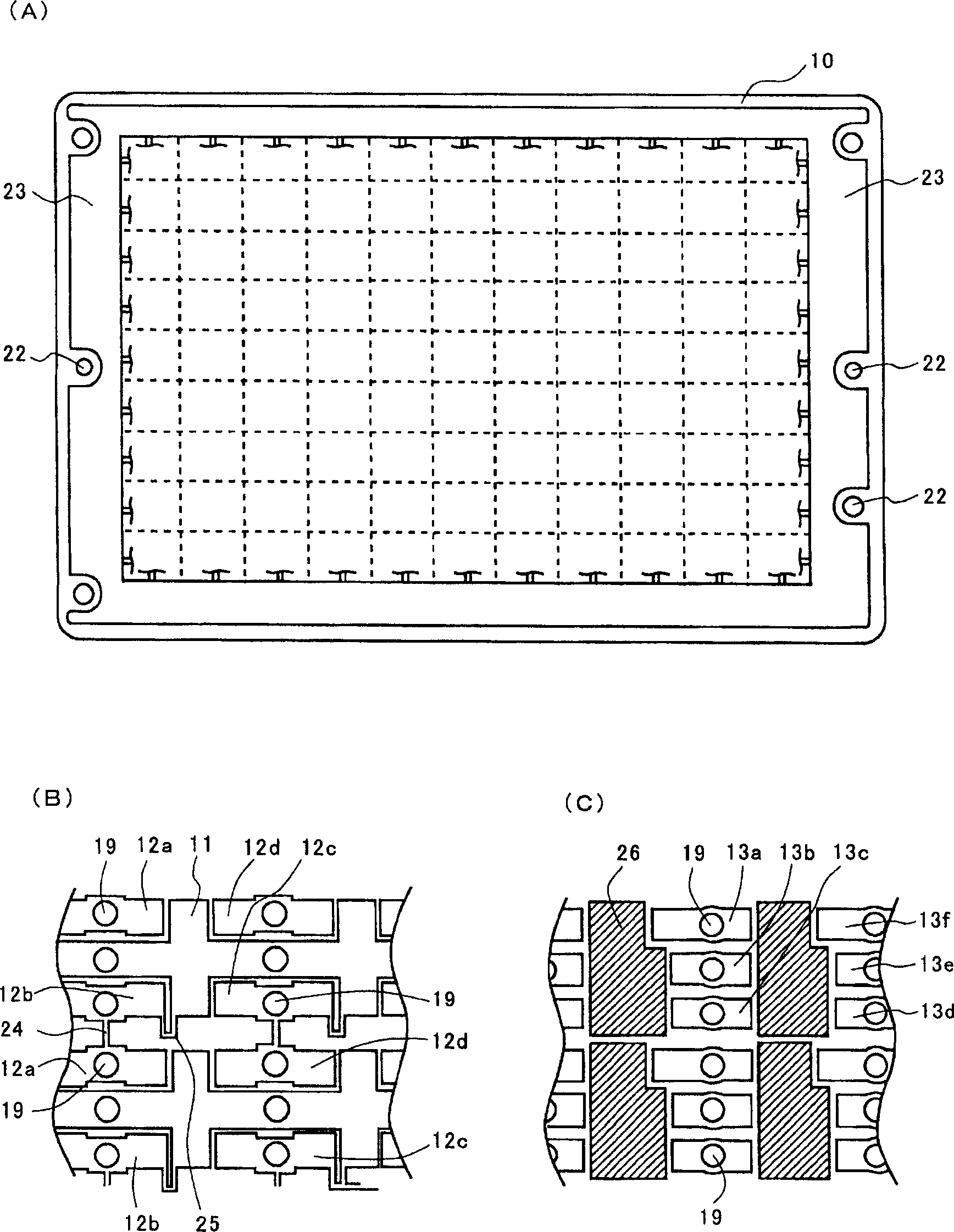

[0063] first, figure 1 A mirror mounted substrate completed by the manufacturing method of the present invention is shown. figure 1 (A) is the above picture, figure 1(B) is its cross-sectional view. Cross-shaped common electrodes 11 are provided on the mounting substrate, individual electrodes 12a, 12b, 12c, 12d are provided at the four corners, and lead-out electrodes 13a, 13b connected to corresponding electrodes through through-hole electrodes are provided below. On the upper side of the mounting substrate 10, the reflector 30 is pasted through the adhesive layer 50, so that a part of the common electrode 11 and the individual electrodes 12a, 12b, 12c, and 12d are exposed, and the inclined surface 32 and the upper surface of the through hole 31 of the reflector 30 are exposed. A reflective coating 33 is provided. Four light-emitting elements 14a, 14b, 14c, and 14d are respectively fixed on the cross protruding parts of the common electrode 11, and the common electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com