The second and fourth precast concrete parts and the joining method of the precast concrete parts

A technology of precast concrete and joining method, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of increased burden, complicated manufacture of PCa parts, and increased cost, and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

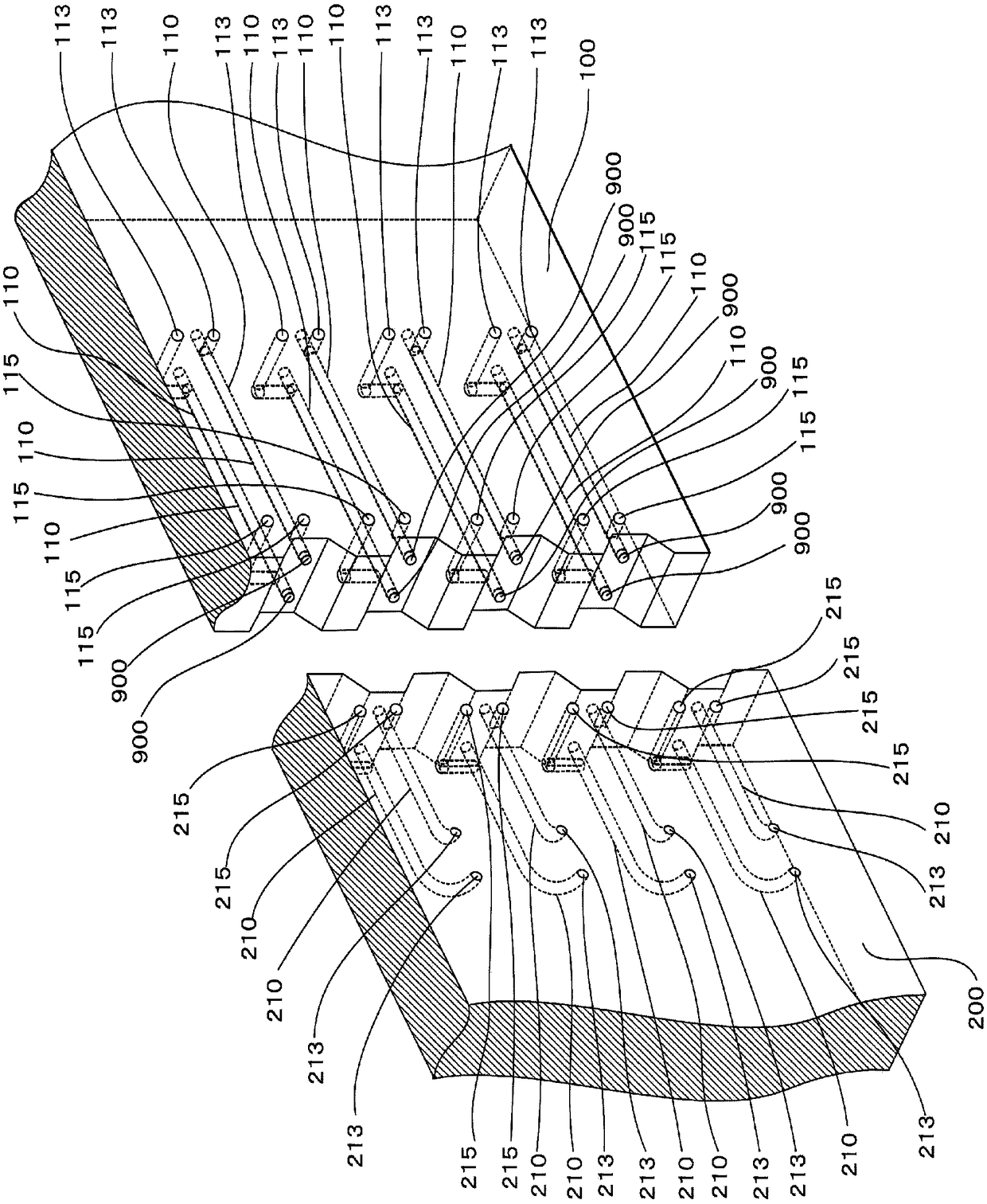

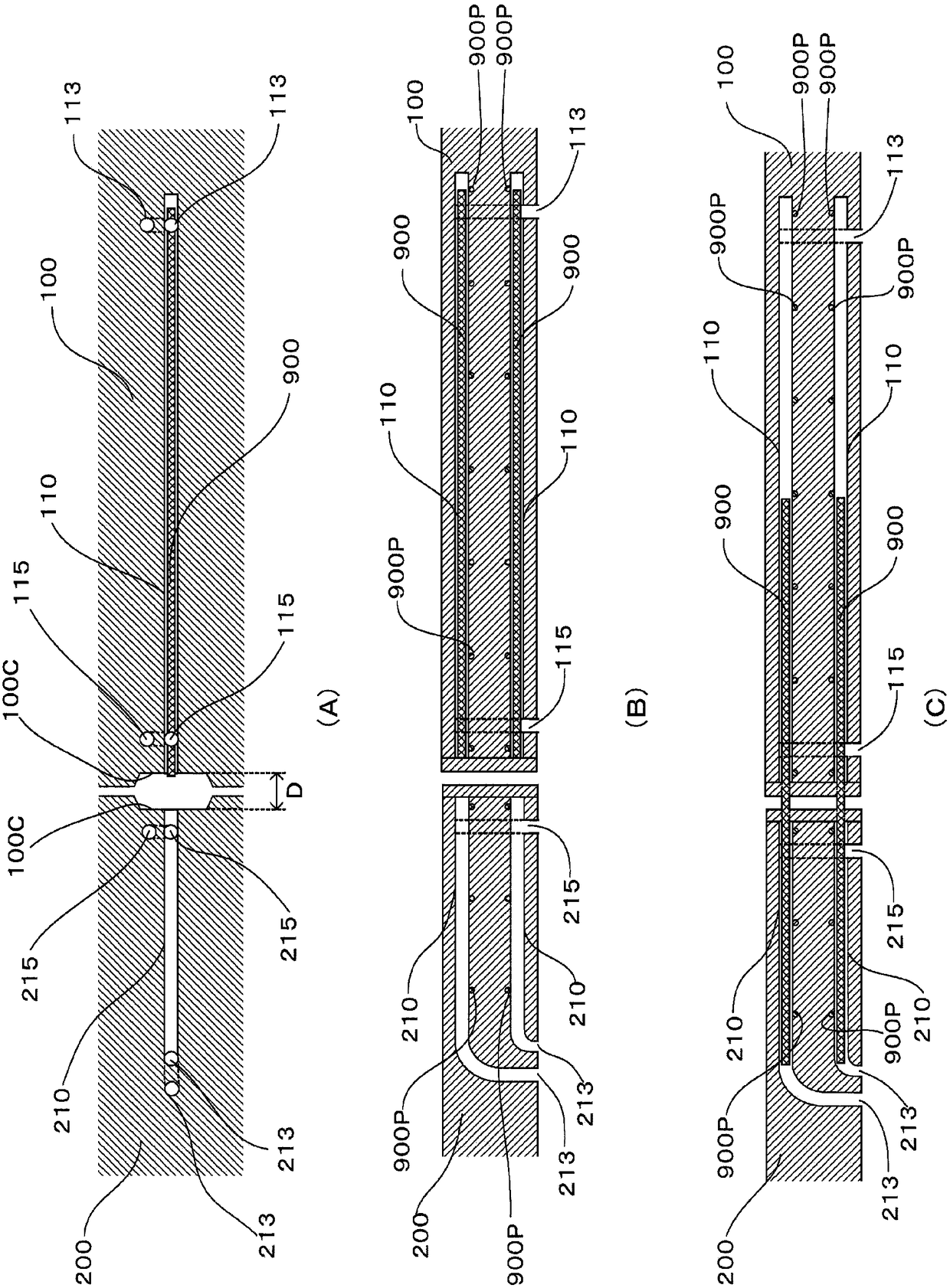

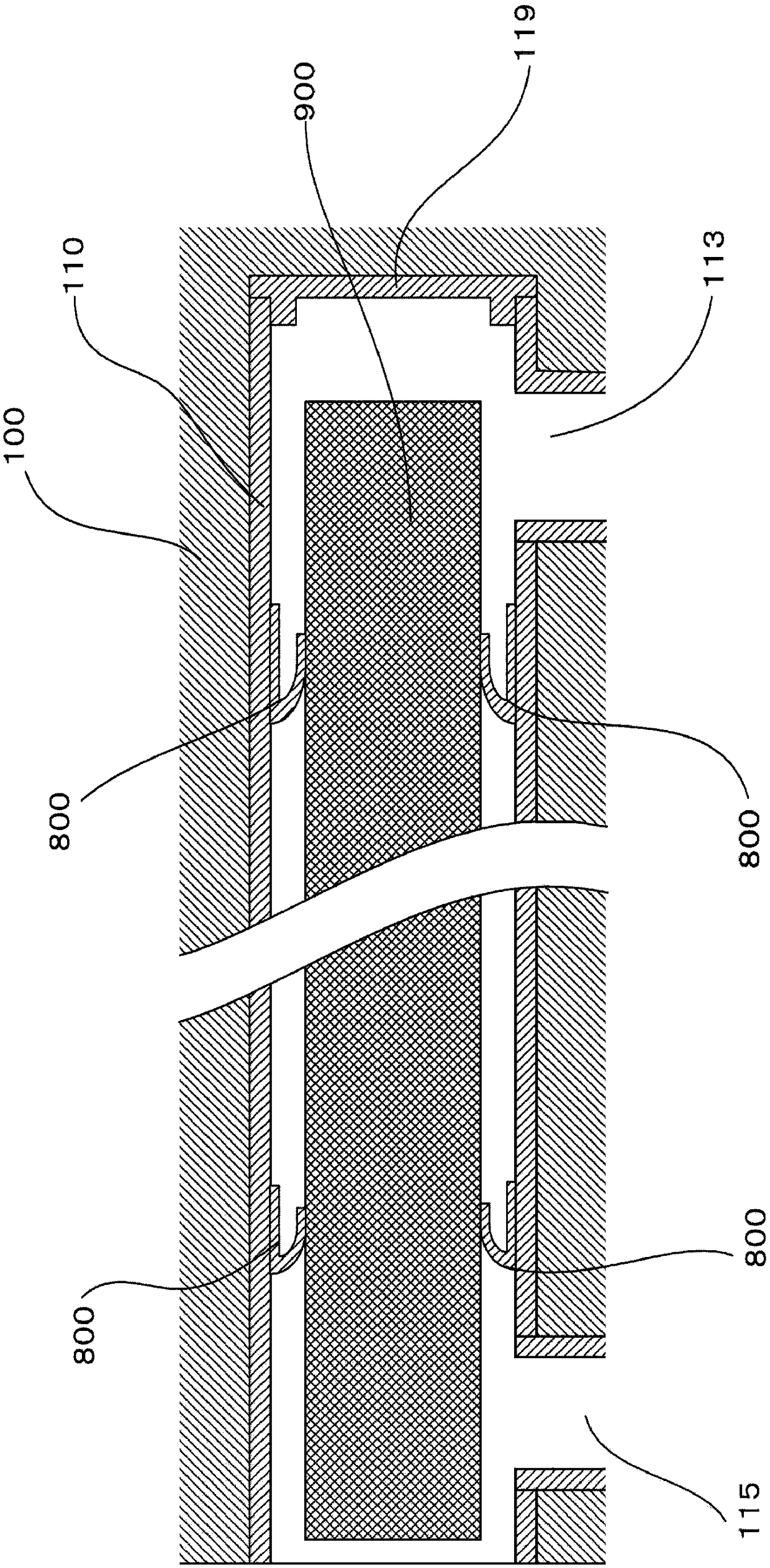

[0062] Hereinafter, a precast concrete part provided with a joining member and a precast concrete part joining method using the precast concrete part according to the present invention will be described with reference to the drawings. In addition, in the following description, the same reference numerals are used for the same constituent elements, even for constituent elements that can be adopted in other forms, and overlapping descriptions, structures, and expressions may be partially omitted. In addition, for convenience of description, the size, ratio, etc. of each component shown in the drawings may differ from actual ones.

[0063] In the present invention, as figure 1 and figure 2 As shown, for example, a first tubular member 110 is preliminarily installed in a first PCa member 100 such as an anti-seismic wall, and a steel bar 900 is movably packed into the inside of the tubular member 110, thereby, the first PCa member can be In 100, the first PCa member 100 with st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com