Vacuum pump, protection net, and contact component

A technology for contacting parts and vacuum pumps, which is applied in the direction of pump components, pumps, and parts of pumping devices for elastic fluids, etc. It can solve the problems of the decrease of the conductance of the vacuum pump 1 and the adverse effects of the exhaust performance of the vacuum pump 1, and achieve the goal of reducing the height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0077] (Embodiment 1: An embodiment in which the contact portion of the rotating body (shaft 7 or rotor 8) is formed into a shape with low resistance)

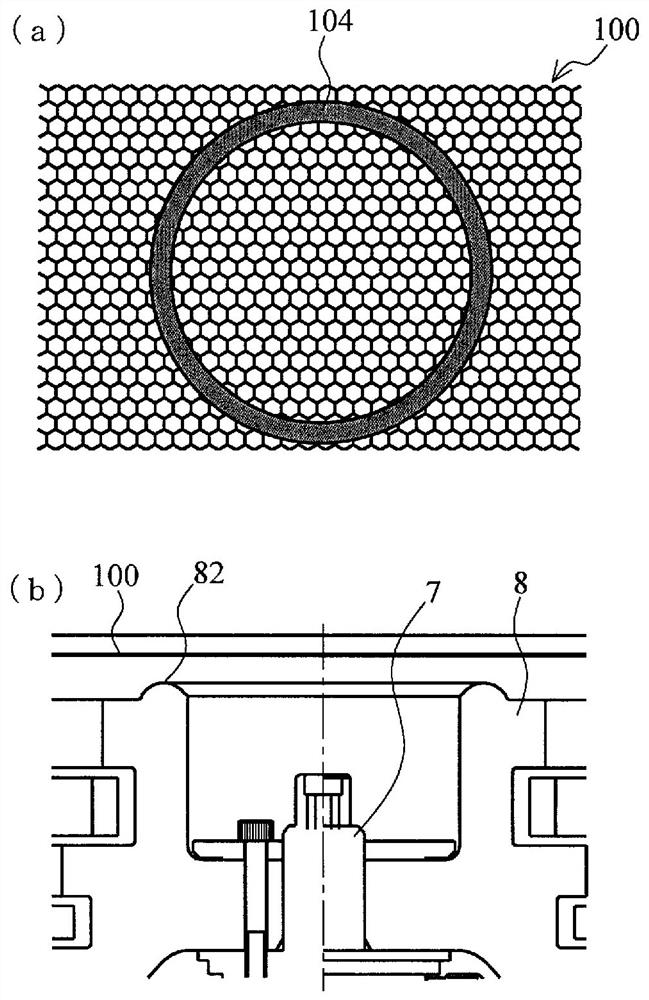

[0078] figure 2 It is a diagram for explaining an embodiment in which the contact portion of the shaft 7 with the protection net 100 is formed into a shape with low resistance.

[0079] exist figure 2 In the illustrated embodiment, the front end portion of the shaft 7 that contacts the shaft 7 when the protection net 100 is deformed is formed into a shape with low resistance, and the protection net 100 is supported to prevent entanglement.

[0080] exist figure 2 In (a), the front end portion 72 of the shaft 7 is spherical. exist figure 2 In (b), the front-end|tip part 74 of the shaft 7 is made into R chamfer shape.

[0081] image 3 It is a diagram for explaining an embodiment in which the contact portion of the rotor 8 with the protective net 100 is formed into a shape with low resistance.

[0082] exist image 3...

Embodiment approach 2

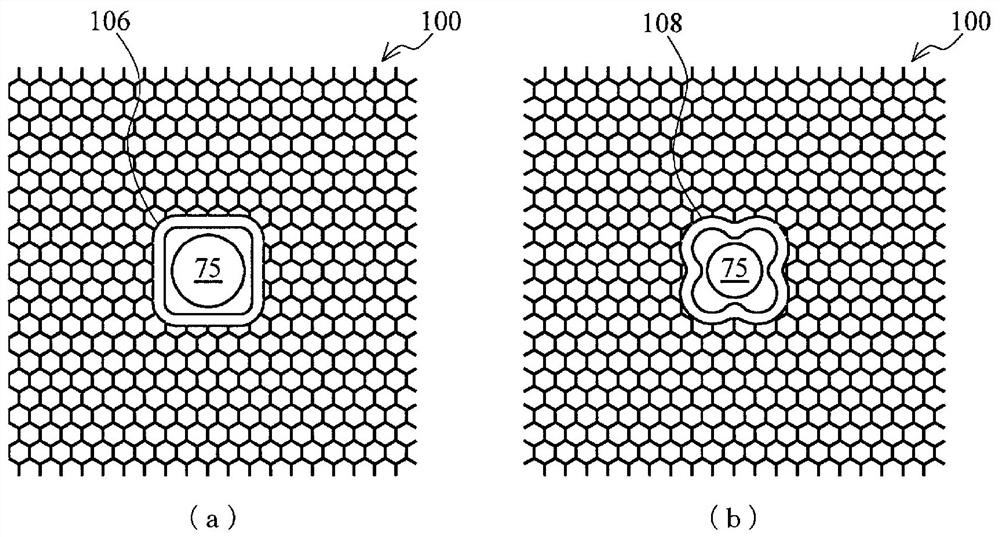

[0084] (Embodiment 2: An embodiment in which holes are opened in the protection net 100 and a shape is provided to contact and support a rotating body)

[0085] Figure 4 It is a diagram for explaining an embodiment in which holes are opened in the protection net 100 and a shape that is provided in contact with a rotating body and supported is provided.

[0086] In this embodiment, a hole is preliminarily drilled at the portion of the protection net 100 that contacts the protrusion 75 of the shaft 7 or the protrusion 85 of the rotor 8. If the protection net 100 deforms, the protrusion 75 of the shaft 7 or the rotor 8 The protrusions 85 immediately contact the holes of the protective net 100 to support the deformation of the protective net 100 .

[0087] Figure 4 (a) is a figure which shows the example which provided the tapered protrusion part 75 in the shaft 7, and made it contact the hole of the protection net 100, and supported it.

[0088] Figure 4 (b) is a diagram s...

Embodiment approach 3

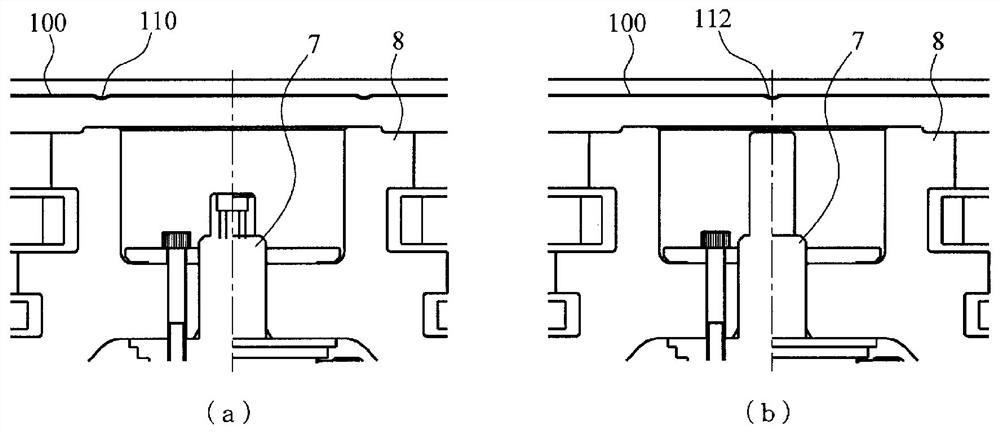

[0099](Embodiment 3: In Embodiments 1 and 2, the contact portion (contact portion and protrusion) of the rotating body is configured with other components)

[0100] Figure 7 It is a figure explaining the embodiment which comprised the contact part (contact part) of the rotating body of Embodiment 1 and the contact part (protrusion part) of Embodiment 2 with another member.

[0101] Figure 7 (a) means that the figure 2 (a) is a diagram showing an example in which the tip portion 72 (formed integrally) of the shaft 7 according to Embodiment 1 is constituted by another member 78 .

[0102] Figure 7 (b) means that the Figure 4 (a) is a diagram showing an example in which the protruding portion 75 (formed integrally) of the shaft 7 according to the second embodiment is constituted by another member 79 .

[0103] Figure 7 (c) means that the image 3 (a) is a diagram showing an example in which the contact portion 82 (formed integrally) of the rotor 8 according to Embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com