Novel wet-type electric dust removal device

A wet electrostatic precipitator, a new type of technology, applied in electrode cleaning, electrostatic separation, electrostatic effect separation, etc., to reduce volume, improve collection efficiency, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the drawings and specific embodiments, but the protection scope of the present invention is not limited to this.

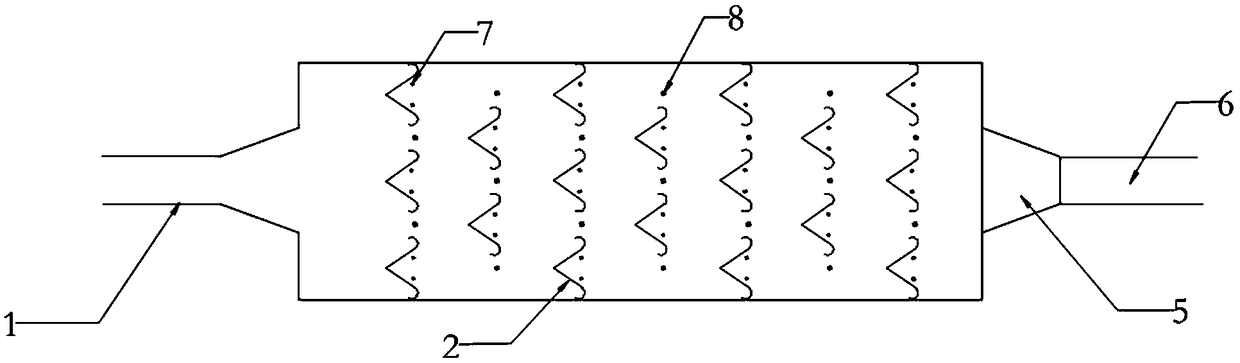

[0032] Such as figure 1 As shown, a new type of wet electric dust removal device according to the present invention includes a dust removal chamber 10 and a sewage chamber 4 integrated up and down. The dust removal chamber 10 and the sewage chamber 4 are connected. The dust removal chamber 10 has two opposite side walls. An air inlet 1 is provided on one side wall, and a defogging area 5 and an air outlet 6 are provided on the other side wall. The gas enters the dust removal chamber 10 through the air inlet 1 and then passes through the defogging area 5 and then is discharged from the air outlet 6;

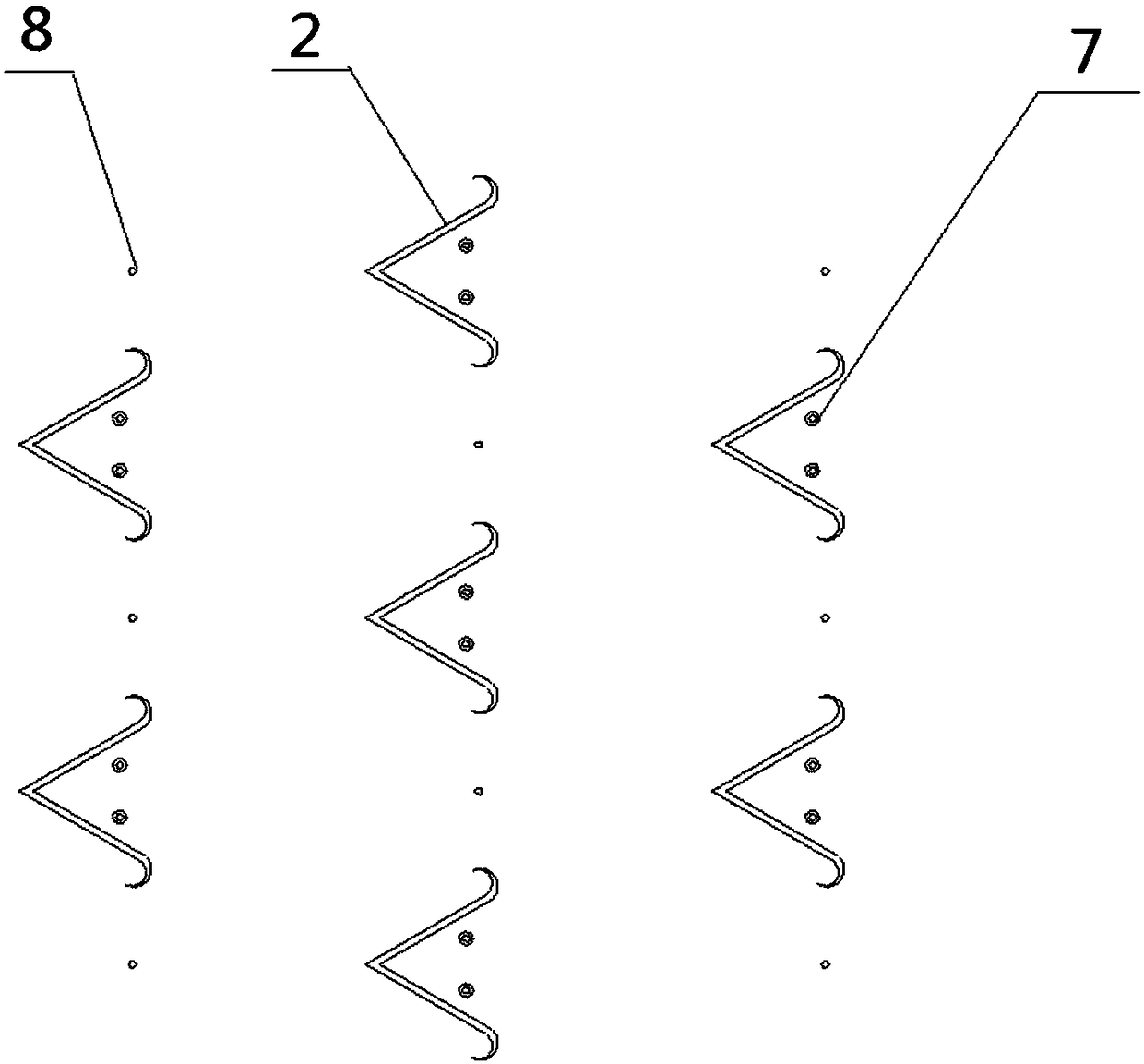

[0033] Such as figure 2 As shown, the dust collection chamber 10 is provided with a plurality of dust collecting plates 2, a plurality of corona wires 8 and a spray pipe 7, and the dust collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com