Field-effect sensor for detecting hydroxyl free radicals and preparation method of field-effect sensor

A free radical and field effect technology, applied in the field of sensing and detection, can solve the problems of expensive instruments, pollution, short life, etc., and achieve the effect of high selectivity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

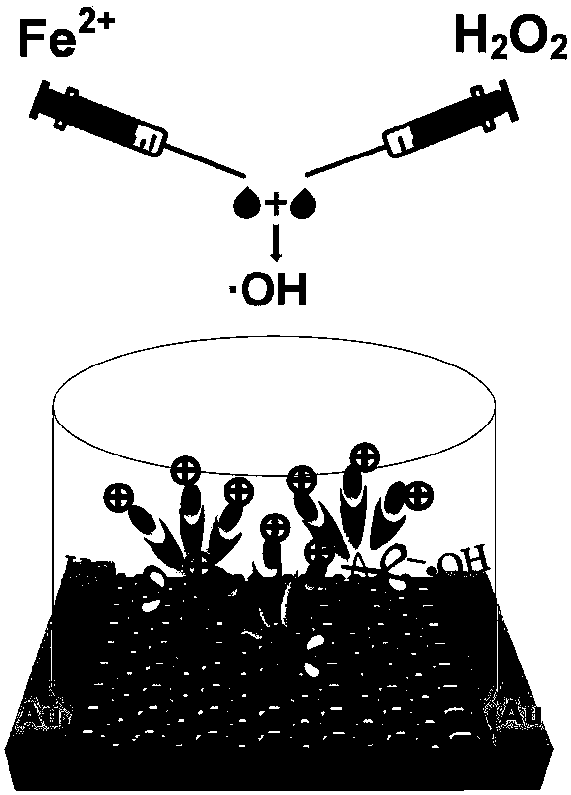

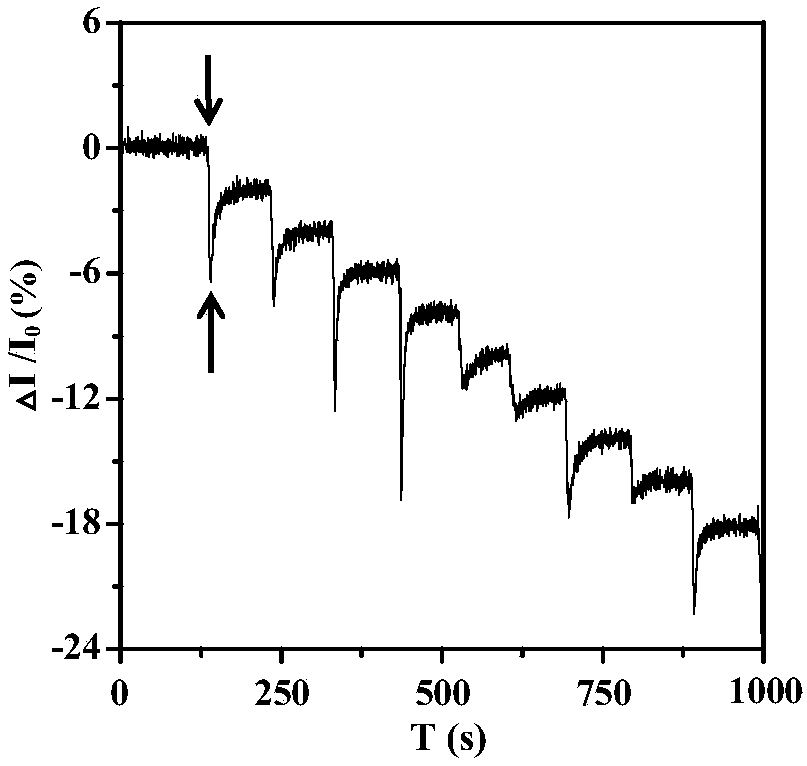

Method used

Image

Examples

Embodiment 1

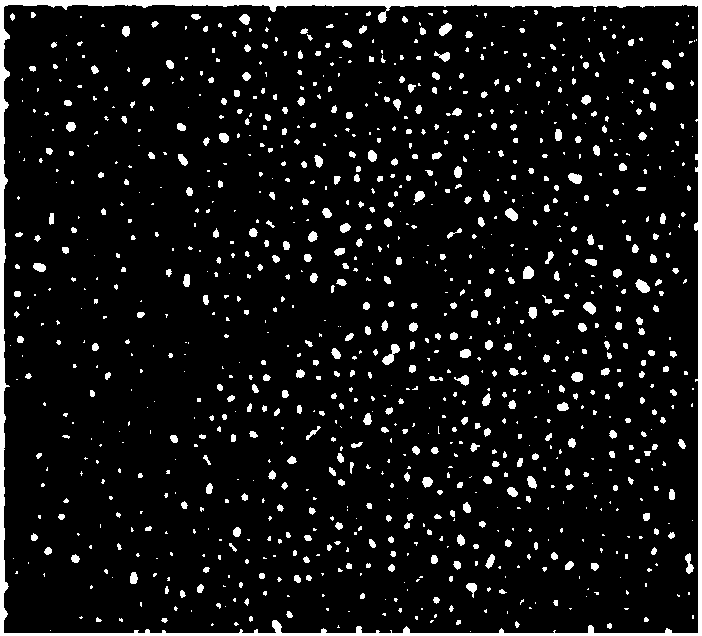

[0025] First, a single-layer graphene film was prepared on a 25-μm-thick copper foil by chemical vapor deposition, and the graphene was transferred to clean SiO 2 / Si substrate. Cr / Au (5 / 50 nm) source-drain electrodes were prepared by thermal evaporation, and then annealed in an Ar atmosphere at 300°C in a tube furnace for 30 minutes. Secondly, a layer of 8.0 nm gold film was evaporated on the surface of the graphene film by thermal evaporation technology, and uniformly distributed gold nanoparticles were obtained by annealing at 230 °C for 0.5 hours in a tube furnace ( figure 1 ). Then, 10 mM cysteamine was immobilized to the surface of gold nanoparticles via Au-S bonds. Finally, under the catalysis of EDC and NHS, 10 μM protoporphyrin was covalently immobilized to the electrode surface by forming amide bonds at a reaction temperature of 25 °C and a reaction time of 15 hours. Rinse with twice distilled water, and then in high-purity N 2 Blow dry, and the field effect tran...

Embodiment 2

[0027] First, a single-layer graphene film was prepared on a 25-μm-thick copper foil by chemical vapor deposition, and the graphene was transferred to clean SiO 2 / Si substrate. Cr / Au (5 / 50 nm) source-drain electrodes were prepared by thermal evaporation, and then annealed in an Ar atmosphere at 300 °C in a tube furnace for 30 minutes. Secondly, a 4.0 nm gold film was evaporated on the surface of the graphene film by thermal evaporation technology, and uniformly distributed gold nanoparticles were obtained by annealing at 200 °C for 0.5 hours in a tube furnace. Then, 10 mM cysteamine was immobilized to the gold nanoparticle surface via Au-S bonds. Finally, under the catalysis of EDC and NHS, 10 μM protoporphyrin was covalently immobilized on the electrode surface by forming amide bonds at a reaction temperature of 20 °C and a reaction time of 10 hours. Rinse with twice distilled water, and then in high-purity N 2 Blow dry, and the preparation of the field effect transistor ...

Embodiment 3

[0029] First, a single-layer graphene film was prepared on a 25-μm-thick copper foil by chemical vapor deposition, and the graphene was transferred to clean SiO 2 / Si substrate. Cr / Au (5 / 50 nm) source-drain electrodes were prepared by thermal evaporation, and then annealed in an Ar atmosphere at 300 °C in a tube furnace for 30 minutes. Secondly, a 2.0 nm gold film was evaporated on the surface of the graphene film by thermal evaporation technology, and uniformly distributed gold nanoparticles were obtained by annealing at 170 °C for 0.5 hours in a tube furnace. Then, 10 mM cysteamine was immobilized to the gold nanoparticle surface via Au-S bonds. Finally, under the catalysis of EDC and NHS, 10 μM protoporphyrin was covalently immobilized on the electrode surface by forming amide bonds at a reaction temperature of 25 °C and a reaction time of 5 hours. Rinse with twice distilled water, and then in high-purity N 2 Blow dry, that is, complete the preparation of the field effec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com