A stainless steel-based composite hydrogen permeation resistance material and its preparation method

A permeable material, stainless steel technology, applied in the field of stainless steel-based composite hydrogen-resistant permeable material and its preparation, can solve the problem of poor high-temperature bonding force between alumina coating and stainless steel substrate, affecting the coating's hydrogen resistance and permeation performance, and the large gap in thermal expansion coefficient and other problems, to achieve the effect of improving hydrogen permeation resistance, excellent deposition uniformity, and good thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

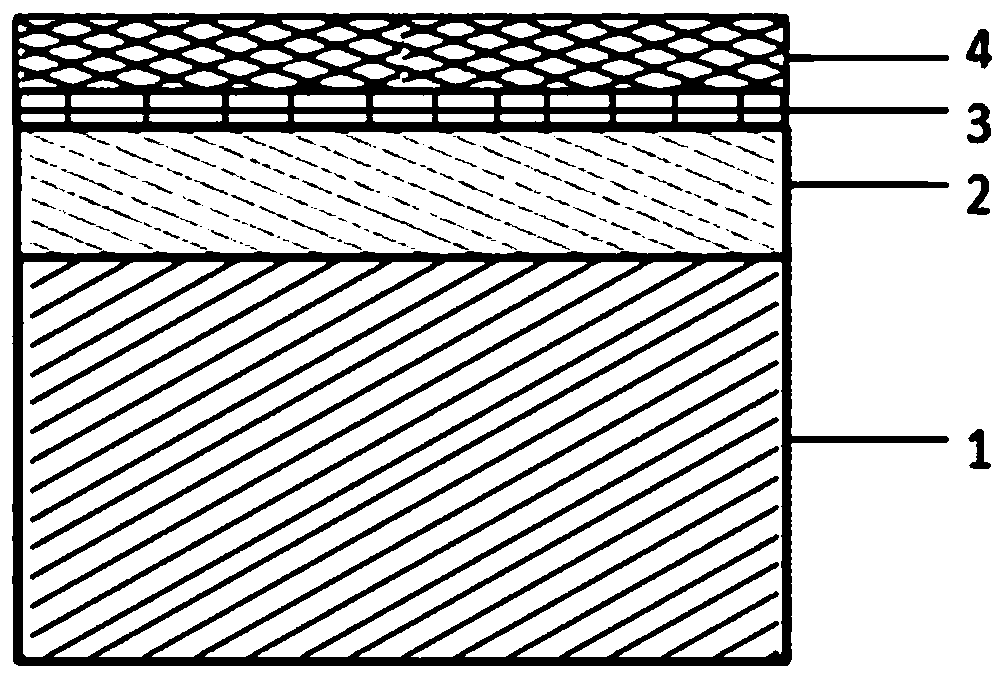

[0023] The preparation method of the stainless steel-based composite hydrogen permeation resistance material proposed by the present invention comprises the following steps:

[0024] (1) The stainless steel sheet is polished with sandpaper, then polished with a polishing paste, and finally the stainless steel sheet is ultrasonically cleaned and dried, and the unpolished surface of the stainless steel sheet is sealed with adhesive tape;

[0025] The specific process can be as follows: the 316L stainless steel sheet is polished with 800#, 1000#, 1500#, 2000#, 3000#, 5000#, 7000# silicon carbide sandpaper in sequence, and then the diamond polishing paste with a particle size of 0.5 μm is used Carry out polishing, and finally the sample is ultrasonically cleaned, and the solvents are ethanol, acetone, and deionized water in sequence, and the time for each cleaning is 5 minutes. After the sample is cleaned, use a hair dryer to dry the sample, and seal the unpolished side with adhes...

Embodiment 1

[0034] (1) Polish the stainless steel sheet with sandpaper, then polish it with polishing paste, and finally clean the sample ultrasonically, dry it, and seal the unpolished side with adhesive tape;

[0035] (2) the stainless steel sheet of above-mentioned step (1) is placed in activation solution and carries out activation treatment, and described activation solution is the hydrochloric acid that molar concentration is 0.12mol / L and molar concentration is 1.84mol / L sulfuric acid, by volume ratio 1 : 10 phases are mixed, the activation treatment temperature is 40°C, and the activation treatment time is 30 seconds;

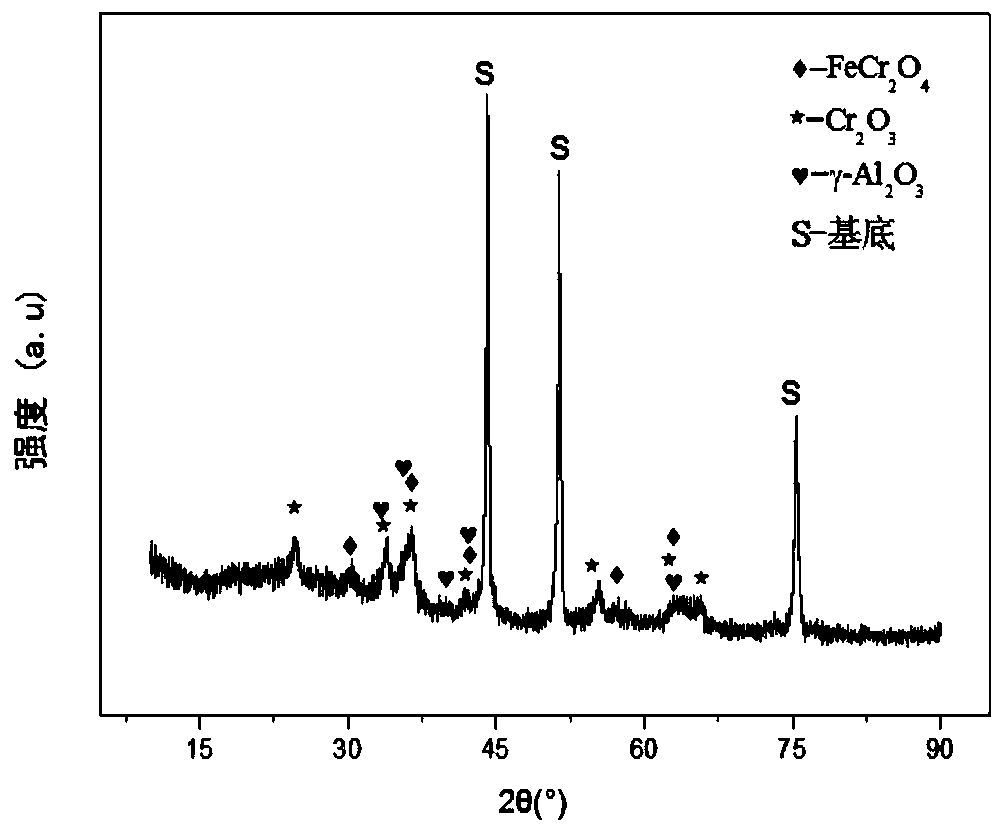

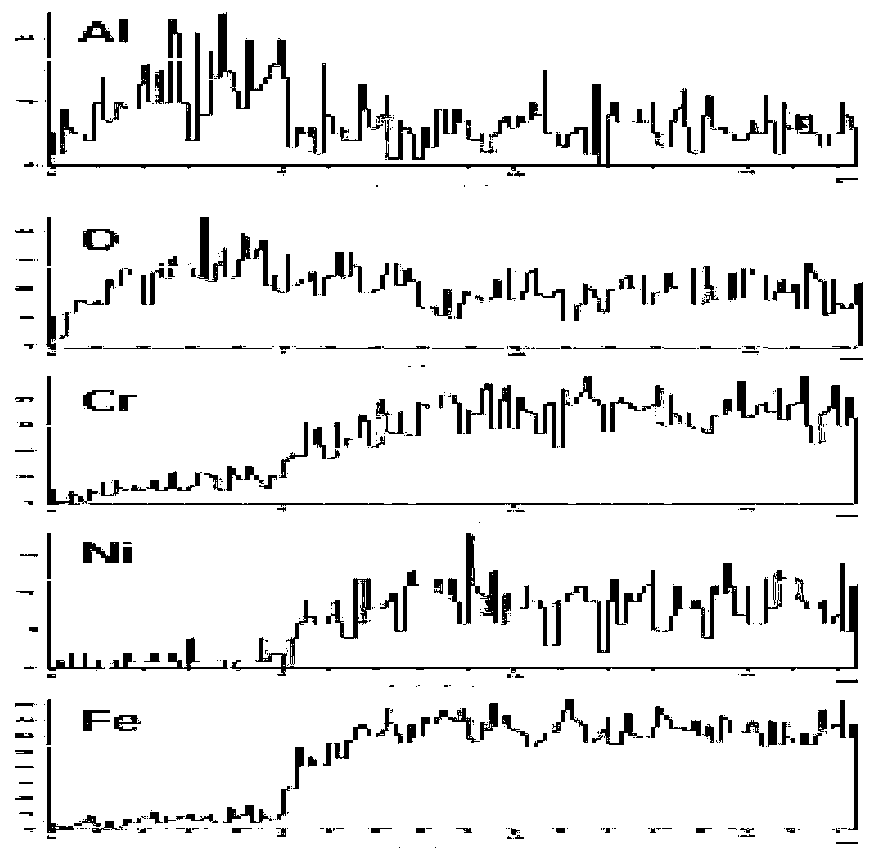

[0036] (3) the stainless steel sheet of above-mentioned step (2) is placed in coloring liquid to carry out coloring treatment through the activation treatment, and the composition of described coloring liquid is: concentrated sulfuric acid (H 2 SO 4 ): 280mL / L, chromic anhydride (CrO 3 ): 250g / L, the coloring treatment temperature is 80°C, the coloring treatment ...

Embodiment 2

[0044] (1) Polish the stainless steel sheet with sandpaper, then polish it with polishing paste, and finally clean the sample ultrasonically, dry it, and seal the unpolished side with adhesive tape;

[0045] (2) the stainless steel sheet of above-mentioned step (1) is placed in activation solution and carries out activation treatment, and described activation solution is the hydrochloric acid that molar concentration is 0.12mol / L and molar concentration is 1.84mol / L sulfuric acid, by volume ratio 1 : 10 phases are mixed, the activation treatment temperature is 40°C, and the activation treatment time is 30 seconds;

[0046] (3) the stainless steel sheet of above-mentioned step (2) is placed in coloring liquid to carry out coloring treatment through the activation treatment, and the composition of described coloring liquid is: concentrated sulfuric acid (H 2 SO 4 ): 280mL / L, chromic anhydride (CrO 3 ): 250g / L, the coloring treatment temperature is 80°C, the coloring treatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com