A kind of preparation method of ester type highly dispersed high slump retention polycarboxylate water reducer

A high-dispersion, polycarboxylic acid technology, applied in the field of building admixtures, can solve the problems of slump, concrete slump loss, concrete slump loss and other problems that cannot be fundamentally solved, and achieves good initial dispersion performance, Ease of construction and pumping, improved dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

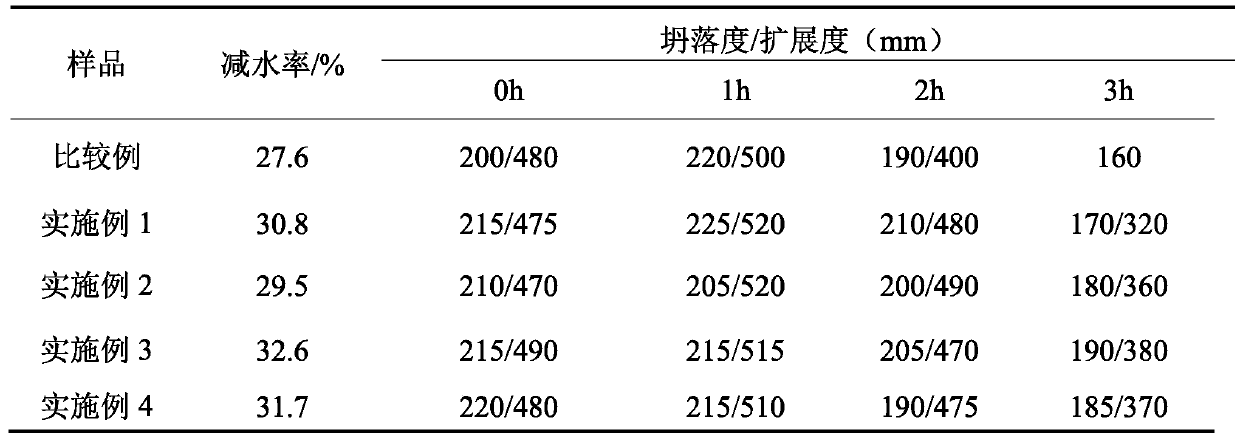

Examples

Embodiment 1

[0025] (1) Esterification reaction: add 70.80g of maleic anhydride, 110.00g of polyether diol with a molecular weight of 400, and 2.10g of hydroquinone into the first reaction vessel for mixing, and heat up to 60-80°C under nitrogen protection. ℃, then add 3.66g p-toluenesulfonic acid, raise the temperature to 100℃, keep the temperature for 2 hours, remove water during the reaction, cool down to room temperature after the reaction, and obtain the first mixture containing esterification product and unreacted unsaturated acid anhydride.

[0026] (2) Copolymerization: In the second reaction vessel, add 12.00g of the first mixture prepared in step (1), 80.00g of methoxypolyethylene glycol propylene glycol acrylate with a molecular weight of 1200 and 20.00g of isoamylene with a molecular weight of 3000 Alcohol polyethylene glycol ether, and 118.00g of water, stirred until uniformly dissolved to obtain a comonomer mixture solution, then added 0.80g of hydrogen peroxide, and mixed asc...

Embodiment 2

[0029] (1) Esterification reaction: Add 42.2g of itaconic anhydride, 160.00g of polyether diol with a molecular weight of 800, and 2.66g of phenothiazine into the first reaction vessel for mixing, and heat up to 60-80°C under nitrogen protection , and then added 4.25g of benzenesulfonic acid, raised the temperature to 120°C, kept the temperature for 2h, removed water during the reaction, and cooled down to room temperature after the reaction, to obtain the first mixture containing the esterification product and unreacted unsaturated anhydride.

[0030] (2) Copolymerization: In the second reaction vessel, add 10.00g of the first mixture, 90.00g of methoxypolyethylene glycol methacrylate with a molecular weight of 3000 and 10.00g of isopentyl with a molecular weight of 2400 in the second reaction vessel Enol polyethylene glycol ether, and 127.00g of water, stirred until dissolved evenly, to obtain a comonomer mixture solution, and ammonium persulfate aqueous solution (wherein, am...

Embodiment 3

[0033] (1) Esterification reaction: Add 51.68g of succinic anhydride, 210.00g of polyether diol with a molecular weight of 1000, and 3.60g of diphenylamine into the first reaction vessel and mix them. Add 3.30 g of 98% concentrated sulfuric acid, raise the temperature to 110° C., keep the temperature for 2 hours, remove water during the reaction, and cool down to room temperature after the reaction to obtain the first mixture containing the esterification product and unreacted unsaturated anhydride.

[0034](2) Copolymerization: In the second reaction vessel, add 15.00g of the first mixture prepared in step (1), 85.00g of methoxypolyethylene glycol acrylate with a molecular weight of 3000 and 15.00g of isopentenol with a molecular weight of 1200 Polyethylene glycol ether, and 120.00g water, stir until dissolving evenly, obtain the comonomer mixture solution, and the aqueous solution of trichosanthes (wherein, trichosanthes 0.35g, water 30.00g), mercaptopropionic acid aqueous so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com