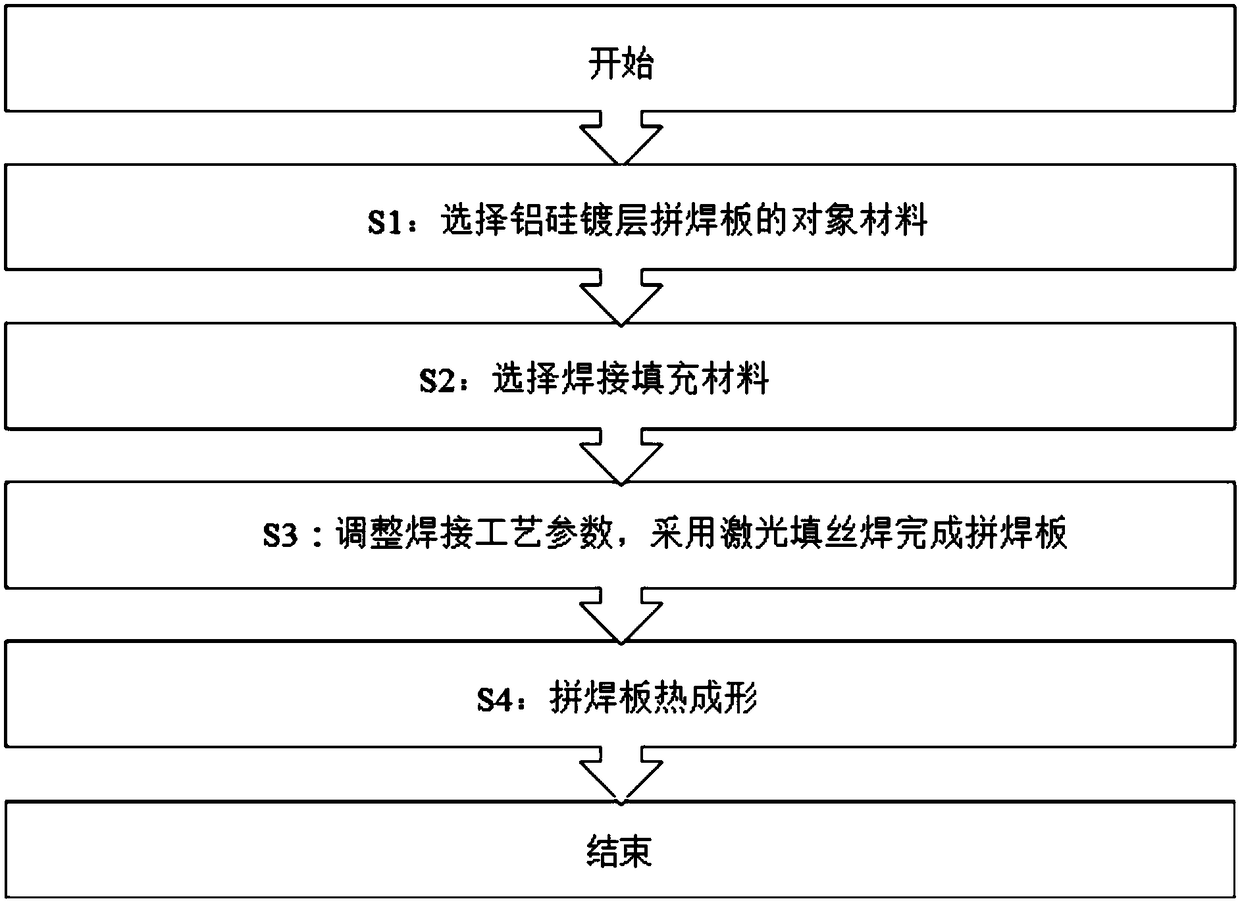

Method for manufacturing aluminum-silicon clad layer hot forming steel tailor-welded blank through laser filler wire welding process

A hot forming steel and laser wire filling technology, which is applied in laser welding equipment, manufacturing tools, welding/welding/cutting items, etc., can solve the problems of poor removal effect, expensive equipment, low work efficiency, etc., and achieve the reduction of straight line The requirements of high degree, the effect of improving production efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

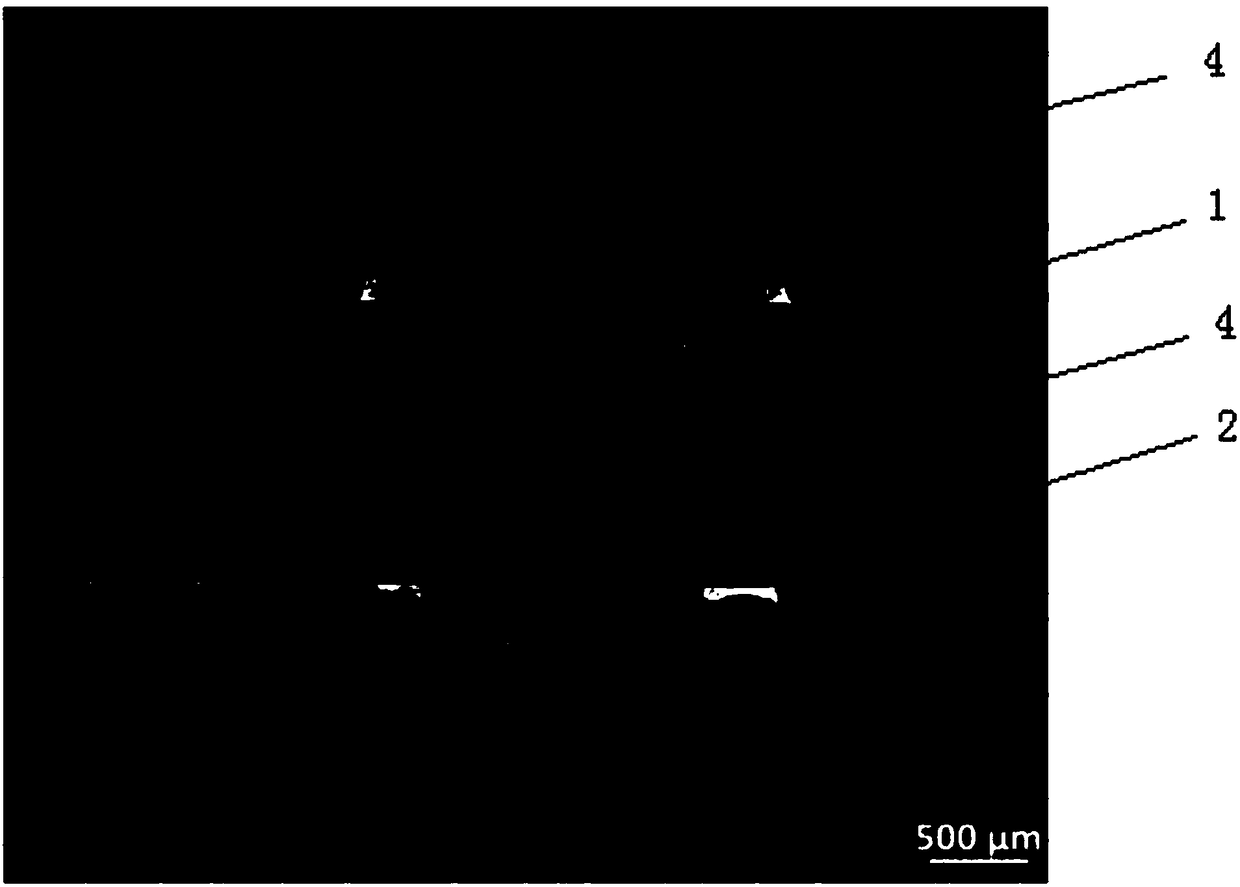

[0056] 22MnB5 hot-formed steel with aluminum-silicon coating 4 with a sheet thickness of 1.5mm is selected as the target material of the tailor-welded blank. The tailor-welded blank material is coated on both sides, and is divided into the first layer and the second layer from the outer layer to the inner layer And the third layer: the first layer is an Al-Si eutectic alloy layer with a thickness of 20 μm; the second layer under the first layer is an Fe-Al intermetallic compound layer with a thickness of 6-8 μm; the innermost layer The third layer is 22MnB5 steel base material 2 with a thickness of 1.45mm;

[0057] Prepare the weld joint, including adjusting the butt gap to 1.0mm, so that the straightness and shape of the shear section meet the welding requirements, and keep the weld joint clean.

[0058] Choose the welding method of laser wire-filling welding, choose nickel-based alloy welding wire with a diameter of 1.2mm, and adjust the laser power to 3kW, the welding speed...

Embodiment 2

[0061] As a comparative embodiment, the completely same sheet metal and weld joints with the same pretreatment method are selected as the target material of tailor-welded blanks.

[0062] The common laser self-fluxing welding method is selected, the laser power is also 3kW, the welding speed is increased to 5.8m / min, and Ar gas is selected as the shielding gas to complete the laser self-fluxing welding, and the second welding joint 3 can be obtained.

[0063] After undergoing exactly the same thermoforming process, the obtained welded joint structure is as follows Figure 4 As shown, the joint strength is only 1250MPa, and the fracture appearance of the joint is as follows Figure 5 .

[0064] Comparing the above two implementations, it can be seen that: when the same object material is selected (thickness and material are the same, and the form and thickness of the surface aluminum-silicon coating 4 are also exactly the same), the laser welding with filler wire and the ordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com