Metallurgical nozzle for protection pouring and method for protection pouring

A technology for protecting pouring and nozzles, applied in metal processing equipment, manufacturing tools, casting melt containers, etc. The effect of cloth science, shock reduction and liquid level calming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 protects the metallurgical nozzle for pouring

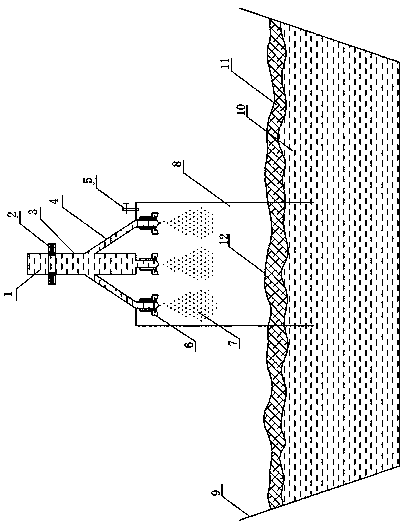

[0026] see figure 1 , the metallurgical nozzle is composed of a rainwater nozzle and a rainification chamber. The rainwater nozzle is composed of a sliding nozzle 2, a main nozzle 3, a branch nozzle 4, and an air nozzle 6. A sliding nozzle 2 is arranged above the main nozzle 3. The sliding nozzle 2 can be Slide up and down on the main nozzle 3 to control the flow of molten steel. 4 or 9 branch nozzles 4 are arranged below the main nozzle 3, a plurality of branch nozzles 4 are integrated with the main nozzle 3, and the lower ends of the main nozzle 3 and the branch nozzles 4 are respectively connected to the air nozzles 6. The rainwater outlet is located above the rainification chamber 8, and the air nozzle 6 is located above the rainification chamber 8. The rainification chamber 8 is a sealed refractory container filled with high-temperature argon gas and equipped with a pressure regulating valve. The lower ...

Embodiment 2

[0028] Embodiment 2 The method of using the above-mentioned metallurgical nozzle protection pouring

[0029] The molten steel 1 in the ladle passes through the main nozzle 3 and flows into each branch nozzle 4. In the rain chamber 8 with the function of protecting pouring, the gas nozzle 6 sprays high-temperature argon gas to rain the steel flow out of each branch nozzle 4 into droplets. , the steel droplets fall and pass through the 12 layers of refining slag in the lower part of the rain chamber 8, the inclusions and gases in the droplets are removed, and the clean steel droplets enter the static flow tundish 9.

Embodiment 3

[0030] Example 3 field application experiment

[0031] 1. In a billet continuous casting pouring example in a certain iron and steel plant, the rainification nozzle and the rainification chamber of the present invention used, the inner diameter of the main nozzle of the rainification nozzle is 80mm, the inner diameter of the branch nozzle is 40mm, and the number of branch nozzles is 4 , the arrangement of branch nozzles is uniform scattering in the center; the rain chamber is a sealed refractory container filled with high-temperature argon gas and equipped with a pressure regulating valve.

[0032] The method of protective pouring of molten steel is that the molten steel in the ladle passes through the main nozzle and flows into four branch nozzles. In the rain chamber with the function of protective pouring, the air nozzle sprays high-temperature argon gas to rain the steel flow out of the branch nozzles into droplets. , the average diameter of the droplet is 8mm, the steel d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com