Method for recycling tailings of magnetic separation by adopting preselection-calcination-magnetic levitation processes

A technology for magnetic separation of tailings and tailings, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of high cost, difficult industrial application, low recovery rate of magnetic iron, etc. Easy to achieve and save grinding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

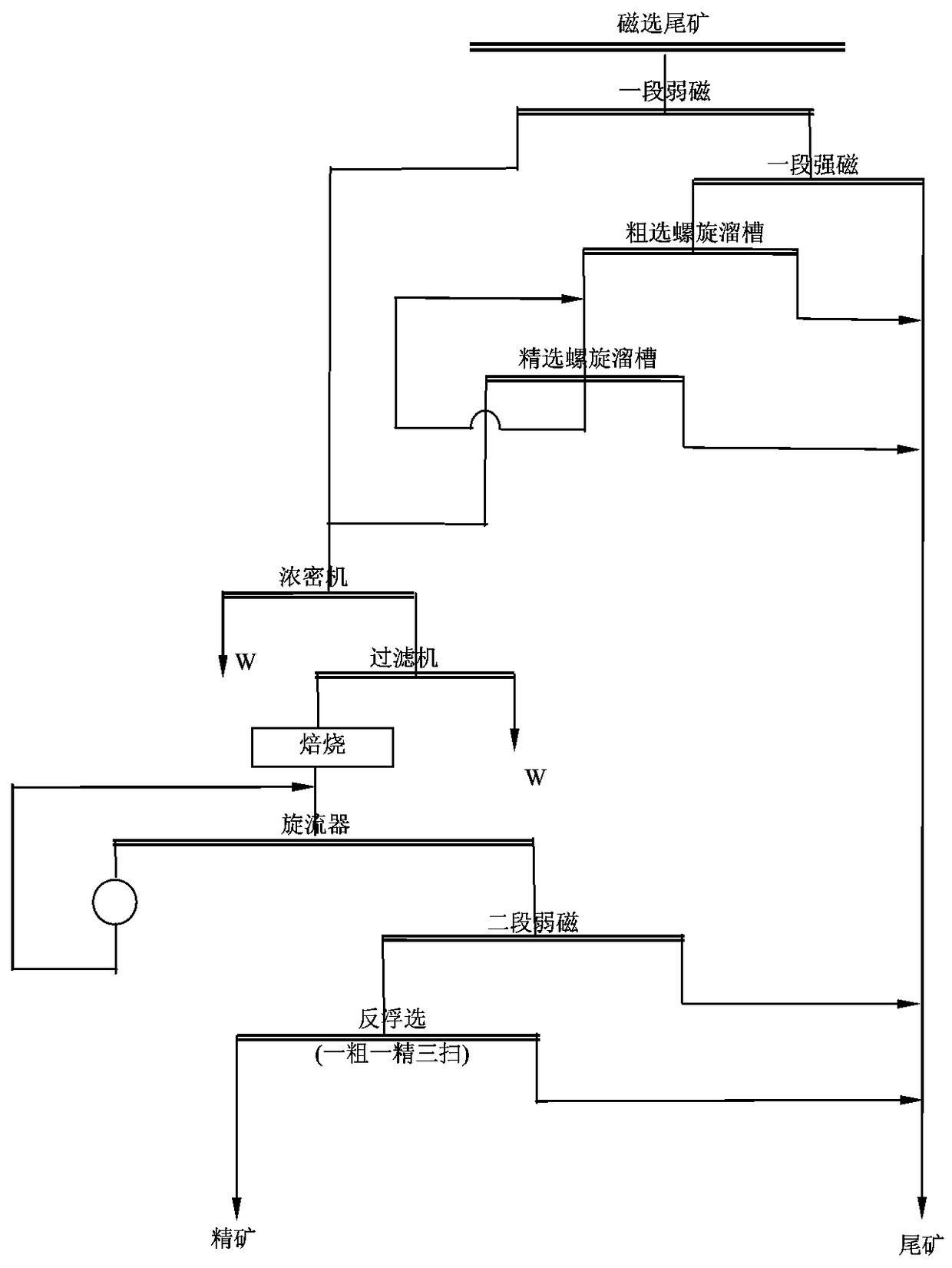

[0032] A method for reclaiming magnetic separation tailings by preselection-roasting-maglev process of the present invention comprises the following steps:

[0033] 1) Feed the magnetic separation tailings with an iron grade of 10.46% and a carbonate iron content of 3.5% into a section of weak magnetic to obtain a section of weak magnetic concentrate and a section of weak magnetic tailings with a grade of 27.35%; The tailings are fed into a section of strong magnetic to obtain a section of strong magnetic concentrate with a grade of 12.65% and a section of strong magnetic tailings with a grade of 5.92%;

[0034] 2) A section of strong magnetic concentrate is fed into the roughing spiral chute, and the coarse spiral concentrate is fed into the selected spiral chute to obtain the selected spiral chute concentrate, the selected spiral chute medium ore and the selected spiral chute tailings. The middle ore in the spiral chute returns to the selection spiral chute, the tailings of ...

Embodiment 2

[0038] A method for reclaiming magnetic separation tailings by preselection-roasting-maglev process of the present invention comprises the following steps:

[0039] 1) Feed the magnetic separation tailings with an iron grade of 12.13% and a carbonate iron content of 4.23% into a section of weak magnetic to obtain a section of weak magnetic concentrate and a section of weak magnetic tailings with a grade of 28.01%; The tailings are fed into a section of strong magnetic to obtain a section of strong magnetic concentrate with a grade of 13.62% and a section of strong magnetic tailings with a grade of 6.53%;

[0040] 2) A section of strong magnetic concentrate is fed into the roughing spiral chute, and the coarse spiral concentrate is fed into the selected spiral chute to obtain the selected spiral chute concentrate, the selected spiral chute medium ore and the selected spiral chute tailings. The middle ore in the spiral chute returns to the selection spiral chute, the tailings of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com