Chemical oil removal liquid suitable for aluminum alloy by utilizing anode oxidation waste sulfuric acid and application of chemical oil removal liquid

A chemical degreasing, anodizing technology, applied in sulfur trioxide/sulfuric acid, inorganic chemistry, sulfur compounds, etc., can solve problems such as ecological environment hazards and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

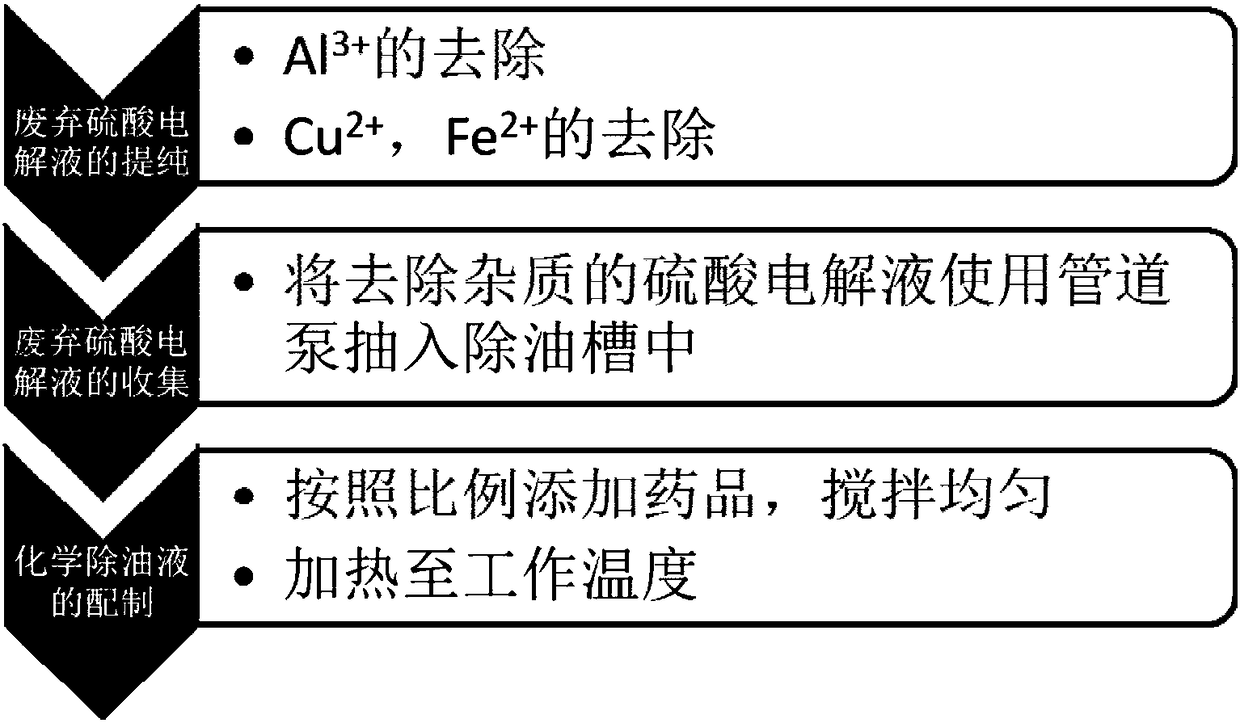

Method used

Image

Examples

Embodiment 1

[0027] (1) Purification of sulfuric acid in the waste liquid of anodic oxidation tank

[0028] The main component of the electrolyte in the sulfuric acid anodic oxidation tank is sulfuric acid. During the sulfuric acid anodic oxidation process to treat the surface of the gas cylinder according to the conventional process, the sulfuric acid electrolyte is inevitably mixed with impurities during use, and some of the impurities will affect the resistance of the oxide film. Corrosion, brightness, hardness and conductivity of the bath. After detection, the main component of the waste liquid in the anodizing tank is sulfuric acid, and the main impurity metal ions are aluminum ions, copper ions and ferrous ions. The impurity metal ions mainly come from the dissolution of matrix metal during anodic oxidation. The impurity metal ions in the waste liquid of the anodizing tank For ordinary sulfuric acid anodization, the maximum allowable content of impurities is shown in Table 1.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com