Preparation method of an organic-coated core-shell nanocomposite hydrogen storage material

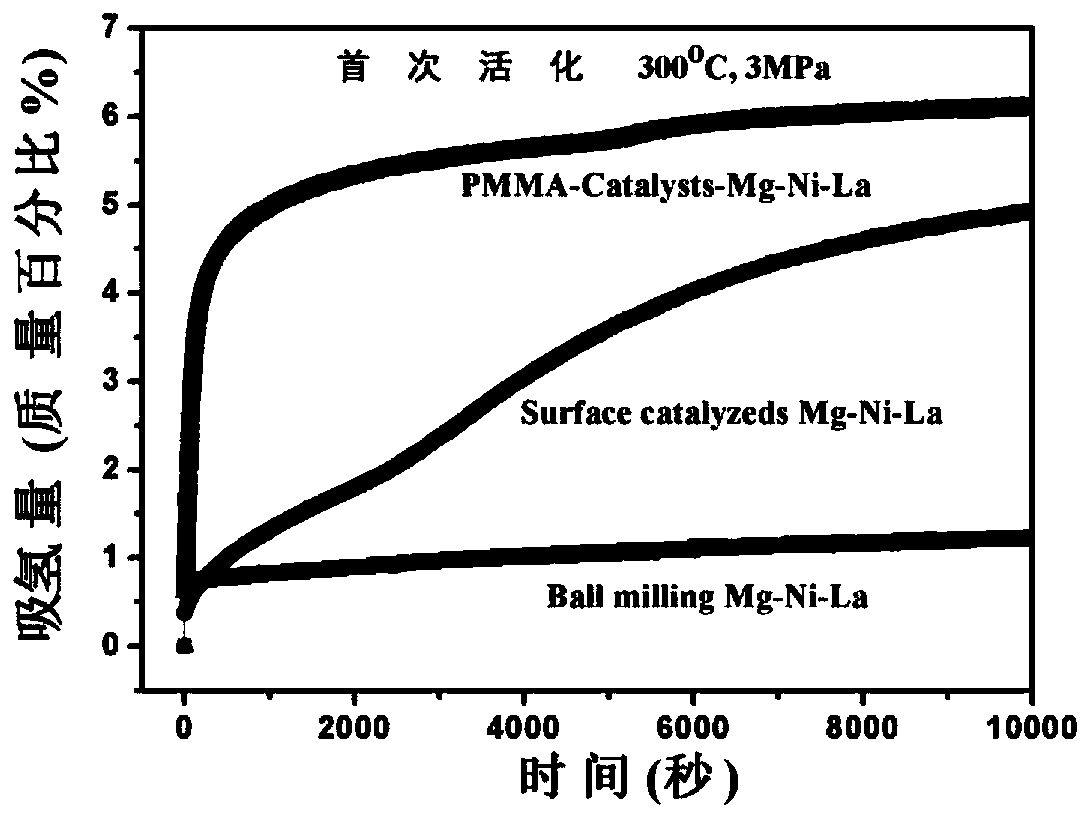

A technology of nanocomposite and hydrogen storage materials, which is applied in the field of preparation of organic-coated core-shell nanocomposite hydrogen storage materials, to achieve the effects of suppressing poisoning, reducing the difficulty of activation, and improving the thermodynamic properties of hydrogen absorption and desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The Mg-Ni-La based composite hydrogen storage alloy powder of the present invention is made of Mg-Ni-La alloy, CNTs and TiF 3 Catalyst composition, Mg-Ni alloy: CNTs: TiF 3 =8:1:1, the ratio is a weight ratio.

[0026] In the alloy belt, in the Mg-Ni-La alloy, the magnesium content is 90 at.%, the lanthanum content is 0-10 at.%, and the rest is nickel. The chemical formula of the alloy is Mg2Ni 1-x La x , 0≤x≤0.5, x=0 in this embodiment.

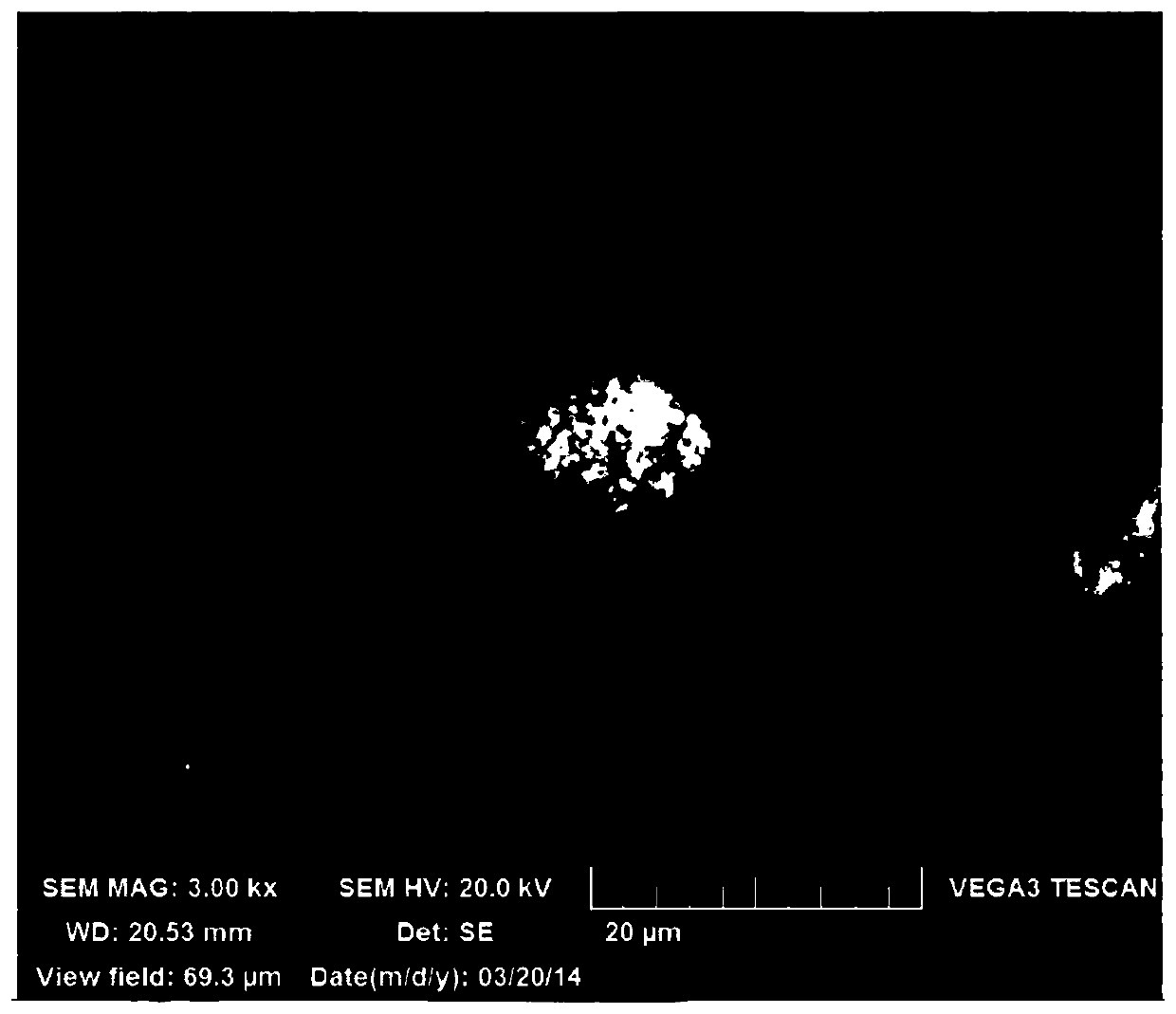

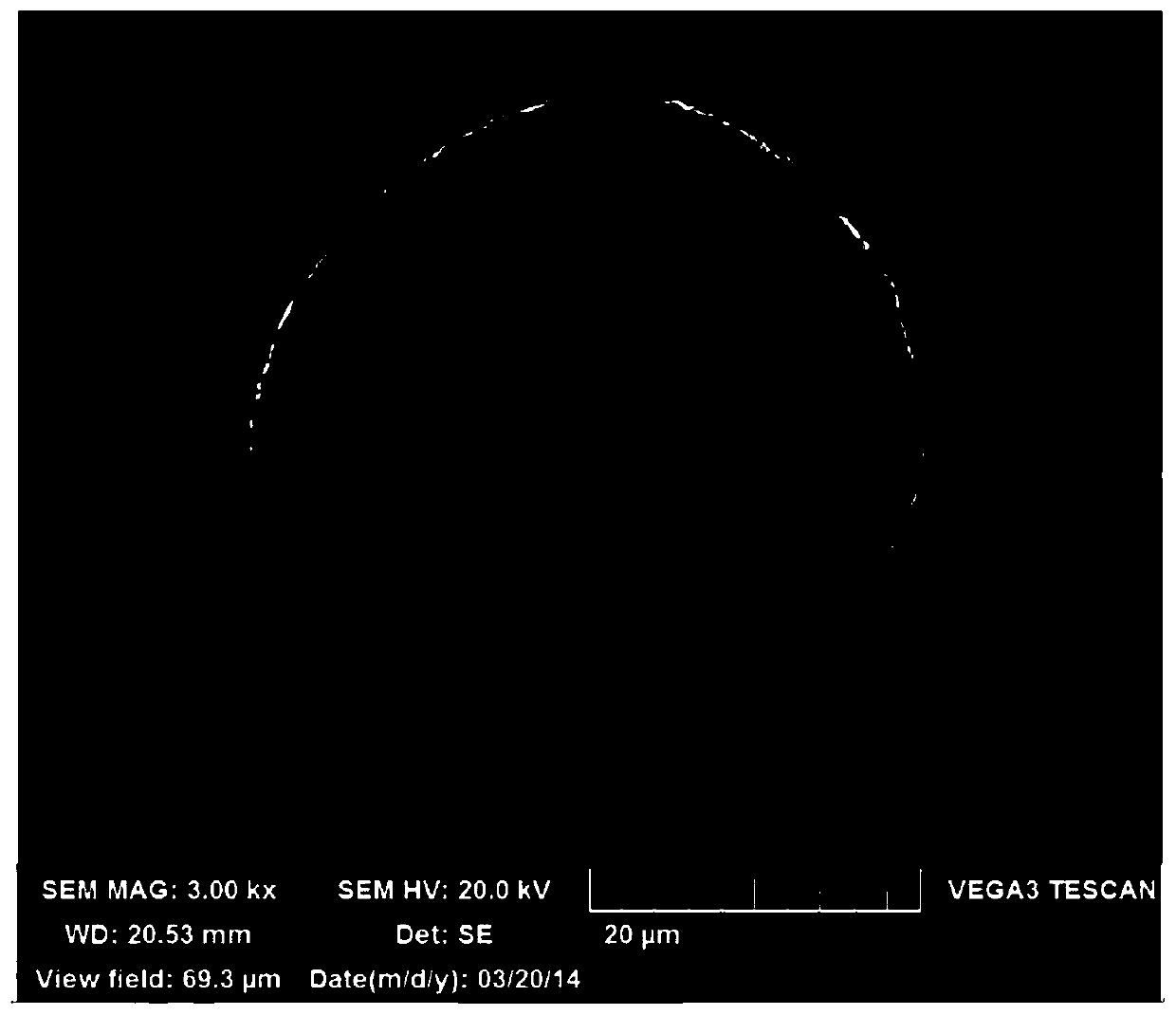

[0027] The invention also proposes a PMMA@CNT-TiF with excellent preparation, activation and cycle characteristics 3 @Mg-Ni-La three-layer core-shell nanocomposite hydrogen storage material, the specific process is:

[0028] Step 1, alloy ingredients: select metal magnesium block and nickel powder with purity ≥ 99.8%, press Mg 2 Ni 0.9 La 0.1 Stoichiometric ratio weighing, considering burning loss, magnesium added 3-5wt.% burning loss. In this embodiment, the addition amount of magnesium for burning loss is 3wt.%. The nickel ...

Embodiment 2

[0033] The Mg-Ni-La based composite hydrogen storage alloy powder of the present invention is made of Mg-Ni-La alloy, CNTs and TiF 3 Catalyst composition, Mg-Ni alloy: CNTs: TiF 3 =8:1:1, the ratio is a weight ratio.

[0034] In the alloy strip, in the Mg-Ni-La alloy, the magnesium content is 90 at.%, the lanthanum content is 0-10 at.%, and the rest is nickel. The chemical formula of the alloy is Mg 2 Ni 1-x La x, 0≤x≤0.5, x=0.1 in this embodiment.

[0035] The invention also proposes a PMMA@CNT-TiF with excellent preparation, activation and cycle characteristics 3 @Mg-Ni-La three-layer core-shell nanocomposite hydrogen storage material, the specific process is:

[0036] Step 1, alloy ingredients: select metal magnesium block and nickel powder with purity ≥ 99.8%, press Mg 2 Ni 0.9 La 0.1 Stoichiometric ratio weighing, considering burning loss, magnesium added 3-5wt.% burning loss. In this embodiment, the addition amount of magnesium for burning loss is 4wt.%. The n...

Embodiment 3

[0041] The Mg-Ni-La based composite hydrogen storage alloy powder of the present invention is made of Mg-Ni-La alloy, CNTs and TiF 3 Catalyst composition, Mg-Ni alloy: CNTs: TiF 3 =8:1:1, the ratio is a weight ratio.

[0042] In the alloy strip, in the Mg-Ni-La alloy, the magnesium content is 90 at.%, the lanthanum content is 0-10 at.%, and the rest is nickel. The chemical formula of the alloy is Mg 2 Ni 1-x La x , 0≤x≤0.5, x=0.3 in this embodiment.

[0043] The invention also proposes a PMMA@CNT-TiF with excellent preparation, activation and cycle characteristics 3 @Mg-Ni-La three-layer core-shell nanocomposite hydrogen storage material, the specific process is:

[0044] Step 1, alloy ingredients: select metal magnesium block and nickel powder with purity ≥ 99.8%, press Mg 2 Ni 0.7 La 0.3 Stoichiometric ratio weighing, considering burning loss, magnesium added 3-5wt.% burning loss. In this embodiment, the addition amount of magnesium for burning loss is 5wt.%. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com