Suspended silicon fertilizer and preparation method and device

A silicon fertilizer and bio-silicon technology, applied in fertilization devices, botany equipment and methods, organic fertilizers, etc., can solve problems such as inability to maintain balance, failure to replenish silicon in time, etc., to eliminate heavy metal pollution, improve lodging resistance, The effect of enhancing ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of suspension silicon fertilizer, comprises Aoli silicon particle (containing silicon dioxide 72%) 30g, wetting agent MSR-TT12g; Dispersant MSD-511 4g; Thickener xanthan gum 0.2g, antifreeze agent propylene glycol 4g, water 159.8g.

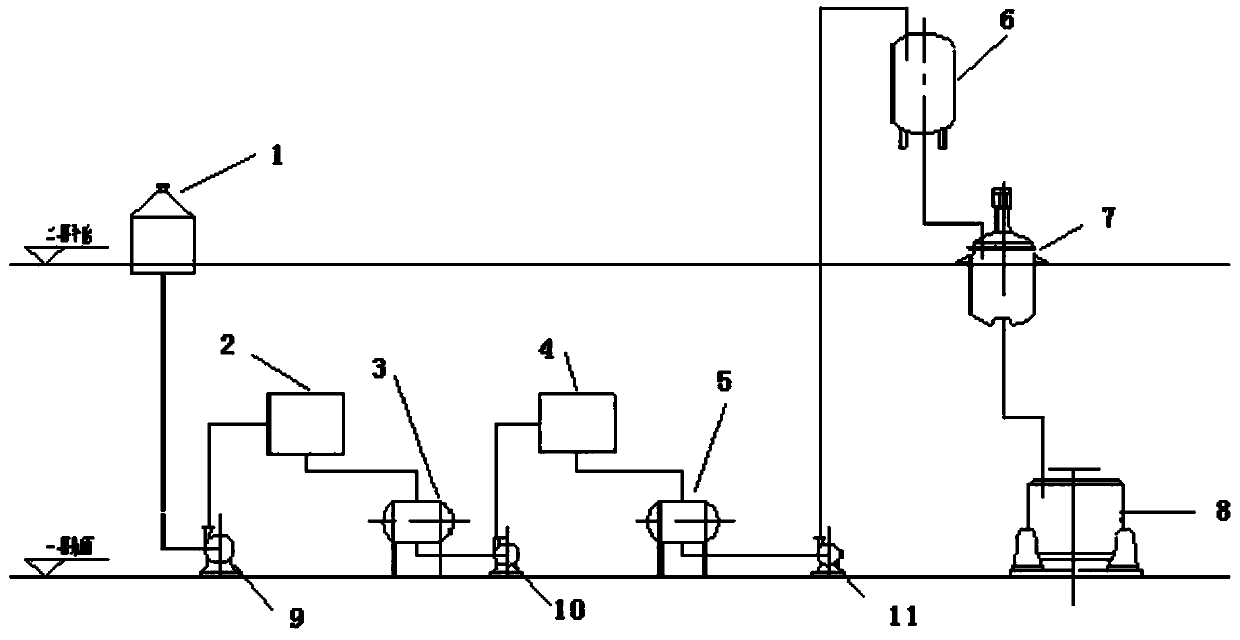

[0036] The method for preparing above-mentioned suspended silicon fertilizer, refer to figure 1 , including the following steps:

[0037] 1) Add water to the high-speed shear 1, add "bio-silicon" and soak for 30 minutes, start the high-speed shear 1, adjust the speed to 200r / min, add the weighed wetting agent, dispersant, thickener in sequence, and shear Cut for 40 minutes;

[0038] 2) Add antifreeze to the high-speed shearing machine 1, continue to shear for 20min, and the shearing speed is 200r / min;

[0039] 3) After the shearing is completed, the sheared material is pumped into the primary sand mill 2 for grinding through the first pipeline pump 9, and the ground material enters the primary sand grinding storage tank 3;

[004...

Embodiment 2

[0044] The difference with embodiment 1 is:

[0045] A kind of suspension silicon fertilizer, comprises Aoli silicon granule (containing silicon dioxide 72%) 34g, wetting agent MSR-TT13g; Dispersant MSD-511 6g; Thickener xanthan gum 0.5g, antifreeze agent propylene glycol 6g, water 150.5g.

Embodiment 3

[0047] The difference with embodiment 1 is:

[0048]A kind of suspension silicon fertilizer, comprises Aoli silicon granule (containing silicon dioxide 72%) 40g, wetting agent MSR-TT14g; Dispersant MSD-511 8g; Thickener xanthan gum 0.8g, antifreeze agent propylene glycol 8g, water 139.2g.

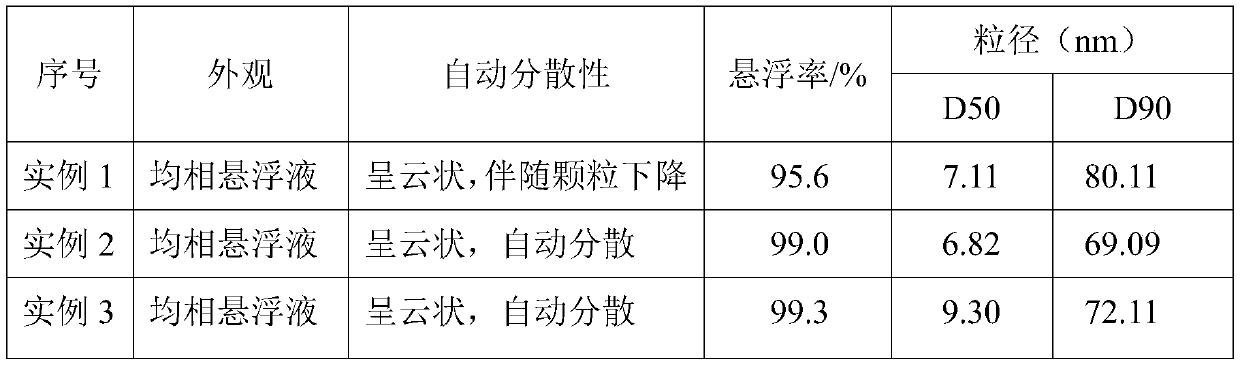

[0049] The products prepared in Example 1, Example 2 and Example 3 were tested, the results are shown in the table below, the dispersion is good, and the particles reach the nanoscale.

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com