A flame-retardant ABS resin-based barrier explosion-proof material suitable for metal coating and preparation method thereof

A technology for blocking explosion-proof materials and ABS resin, applied in the direction of coating, etc., to achieve reliable performance, simple molding industry, and avoid combustion or explosion accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A flame-retardant ABS resin-based barrier explosion-proof material suitable for metal coating, said flame-retardant ABS resin-based barrier explosion-proof material suitable for metal coating comprises ABS resin, flame retardant system, lubricant and antiaging agent, by weight In terms of parts, 100 parts of ABS resin, 25-45 parts of flame retardant system, 0-5.0 parts of lubricant, and 0.2-0.6 parts of antioxidant.

[0024] The molar ratio of butadiene in the ABS resin is 15-25%, and the melting index of the ABS is 1.5-35g / 10min. The flame retardant system is classified into a halogen-free flame retardant system or a halogenated flame retardant system. The lubricant is silicone powder, the mass fraction of silicon and silicon compounds contained in the silicone powder is not less than 95%, and the average particle size of the silicone powder is not more than 20 μm. The antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, and the purity of the ant...

Embodiment 2

[0028] A method for preparing a flame-retardant ABS resin-based barrier explosion-proof material suitable for metal coating, comprising the steps of:

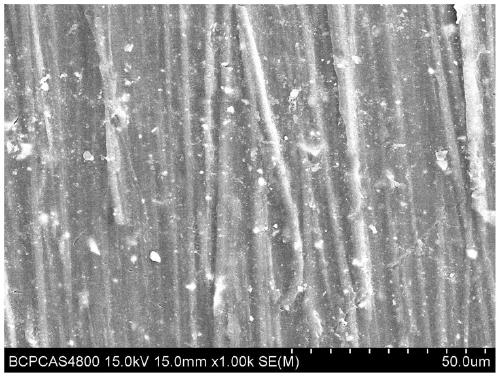

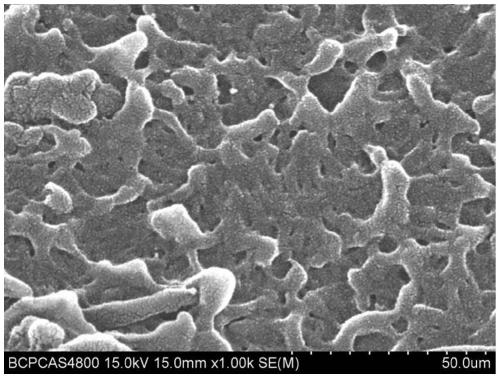

[0029] (1) First dry the ABS resin particles at 75-85°C for 2 hours; (2) In terms of parts by mass, 100 parts of ABS resin, 25-45 parts of flame retardant system, 0-5.0 parts of lubricant, Add 0.2 to 0.6 parts of oxidant into the mixer, and after uniform mixing, melt and blend through a twin-screw extruder, control the extrusion temperature not higher than 240°C, and obtain flame-retardant modified ABS resin particles; (3) flame-retardant modified ABS resin particles are prepared by injection molding to obtain the barrier explosion-proof material; (4) the surface of the barrier explosion-proof material prepared by injection molding is covered with a layer of nickel and chromium metal by plastic electroplating or chemical plating process.

Embodiment 3

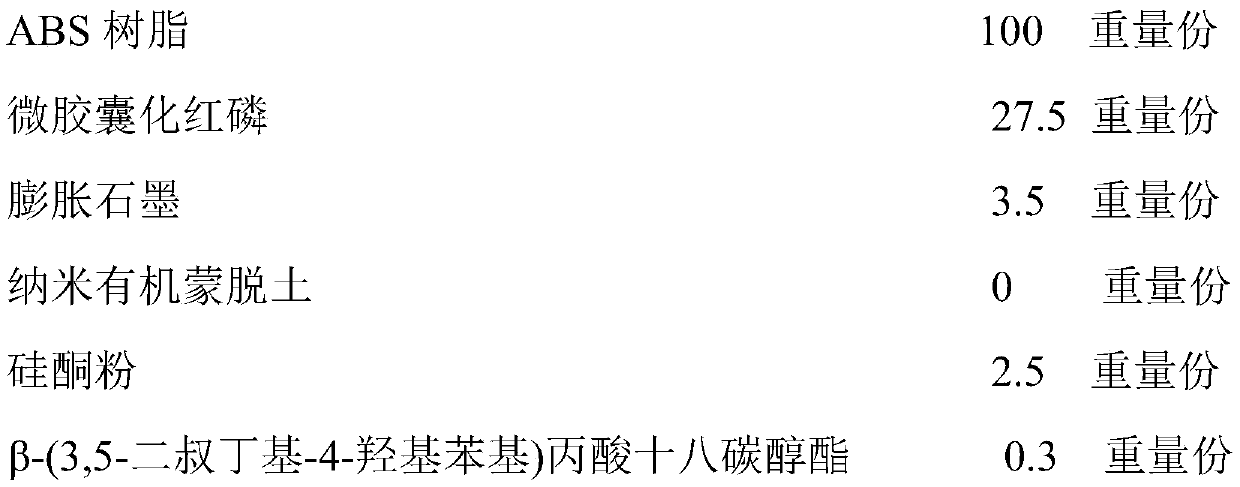

[0031] The flame-retardant ABS resin-based barrier explosion-proof material component suitable for metal coating includes the following components, in parts by weight:

[0032]

[0033] Weigh each component according to the above weight, place it in a high-speed mixer and mix for 2 minutes, and then put the uniformly mixed components into a twin-screw extruder for granulation. The twin-screw is produced by Nanjing Jieent Electromechanical Co., Ltd. The SHF-30 type. The speed of the screw machine is 400 rpm, and the temperature control of each section of the extruder is as follows: the barrel temperature is 160°C in the first zone, 1650°C in the second zone, 170°C in the third zone, 175°C in the fourth zone, 180°C in the fifth zone, and 190°C in the head After extrusion and granulation, the prepared flame-retardant ABS resin particles are injection-molded into the required skeleton-shaped thin-walled spherical barrier explosion-proof material, and finally the barrier explosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com