A kind of shale stabilizer and preparation method thereof

A stabilizer and mud shale technology, which is applied in the field of mud shale stabilizer and its preparation, can solve the problems of high concentration, difficult to take into account at the same time, single action form, etc., to achieve improved dispersion stability, controllable synthesis conditions, principle reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

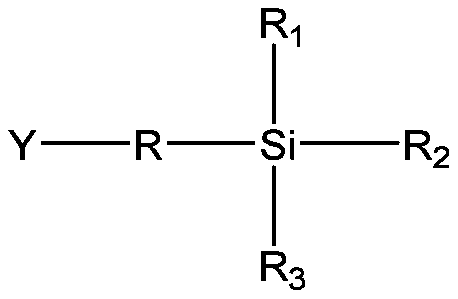

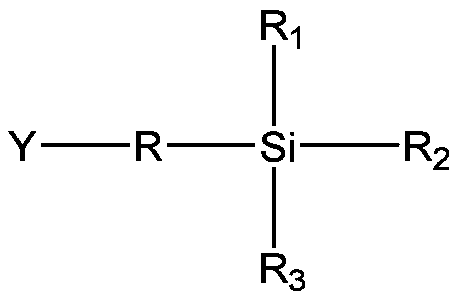

[0054] The present invention also relates to a kind of preparation method of the nano-silica modified by dendrimers, comprising the steps of:

[0055] (1) Dry the nano silicon dioxide in a vacuum drying oven, then cool to room temperature, and place it in a desiccator for later use.

[0056] Wherein, the drying temperature of the vacuum drying oven is 100-120° C., and the drying time is more than 12 hours.

[0057] (2) Add dry nano silicon dioxide into anhydrous organic solvent, and ultrasonically disperse to obtain a uniform suspension.

[0058] Wherein, the organic solvent may be anhydrous toluene; the nano silicon dioxide is 1-6w / v% of the solvent.

[0059] (3) Put the suspension obtained in step (2) into a flask, add a silane coupling agent, stir under a nitrogen atmosphere, and heat to react to obtain a first mixture.

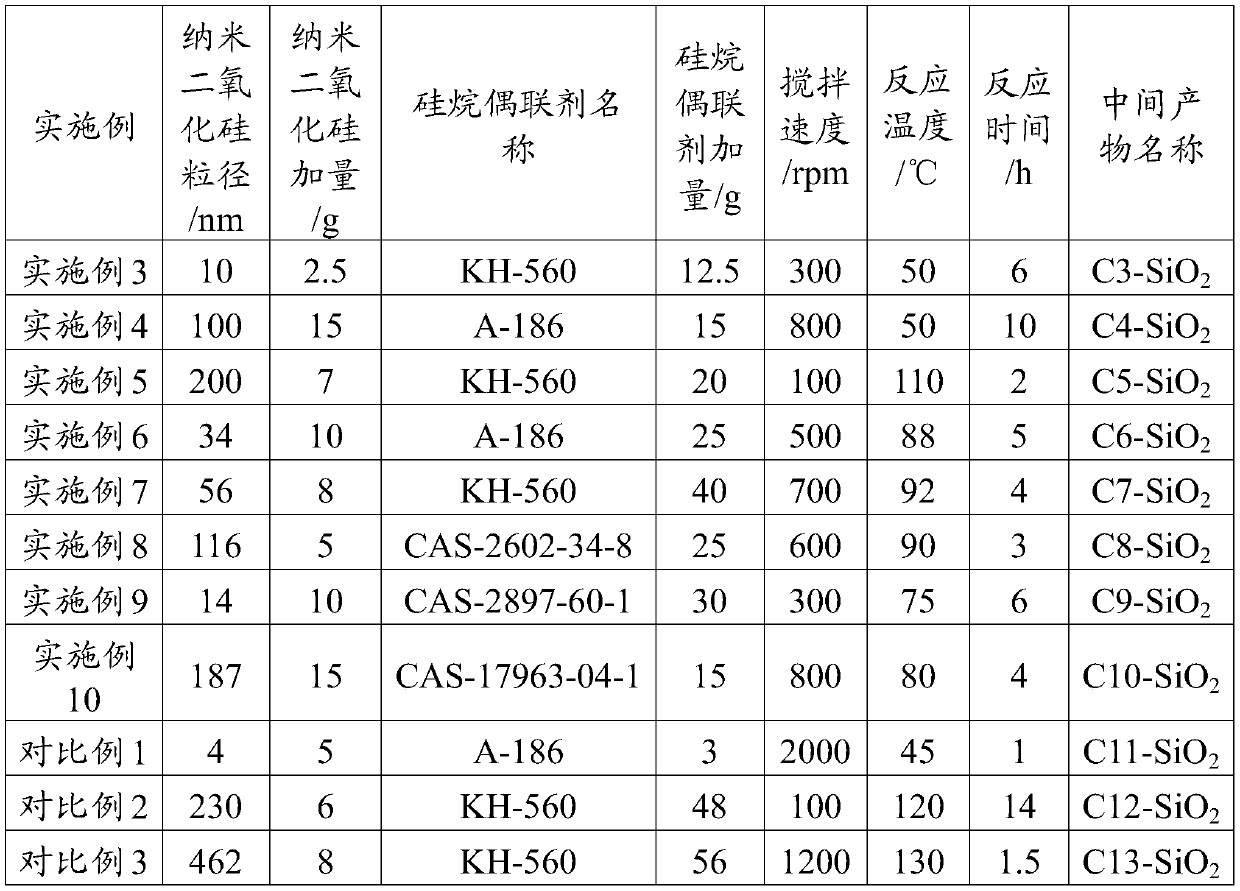

[0060] Wherein, the mass ratio of the silane coupling agent to the nano-silicon dioxide is 1:1 to 5:1; the heating reaction is to react at 50 to 100°C f...

Embodiment 1

[0069] (1) Place nano-silica with a particle size of 12nm in a vacuum drying oven at 105°C for 12 hours, then cool to room temperature, and place in a desiccator for later use;

[0070] (2) Add 250mL of anhydrous toluene and 10g of dry nano-silica in a beaker, and use SB-3200DT ultrasonic cleaner to disperse ultrasonically for 30min at room temperature to obtain a uniform suspension;

[0071] (3) Put the suspension obtained in step (2) into a four-necked flask with a stirrer, condenser, thermometer and nitrogen gas guide tube, add 15g of silane coupling agent β-(3,4 epoxycyclohexyl) Ethyltrimethoxysilane (purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., commercial name is A-186), stirred under a nitrogen atmosphere, the stirring speed was set at 800rpm, heated to 95°C by a water bath and maintained at a stable temperature , reacted for 2h to obtain the first mixture;

[0072] (4) The first mixture obtained in step (3) is washed with ethanol, centrifuged 3 tim...

Embodiment 2

[0076] (1) Put the nano-silica with a particle size of 5nm in a vacuum drying oven at 105°C for 12 hours, then cool to room temperature, and put it in a desiccator for later use;

[0077] (2) Add 250mL of anhydrous toluene and 10g of dry nano-silica in a beaker, and use SB-3200DT ultrasonic cleaner to disperse ultrasonically for 30min at room temperature to obtain a uniform suspension;

[0078] (3) Put the suspension obtained in step (2) into a four-necked flask with a stirrer, condenser, thermometer and nitrogen gas guide tube, add 20g of silane coupling agent γ-glycidyl ether oxypropyl trimethoxy Silane (purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., commercial name is KH-560), stirred under a nitrogen atmosphere, the stirring speed was set at 100rpm, heated to 90°C in a water bath and kept at a stable temperature, reacted for 2h, and obtained the first mixture;

[0079] (4) The first mixture obtained in step (3) is washed with ethanol, centrifuged 3 time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com