Device for treating oily wastewater by photocatalytic-oxidation composite diatomite-based nano-ceramics and method

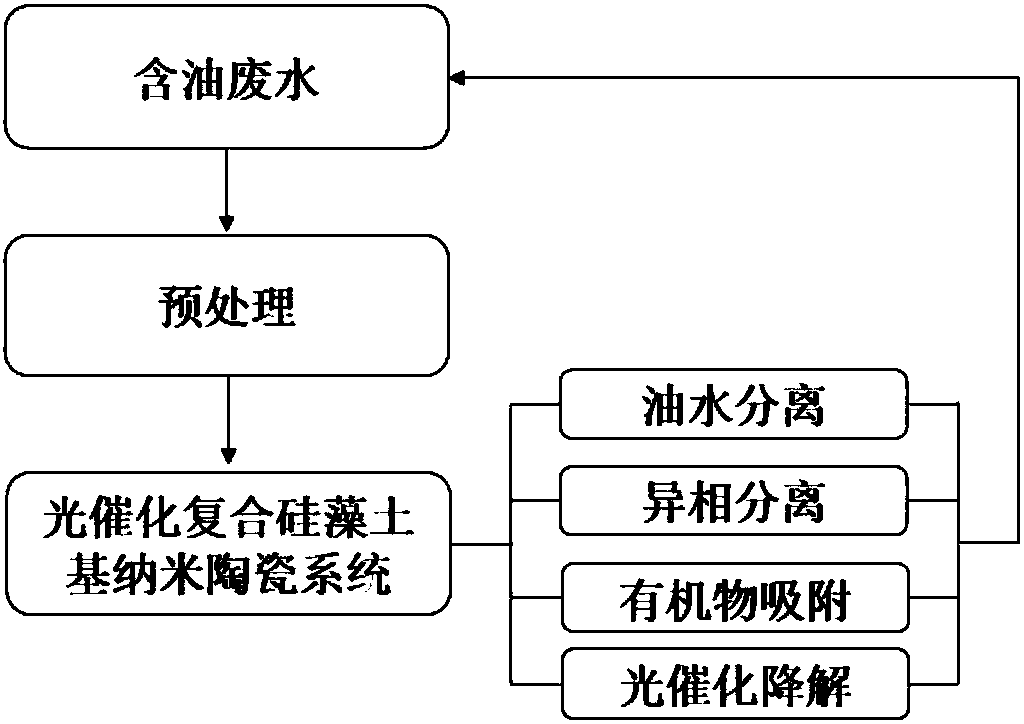

A technology of photocatalytic oxidation and composite diatomite, which is applied in the field of water treatment, can solve the problems of increased floor area and maintenance cost, secondary pollution, and repeated times, so as to save the floor area and cost of treatment, and reduce the treatment cost. Cost, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

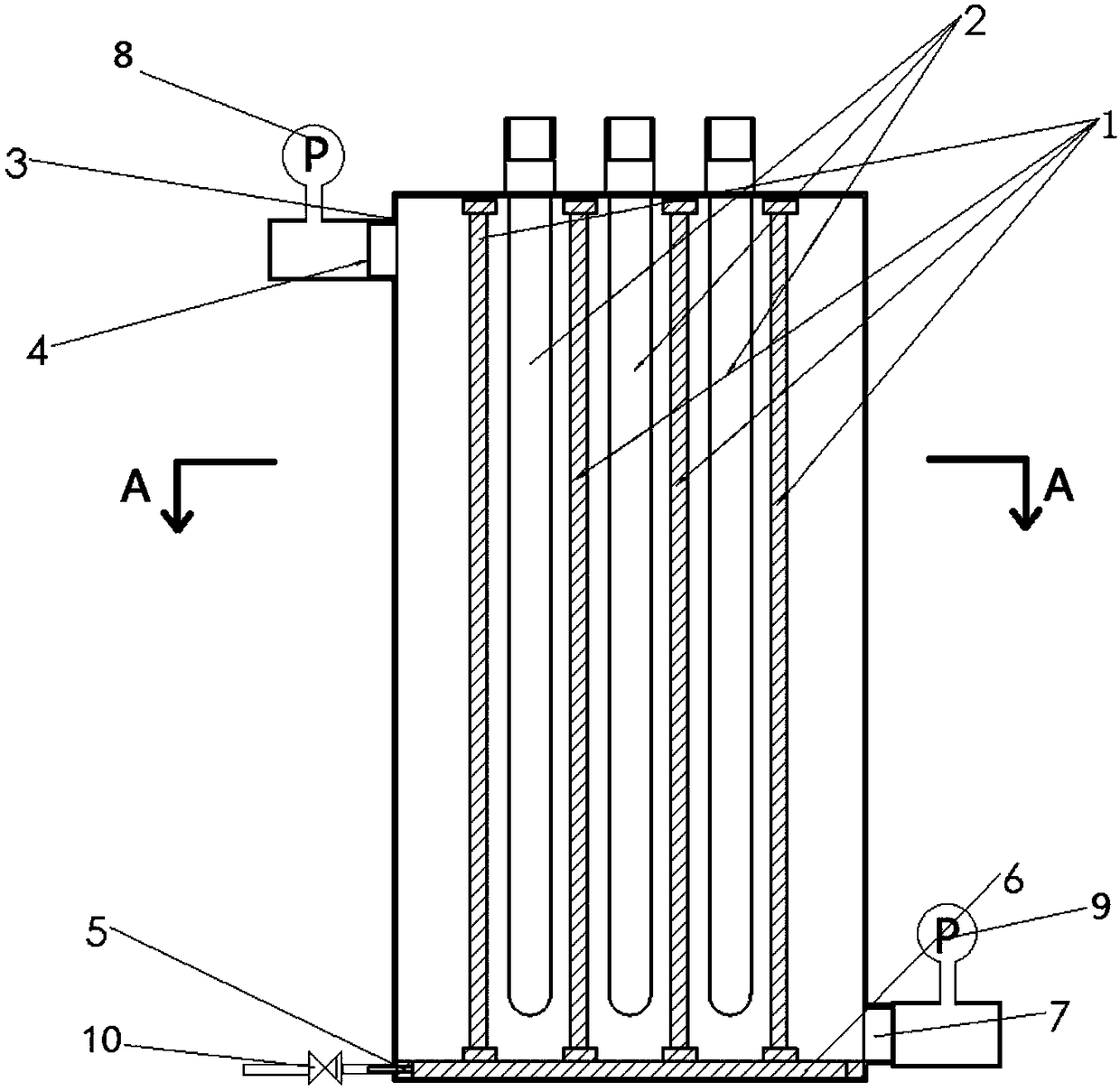

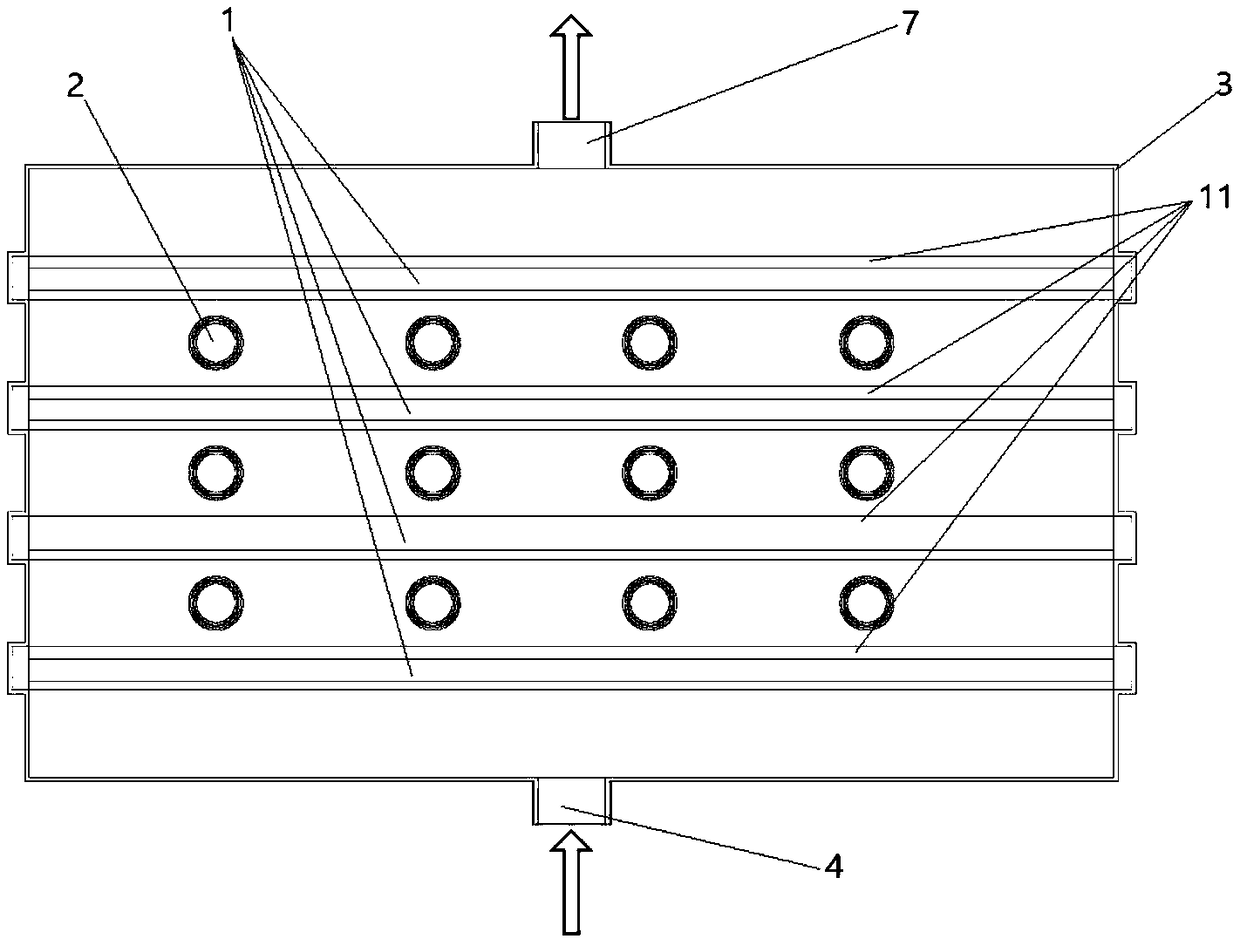

Embodiment 1

[0051] It was taken from oily wastewater from an oil field. The oily wastewater had an oil content of 10%, a pH of 9.28, and a COD of 1263 mg / L, all of which failed to meet the standards. The oily wastewater is first filtered through a filter with a pore size of 100 μm, and then enters the photocatalytic oxidation composite diatomite-based nano-ceramic system 1 through the water inlet 4, and the compressed air in the reaction system enters the aeration ceramic 6 through the air inlet 5, and the aeration The ceramics are quartz aerated ceramics with a flow rate of 100L / h. The light source of the ultraviolet lamp 2 is a low-pressure mercury lamp with a dominant emission wavelength of 254nm. The chemical composition of the diatomite-based nano-ceramic 1 is The pore size of the ceramic is 0.5 μm, and the nano photocatalytic material loaded on the surface of the ceramic is titanium dioxide photocatalytic powder. The photocatalytic oxidation composite nano ceramic is fixed in the ...

Embodiment 2

[0053] The drilling fluid is taken from an offshore drilling platform. The relevant physical and chemical parameters of the drilling fluid: oil content is 12%, pH value is 6.89, COD is 15000mg / L, suspended solids is 500mg / L, etc. The relevant indicators have not reached GB 4914-2008《 Discharge standards in "Limits of Pollutant Discharge Concentration Values for Offshore Oil Exploration and Development". The oily wastewater first goes through the pretreatment step to remove large particles of solid matter, and enters the photocatalytic oxidation composite diatomite-based nano-ceramic 1 system through the water inlet 4, and the compressed air in the system enters the aeration ceramic 6 through the air inlet 5, and the aeration The ceramics are quartz aerated ceramics, the aeration flow rate is 150L / h, the ultraviolet light source 2 uses a 254nm low-pressure mercury lamp, and the main chemical composition of the diatomite-based nano-ceramic 1 is The pore size of the ceramic is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com