High-efficiency in situ biogas slurry denitrification method for anaerobic digestion of sludge

An anaerobic digestion and sludge technology, applied in anaerobic digestion treatment, chemical instruments and methods, sludge treatment and other directions, can solve problems such as no related reports, achieve high process stability, promote hydrolysis process, meet carbon The effect of the demand on the source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

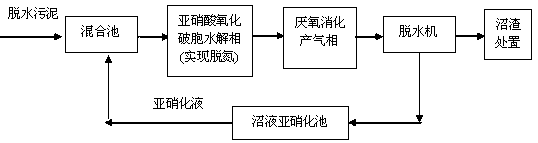

Image

Examples

Embodiment 1

[0036] The dewatered sludge of a sewage treatment plant has a solid content of 25% (moisture content of 75%) and is treated by anaerobic digestion process. After anaerobic digestion and dehydration, the ammonia nitrogen content in the biogas slurry is 3000mg / L, and the ammonia nitrogen nitrosation is realized under the conditions of 30°C, DO=0.3~0.8mg / L, HRT=24h using the original temperature of the biogas slurry. The conversion rate of ammonia nitrogen can reach 95%. The biogas slurry after nitrosation is mixed with fresh dewatered sludge (with a solid content of 25%), and the mixed sludge has a solid content of 15%, and enters the nitrous acid oxidative hydrolysis phase of the sludge anaerobic digestion system. The nitrous acid oxidative hydrolysis phase controls the temperature at 75°C and the residence time is 2 days. A large amount of sludge disintegrates and dissolves organic matter in this phase, and nitrite oxidizes macromolecular organic matter, which is reduced to ni...

Embodiment 2

[0038]The dewatered sludge of a sewage treatment plant has a solid content of 20% (moisture content of 80%) and is treated by anaerobic digestion process. After anaerobic digestion and dehydration, the ammonia nitrogen content in the biogas slurry is 2400mg / L. Using the original temperature of the biogas slurry, the ammonia nitrogen nitrosation is realized under the conditions of 30°C, DO=0.3~0.8mg / L, and HRT=20h. The conversion rate of ammonia nitrogen can reach 95%. The biogas slurry after nitrosation is mixed with fresh dewatered sludge (with a solid content of 20%), and the mixed sludge has a solid content of 13%, and enters the nitrous acid oxidative hydrolysis phase of the sludge anaerobic digestion system. The nitrous acid oxidative hydrolysis phase controls the temperature at 55°C, and the residence time is 3 days. A large amount of sludge disintegrates and dissolves organic matter in this phase, and nitrite oxidizes macromolecular organic matter, which is reduced to n...

Embodiment 3

[0040] The dewatered sludge of a sewage treatment plant has a solid content of 17% (moisture content of 83%) and is treated by anaerobic digestion process. After anaerobic digestion and sludge dehydration, the ammonia nitrogen content in the biogas slurry is 2000mg / L. Using the original temperature of the biogas slurry, the ammonia nitrogen nitrosation is realized under the conditions of 30°C, DO=0.3~0.8mg / L, and HRT=18h. The conversion rate of ammonia nitrogen can reach 95%. The biogas slurry after nitrosation is mixed with fresh dewatered sludge (17% solid content), and the mixed sludge has a solid content of 10%, and enters the nitrous acid oxidative hydrolysis phase of the sludge anaerobic digestion system. The nitrous acid oxidative hydrolysis phase controls the temperature at 35-37°C, and the residence time is 4 days. In this phase, a large amount of disintegration and dissolution of organic matter occurs in the sludge. The nitrite oxidizes the macromolecular organic mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com